-

Wheels and castors

-

Wheels

- Solid Rubber Wheels

- Thermoplastic Wheels

- Polyurethane Wheels

- Air Wheels and Puncture-Proof Wheels

- Plastic Wheels

- Wheels with Stainless Steel Ball Bearings

- ESD Wheels

- Heat-Resistant Wheels

- Heavy-Duty Wheels

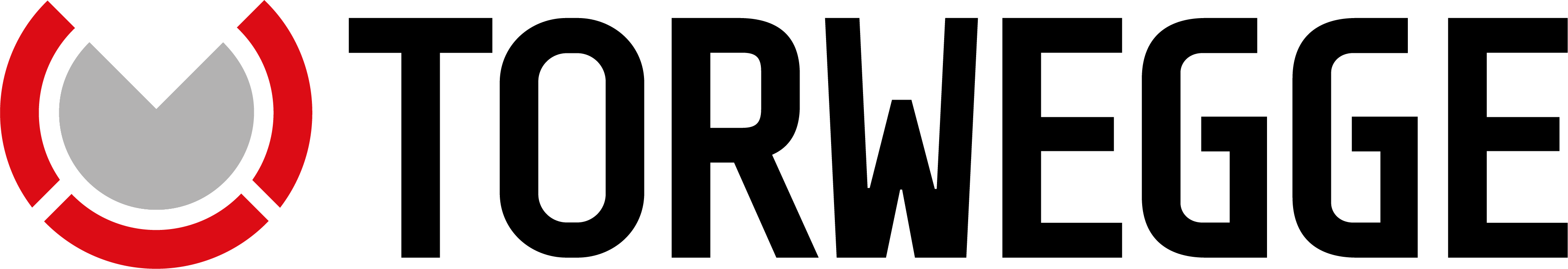

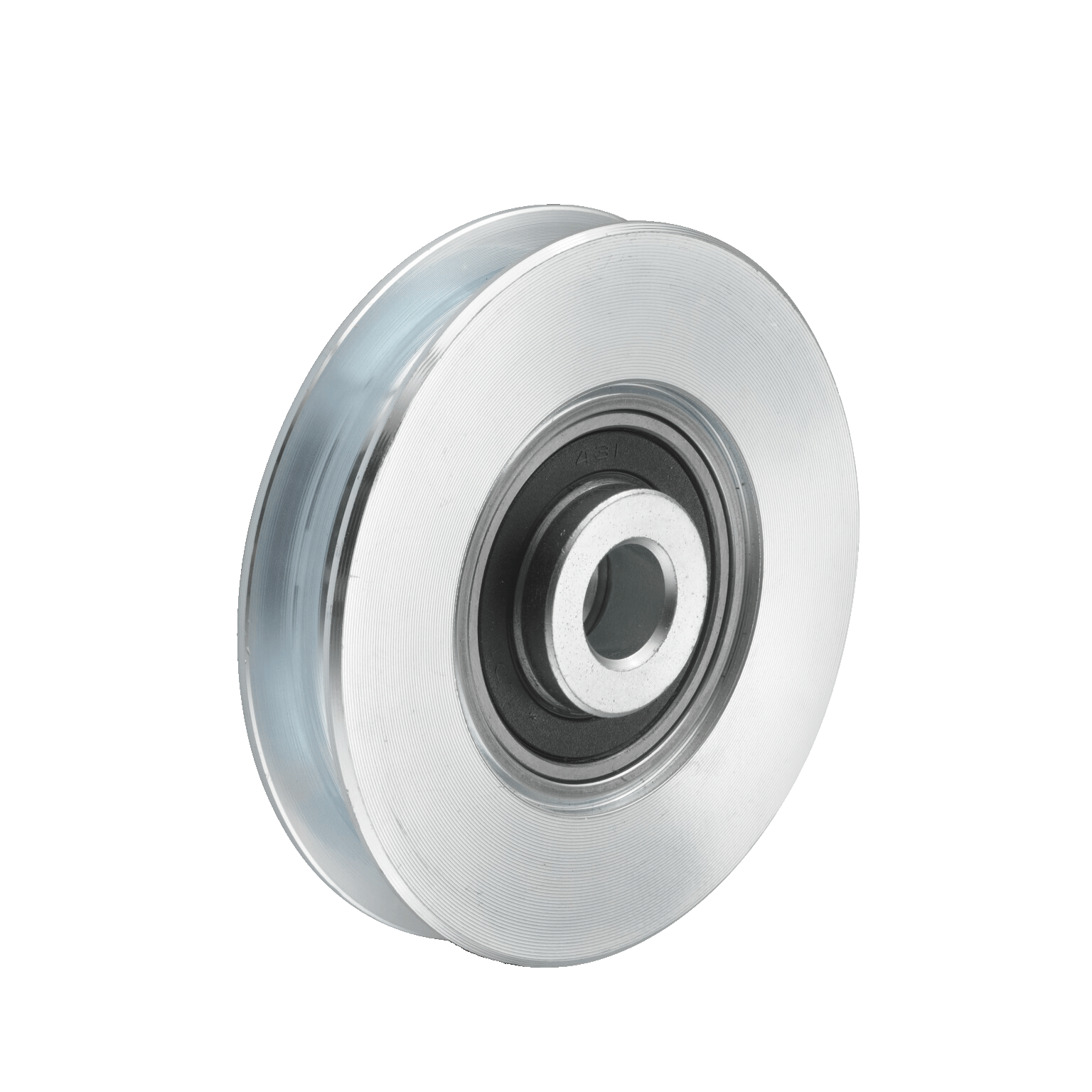

- Guide Rollers

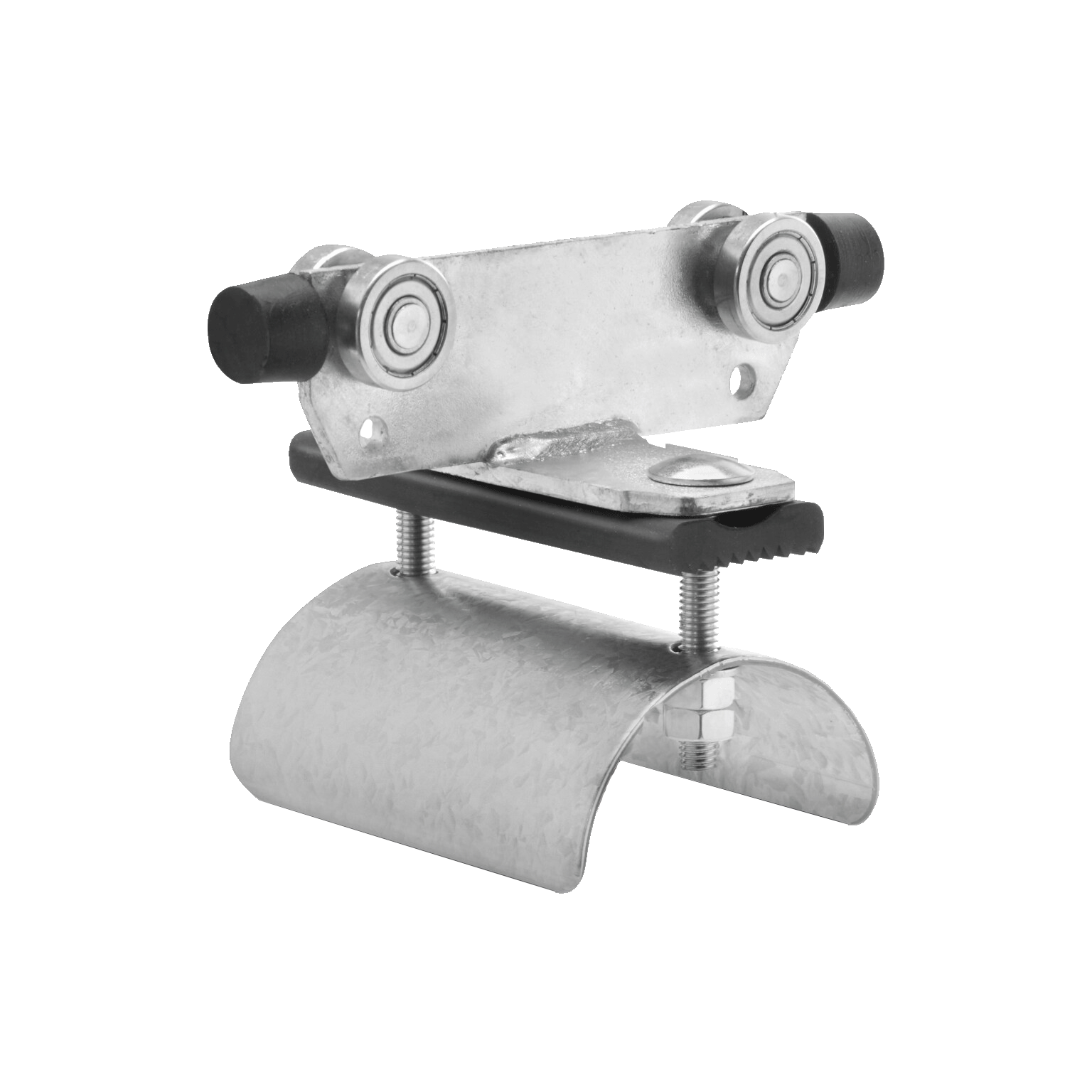

- Door Rollers

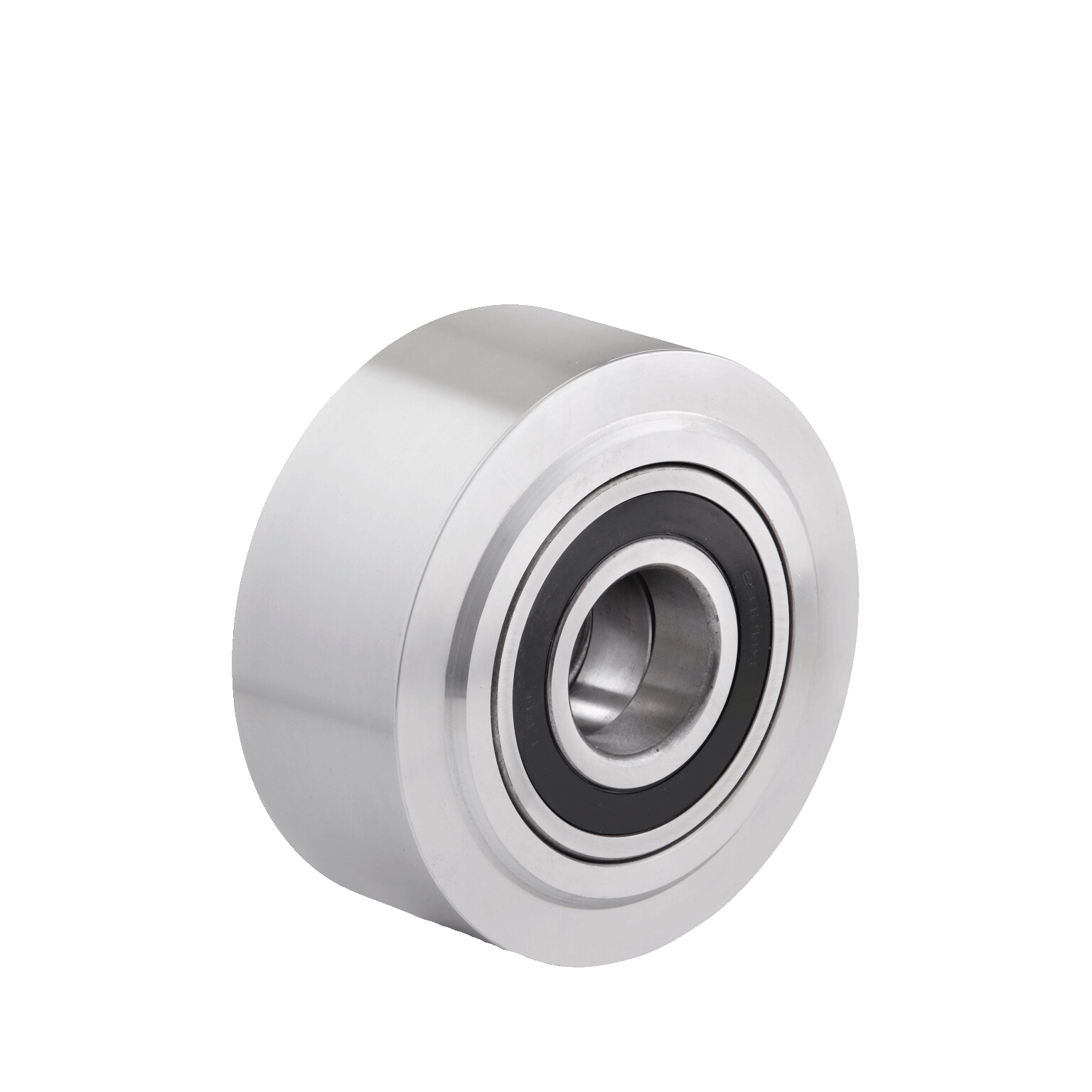

- Track Rollers

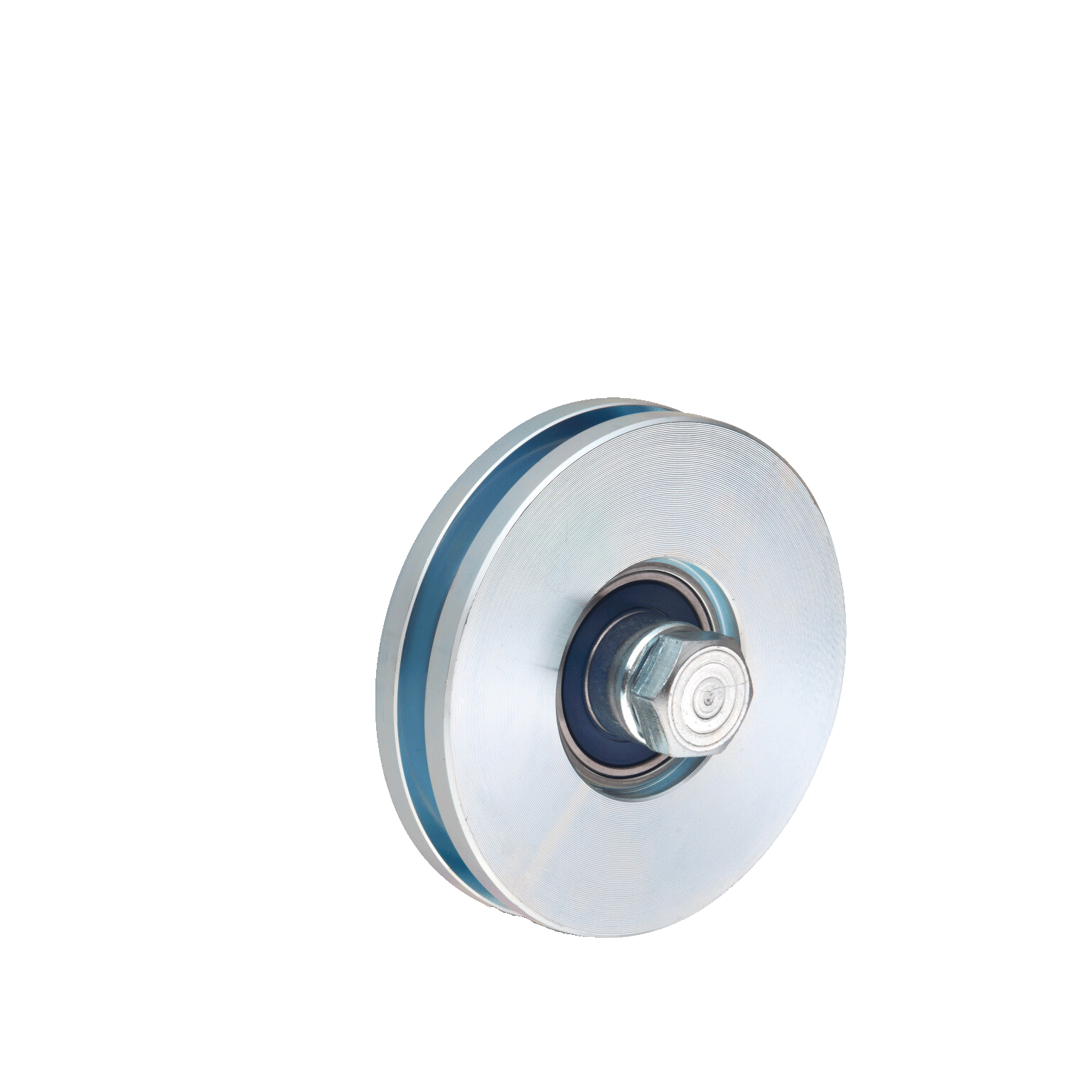

- Rope Pulleys

- Pressure Rollers

- Flange Wheels

- Pallet Truck Rollers

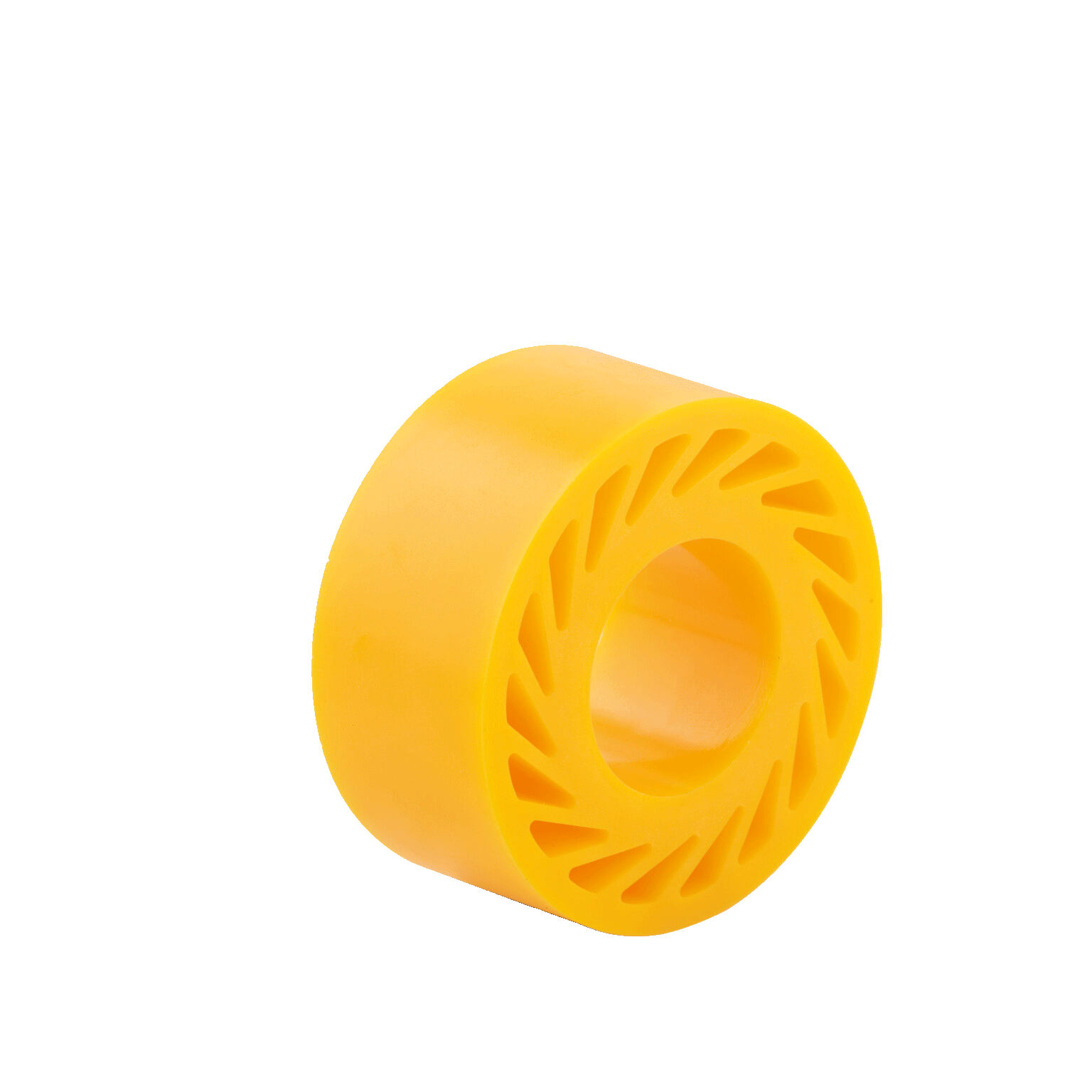

- Drive Wheels

- Bands

- Casters

- Accessories for Wheels and Castors

-

Wheels

- Conveyor Technology

- Transport Technology

- Handling Technology

High-Quality Wheels at TORWEGGE

Buy high-quality wheels online now at TORWEGGE!

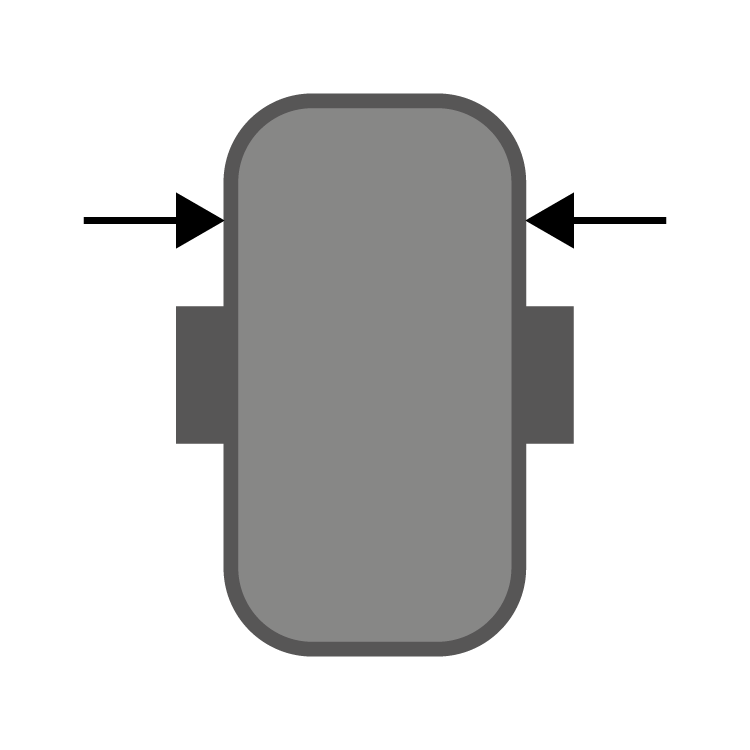

150 kg to 700 kg

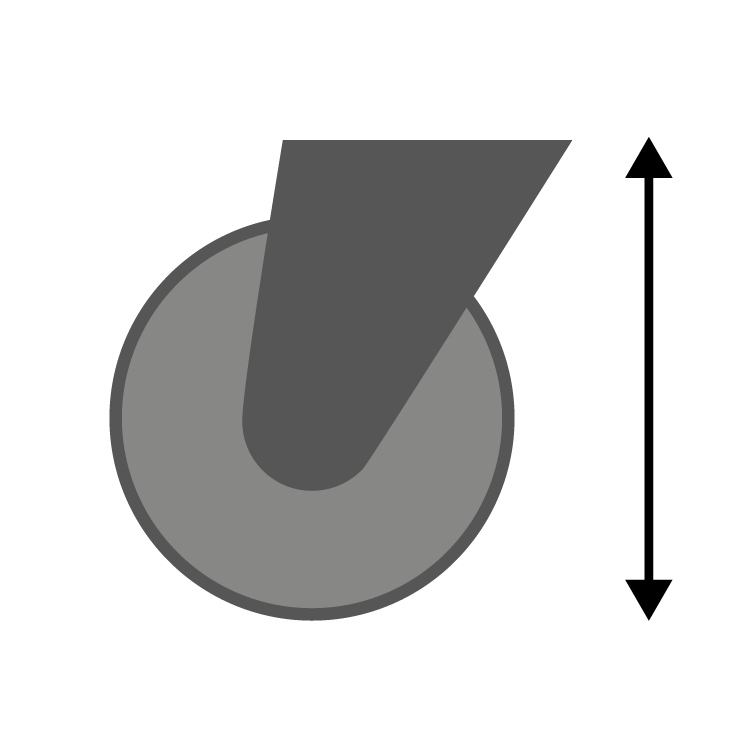

80 mm to 250 mm

35 mm to 60 mm

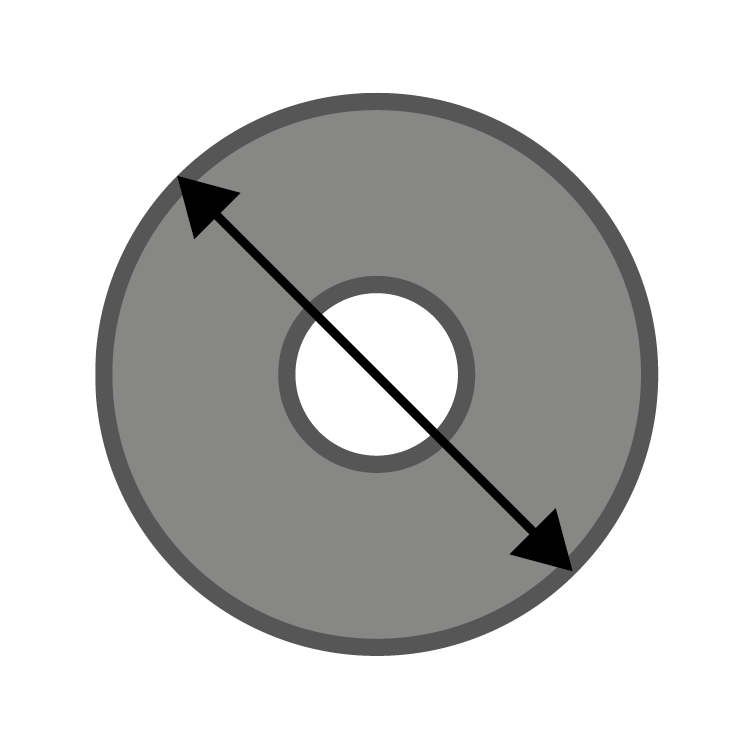

120 kg to 650 kg

80 mm to 300 mm

38 mm to 60 mm

40 mm

12 mm

35 kg

200 kg to 200 kg

400 mm to 400 mm

90 mm to 100 mm

125 kg to 200 kg

245 mm to 260 mm

75 mm to 85 mm

Applications of Wheels and What to Consider When Choosing Them

Our wheels can be used both indoors and outdoors on various surfaces. The wide range of different models offers a solution for every requirement.

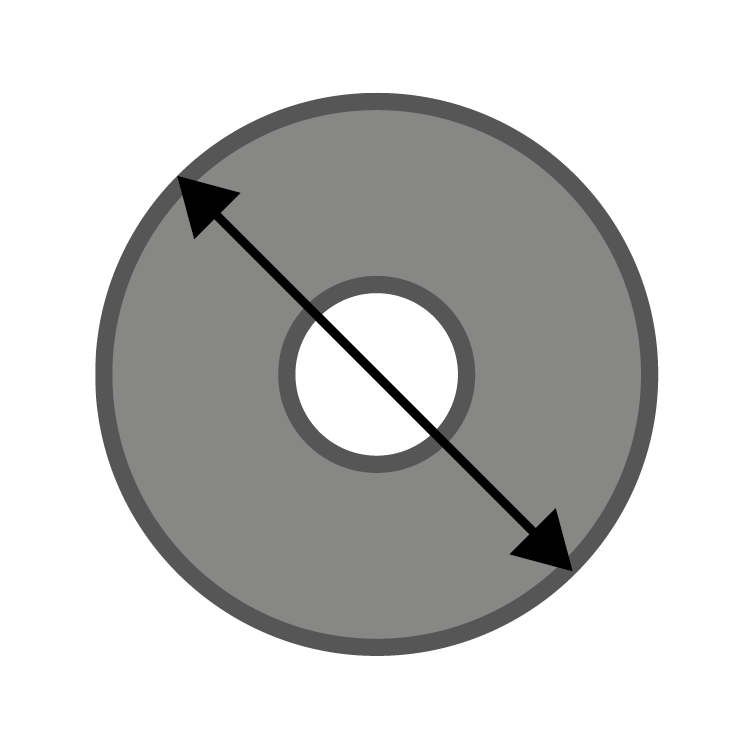

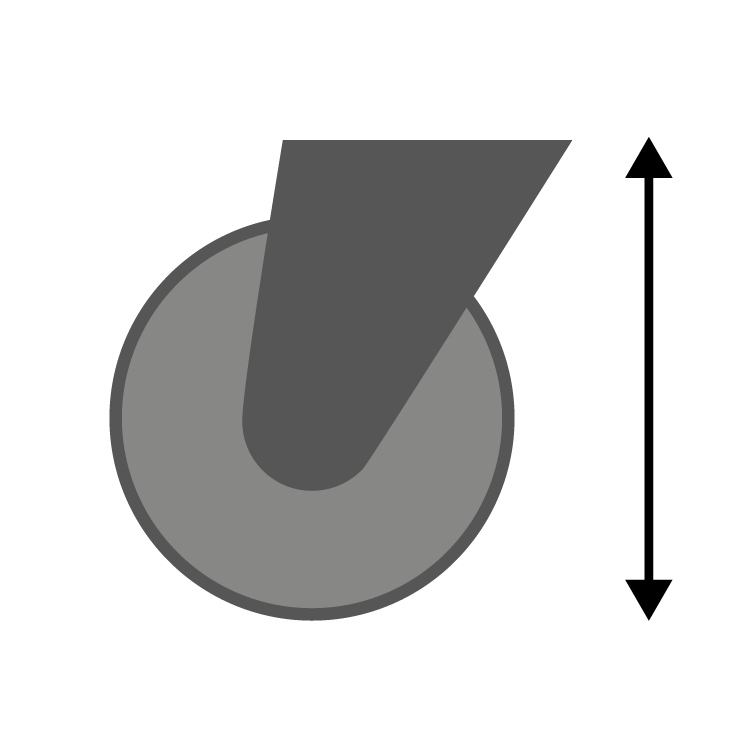

Wheels differ in design from castors, as they are mounted directly onto an axle. In general, all our TORWEGGE wheels can be attached to carts or other transport objects to move goods with ease. When selecting the right wheel, you should first consider the type and condition of your floor, as well as the overall environment in which it will be used.

A wheel used in a warehouse with consistent temperatures and smooth floors experiences different demands than one used outdoors year-round on rough surfaces, whether in winter or summer. Therefore, it is essential to consider environmental factors when selecting a wheel. The condition of the surface is particularly important when determining the wheel diameter and tire material. As a general rule: the larger the wheel diameter and the more elastic the material, the better it can handle surface irregularities. Consequently, wheels primarily used outdoors are typically larger and softer than those designed for indoor use.

If wheels come into contact with chemicals, the materials used must be suitably resistant. For instance, rubber is not resistant to petroleum, whereas polypropylene, polyamide, and polyurethane are. On the other hand, rubber is resistant to acetone, unlike polyurethane. Moisture exposure is another critical factor. Steels commonly used in wheel and castor manufacturing have little resistance in damp environments, which is why their surfaces are treated with a protective coating. Furthermore, not all materials are suitable for the same temperature ranges. In general, the load capacity and durability of tread materials decrease at higher temperatures, particularly for plastics. However, there are materials designed to withstand extreme heat or significant temperature fluctuations. Heat-resistant silicone rubber, for example, can be used in temperatures ranging from -25°C to +250°C. Our HSK wheel series features a tread made of this material.

You should also consider the size and type of load, as well as how it affects the total weight of the vehicle that needs to carry it. For example, different wheels are mounted on a table cart transporting screws compared to an AGV (automated guided vehicle) designed to move large and heavy machine parts.

Once the intended use of the wheel is clear, the load capacity can be determined using the following formula:

- Total weight (weight of the transport device + load) divided by 3 = required load capacity per wheel when using three wheels.

At ambient temperatures between 10°C and 30°C, polypropylene wheels can carry loads of up to 400 kg on smooth surfaces. Wheels made of cast iron can handle up to 1,250 kg, while those made of solid steel can support loads of up to 10,000 kg.

These factors determine the minimum load capacity the wheel must have to ensure safe handling. The method of handling—whether manual or mechanical—and the speed of the vehicle also necessitate different types of wheels.

At TORWEGGE, you will find a wide range of wheels designed to meet diverse requirements.

How and for how long will the wheel be used?

When selecting the bearing, the type and duration of the wheel's usage should be taken into account.

- Plain bearings are simple, largely maintenance-free, and resistant to shocks. They are the most cost-effective and lightweight bearing option but require higher driving forces. Additionally, at high speeds combined with heavy loads, they generate heat more quickly than other types of bearings. Therefore, they are less suitable for continuous use.

- Roller bearings are also maintenance-free but are more robust and durable. They have low rolling resistance and are the most commonly used bearings for devices operating at low speeds.

- Ball bearings are characterized by smooth operation even under higher loads and speeds, making them suitable for continuous use. They are primarily used in technically demanding devices.

How much force can be applied to set the wheel in motion and keep it moving?

When determining how smoothly a wheel should run, the starting and rolling resistance must be assessed. The lower the resistance, the smoother the wheel operates, requiring less force to set it in motion and keep it moving.

Resistance depends on two primary factors: the load capacity and the condition of the surface. For instance, pushing a cart up a slightly inclined path and occasionally crossing cables requires more effort than moving an equally heavy cart on a perfectly level surface with no incline. Additionally, the tire material, bearing type, and wheel diameter influence the level of resistance.

At the time of purchase, the load capacity and surface conditions are already known. The other factors should be selected based on these criteria.

- For wheel diameter, resistance decreases as the wheel size increases. Small wheels suffice when moving a transport device downhill with no obstacles. However, if significant force is needed, such as when navigating uneven surfaces, a larger model is the better choice.

- Regarding tire material, our tests with common materials revealed that polypropylene offers the lowest resistance, followed by polyurethane and thermoplastic rubber.

- Among bearing types, ball bearings provide the smoothest motion, followed by roller bearings and, lastly, plain bearings.

At TORWEGGE, you’ll find a wide range of wheels designed to meet diverse requirements.

Our Diverse Range of Wheels – Start Exploring Now

TORWEGGE offers a comprehensive selection of high-quality wheels for every need. Whether it’s for stage technology, the food industry, or machinery production, our shop has the perfect wheels for every business. Discover the wide variety of premium wheels available in the TORWEGGE online shop today!

Our Wheels in Detail

Wheels need to support various loads and be suited to the specific type of flooring, depending on the requirements. To select the optimal wheel, four key features are crucial: the tire material, the rim, the diameter or wheel width, and the different types of bearings. Below, we provide an overview of our extensive range.

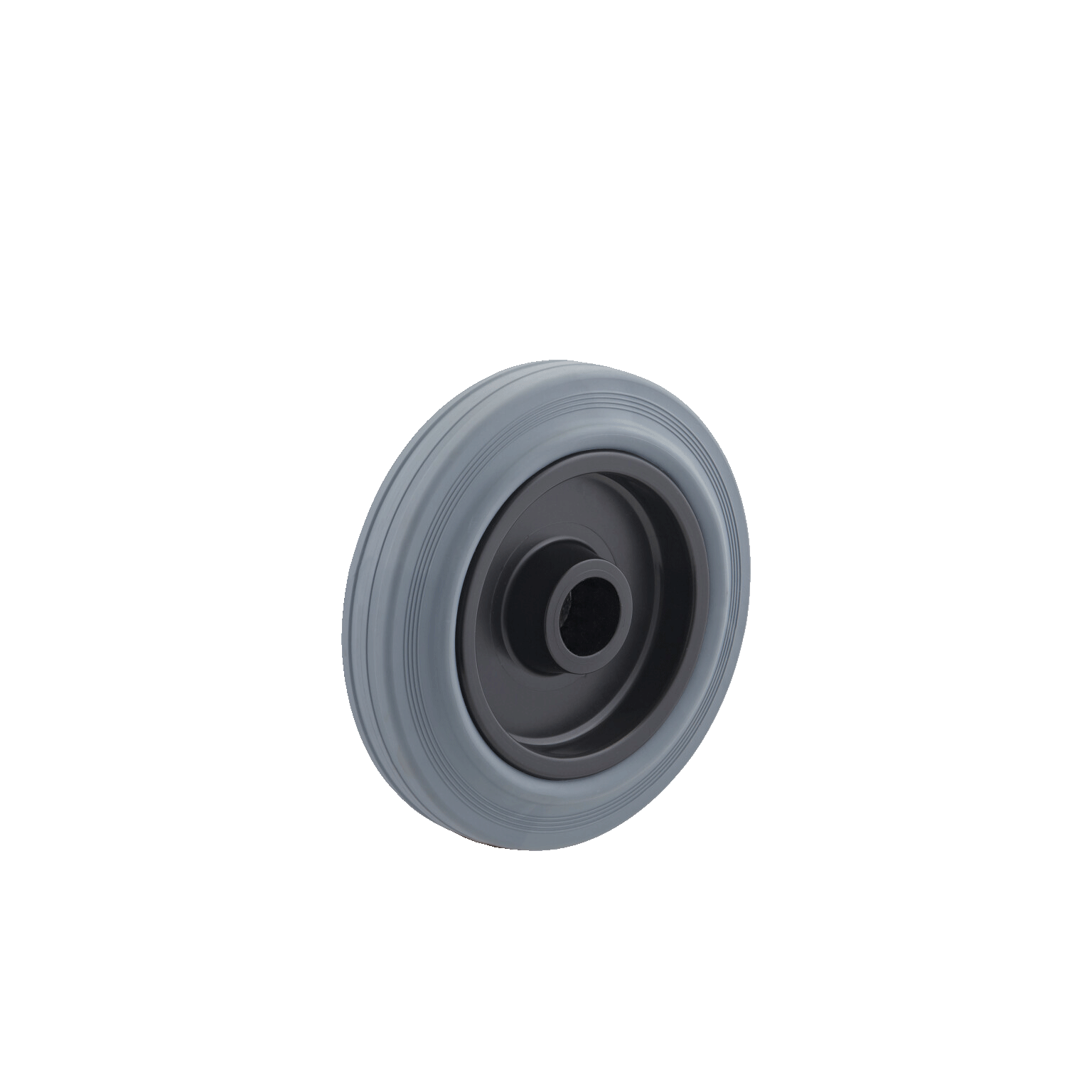

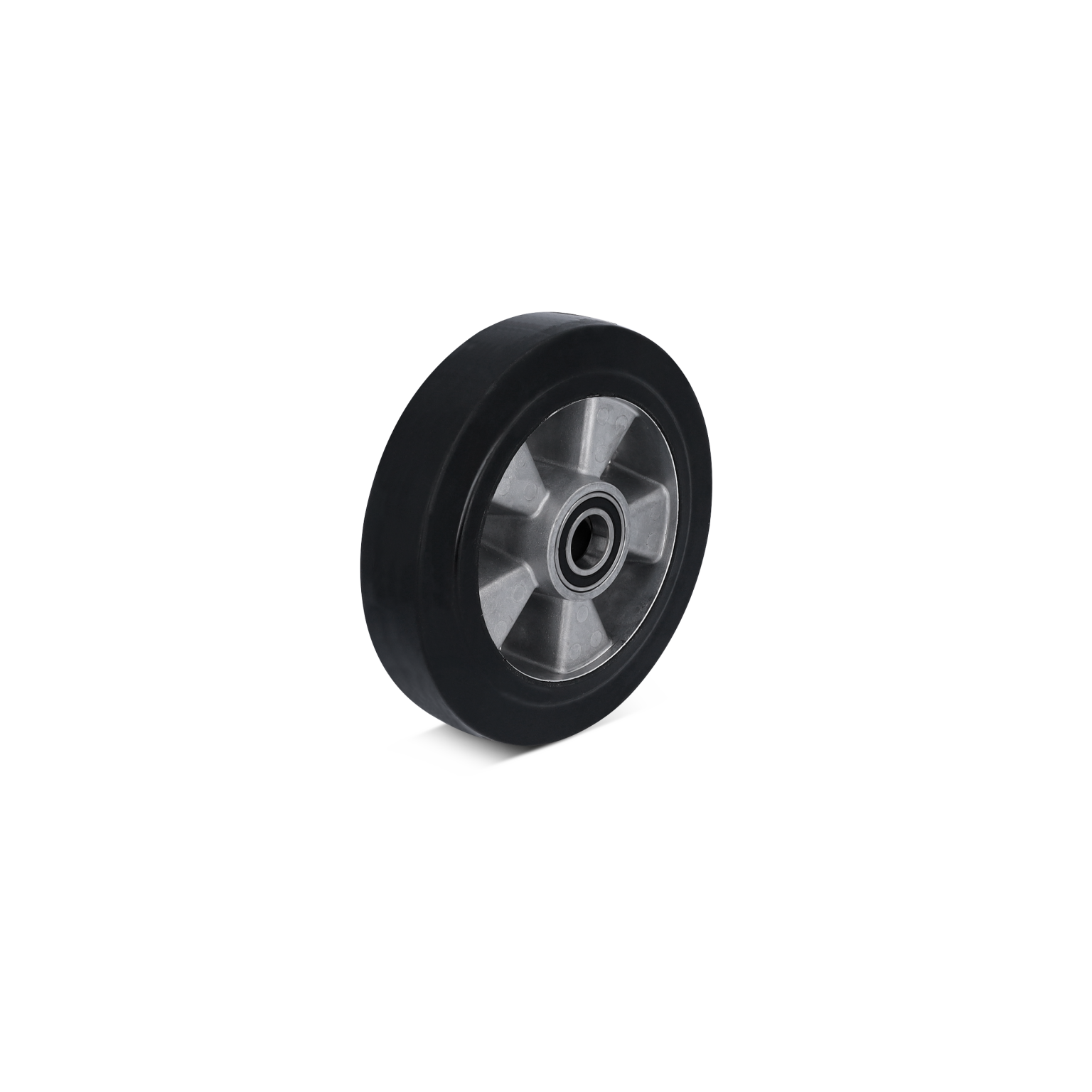

Buy Solid Rubber Wheels

Depending on the application, our affordable TORWEGGE solid rubber wheels are suitable for both light and heavy-duty uses and can be employed in a variety of indoor and outdoor settings.

Solid Rubber: is the classic choice among treads and is used in many industrial applications. Wheels made from this material are cost-effective and offer a wide variety of options. They provide good rolling comfort, run quietly, and are gentle on floors. However, they have a relatively high rolling resistance and only the grey variants are non-marking.

If you're looking for wheels that protect your goods from shocks and vibrations, consider our elastic solid rubber wheels.

Elastic Solid Rubber: offers greater driving comfort compared to standard solid rubber. As the material is softer, these wheels better absorb vibrations and impacts. They also have a higher load capacity, making them ideal for use in sound systems or stage technology.

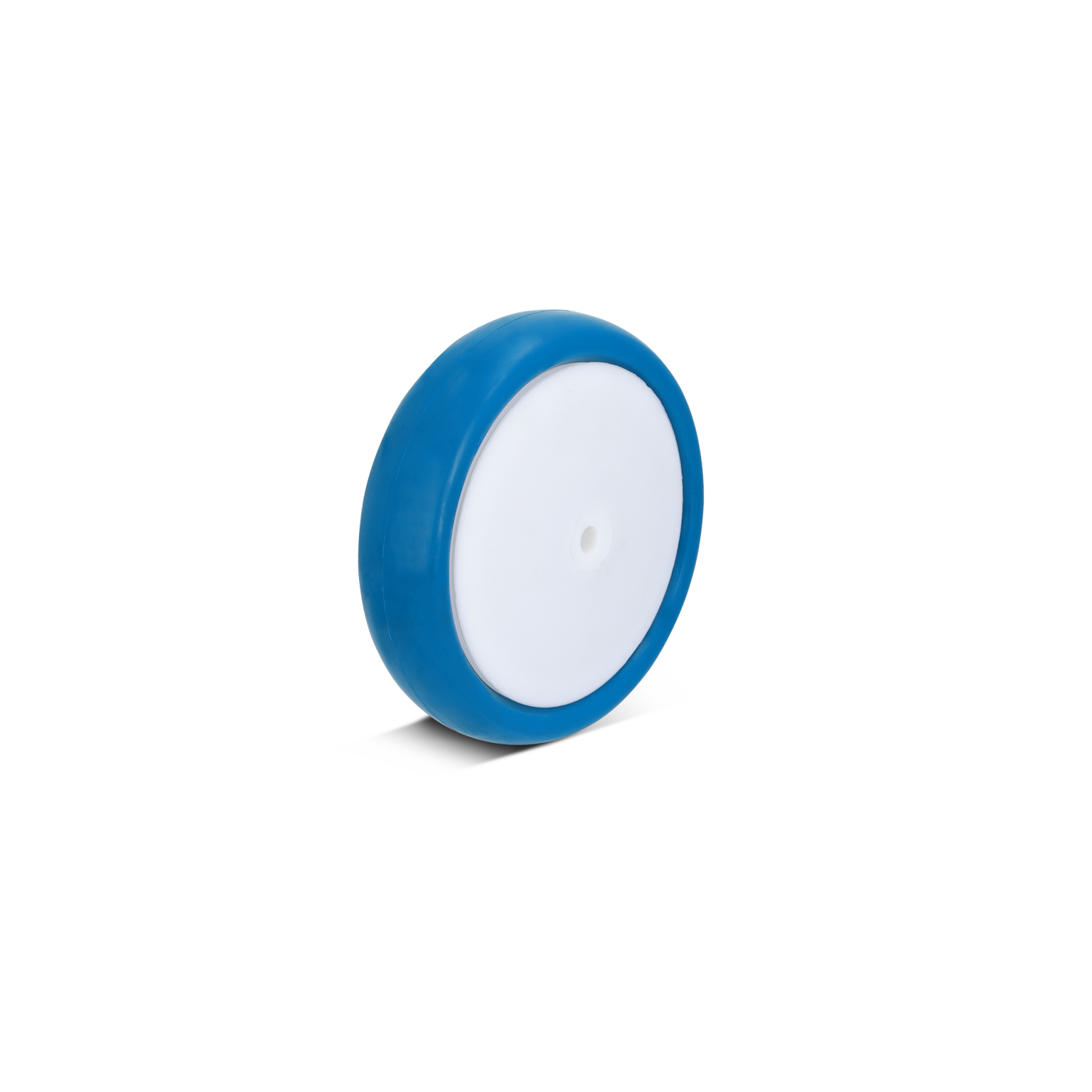

Buy Thermoplastic Wheels

Thermoplastic wheels are a smart alternative to standard solid rubber wheels and just as versatile in their applications. Similarly priced, thermoplastic wheels are smoother-running, non-marking, and free from health-hazardous PAHs (polycyclic aromatic hydrocarbons). This makes them suitable for use in products like children's toys. In addition to their health benefits, thermoplastic wheels offer improved rolling performance, are completely non-marking, and are odorless.

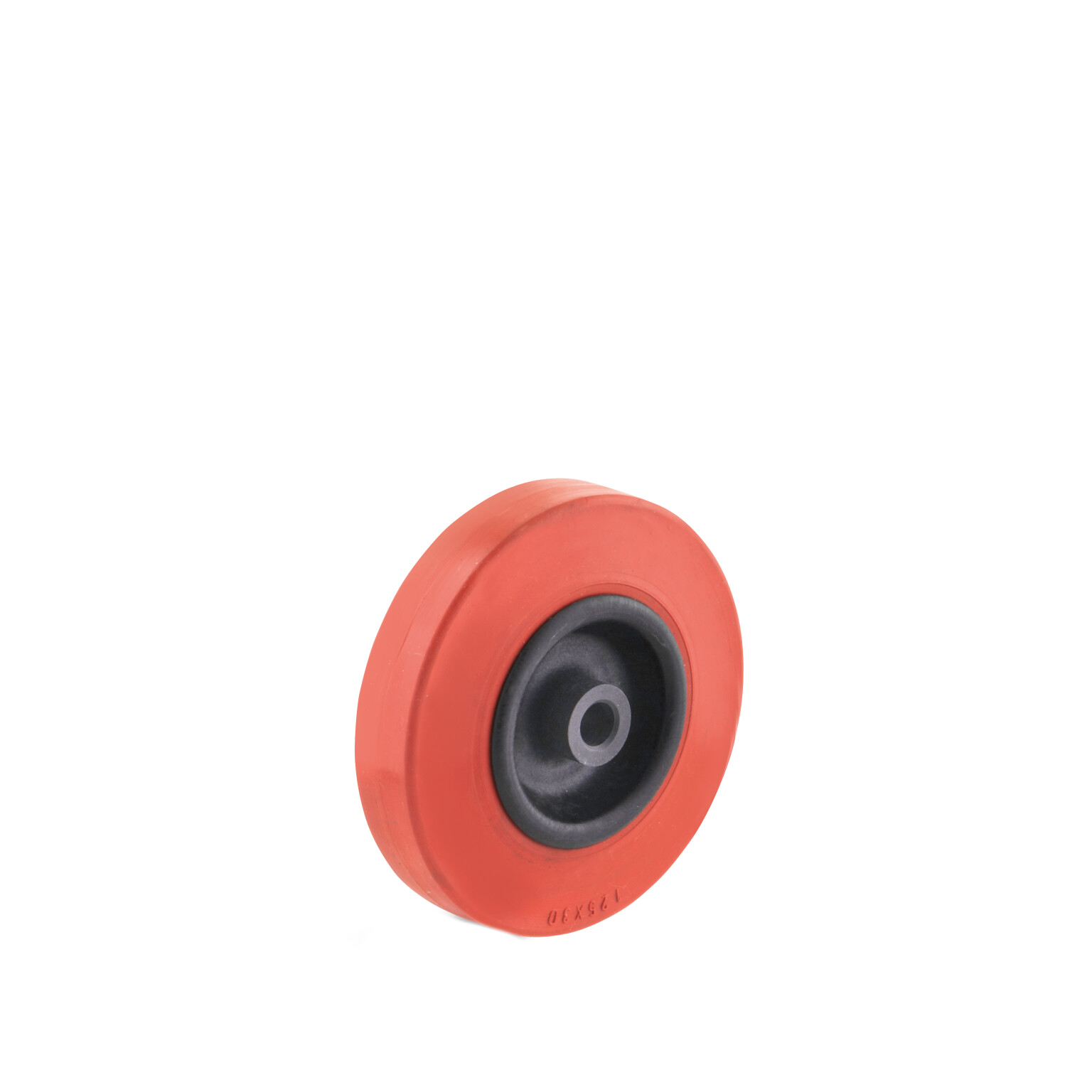

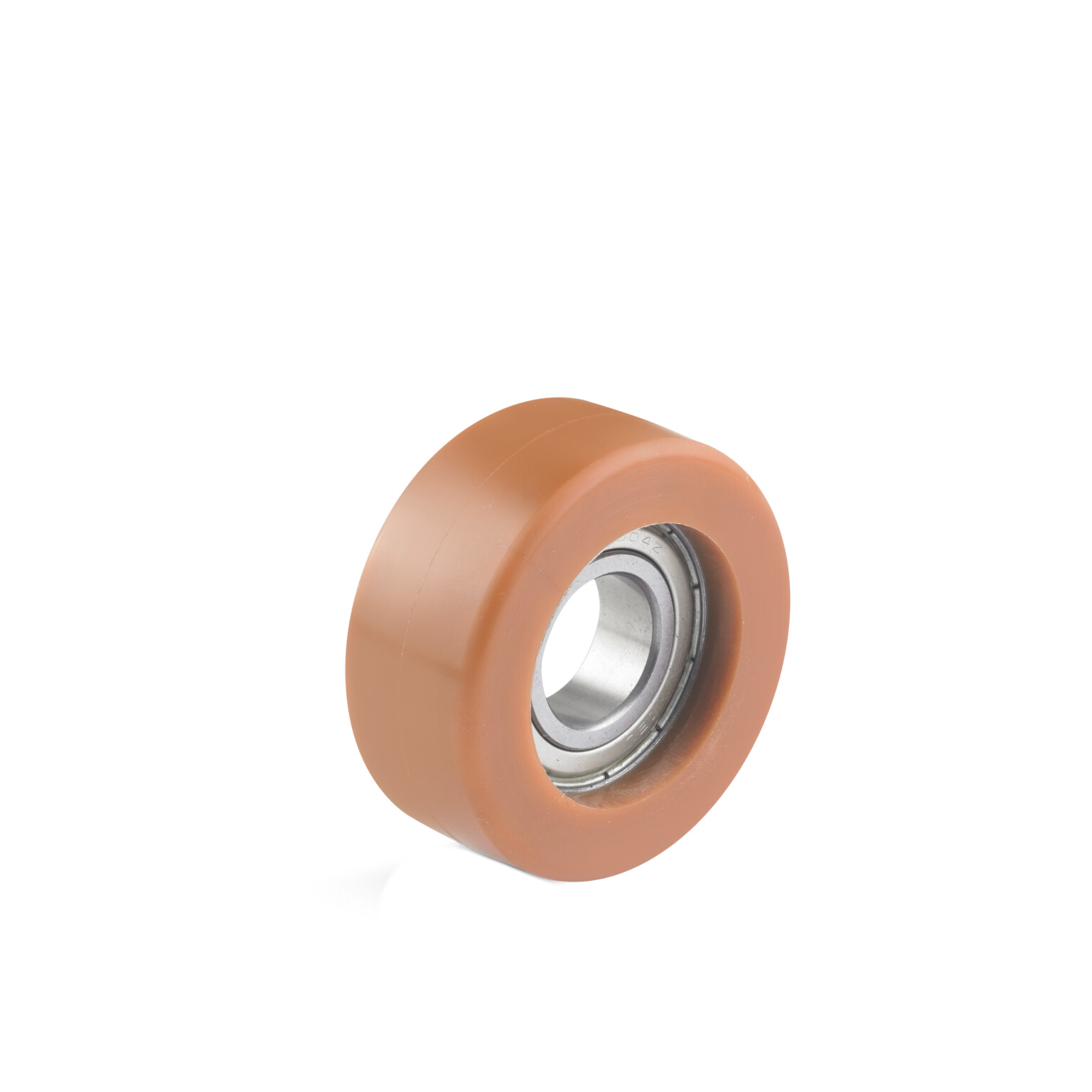

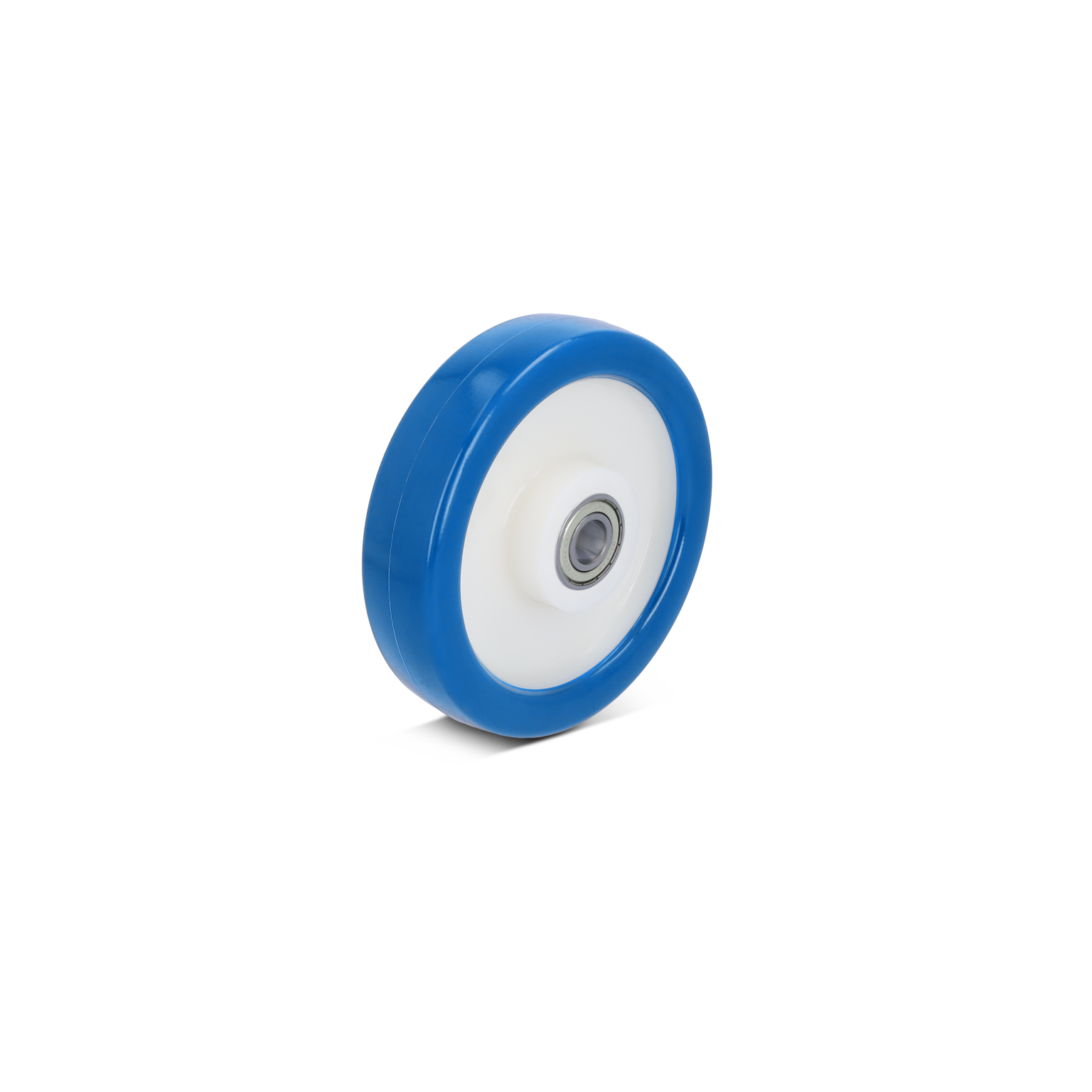

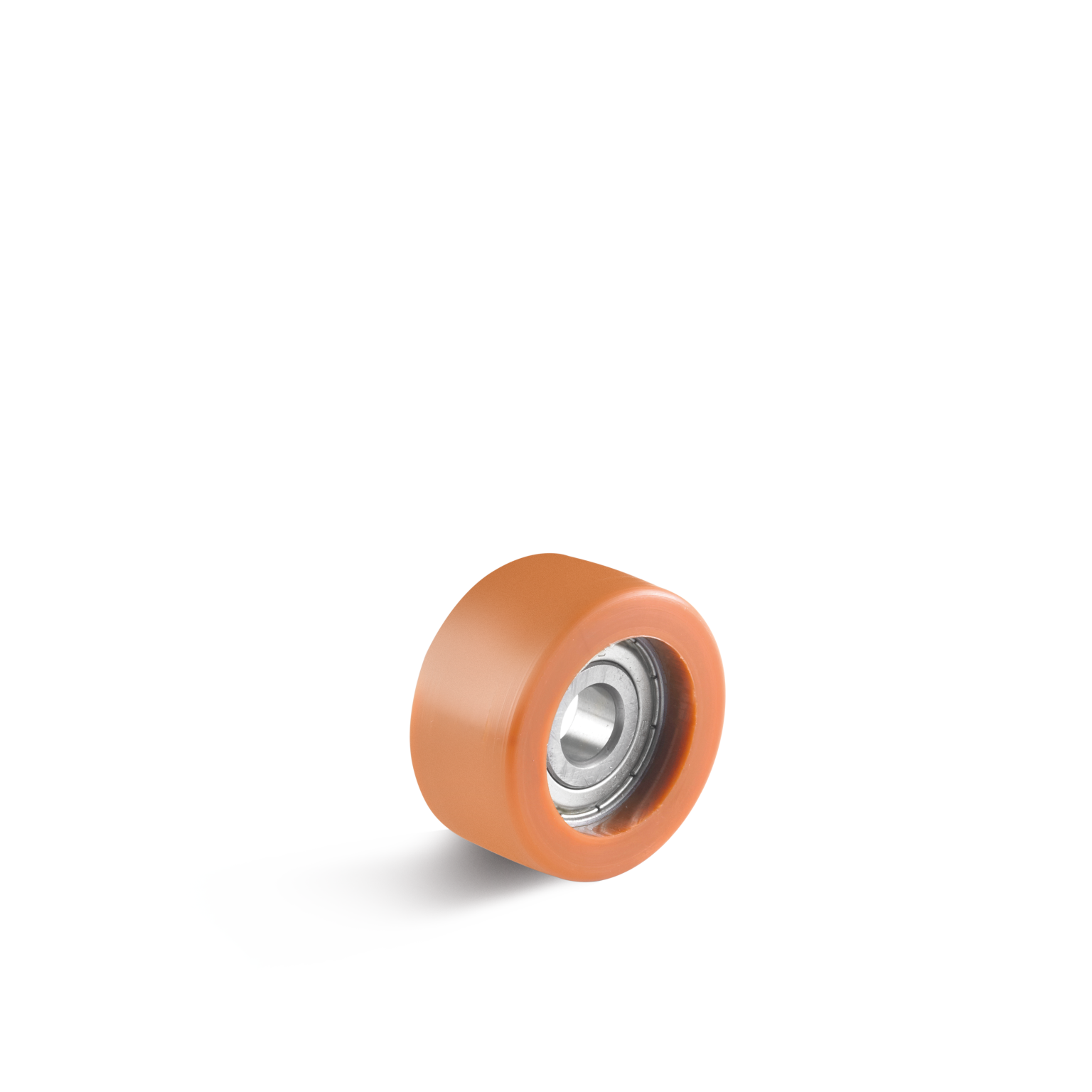

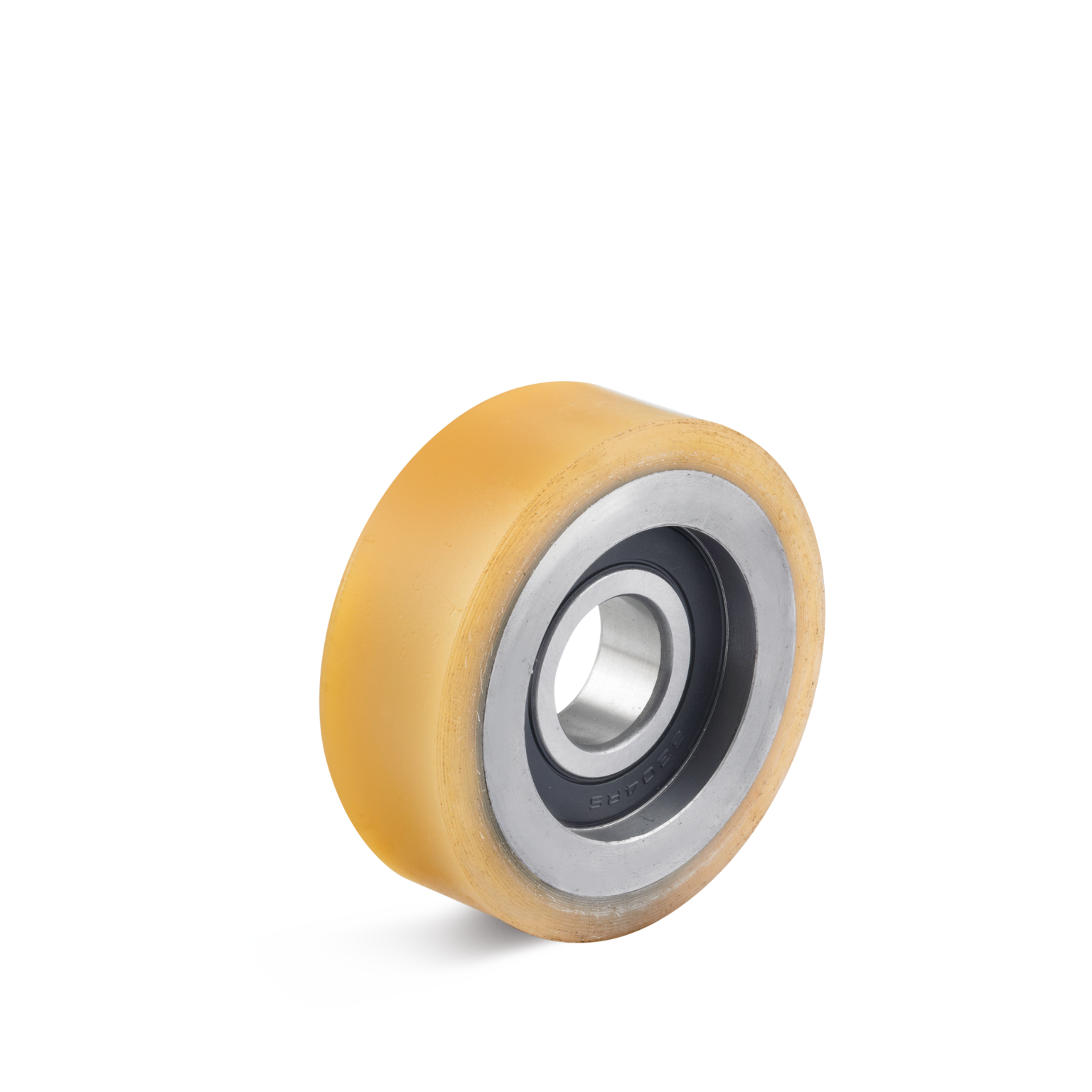

Buy Polyurethane Wheels

Polyurethane wheels are durable, robust, and smooth-running, making them suitable for use on various surfaces, from light to heavy-duty applications. They are available in two variants: polyurethane and elastic polyurethane.

Polyurethane: Wheels made from this material are the ultimate all-rounder for industrial use. They combine the elastic properties of rubber or thermoplastic wheels with the high load capacity and low rolling resistance of plastic wheels. Additionally, they are cut-resistant against metal shavings and resistant to oil and grease.

Elastic Polyurethane: This softer material reduces load capacity but absorbs shocks more effectively, providing superior ride comfort. Elastic polyurethane wheels are ideal for applications requiring maximum comfort and vibration dampening.

Buy Pneumatic and Puncture-Proof Wheels

Pneumatic wheels are air-filled rubber wheels that provide exceptional ride comfort, especially on uneven and loose surfaces. Our pneumatic wheels are available in a variety of designs and tread types. They differ in wheel diameter, tread patterns, wheel bodies, and tire thicknesses. Thanks to their excellent vibration-damping properties, they are suitable not only for industrial applications but also for transporting delicate goods. For loads up to 200 kilograms, foam-filled polyurethane wheels offer a puncture-proof alternative.

We also supply puncture-proof wheels with air-like performance. The most well-known application for pneumatic wheels is, of course, the automobile.

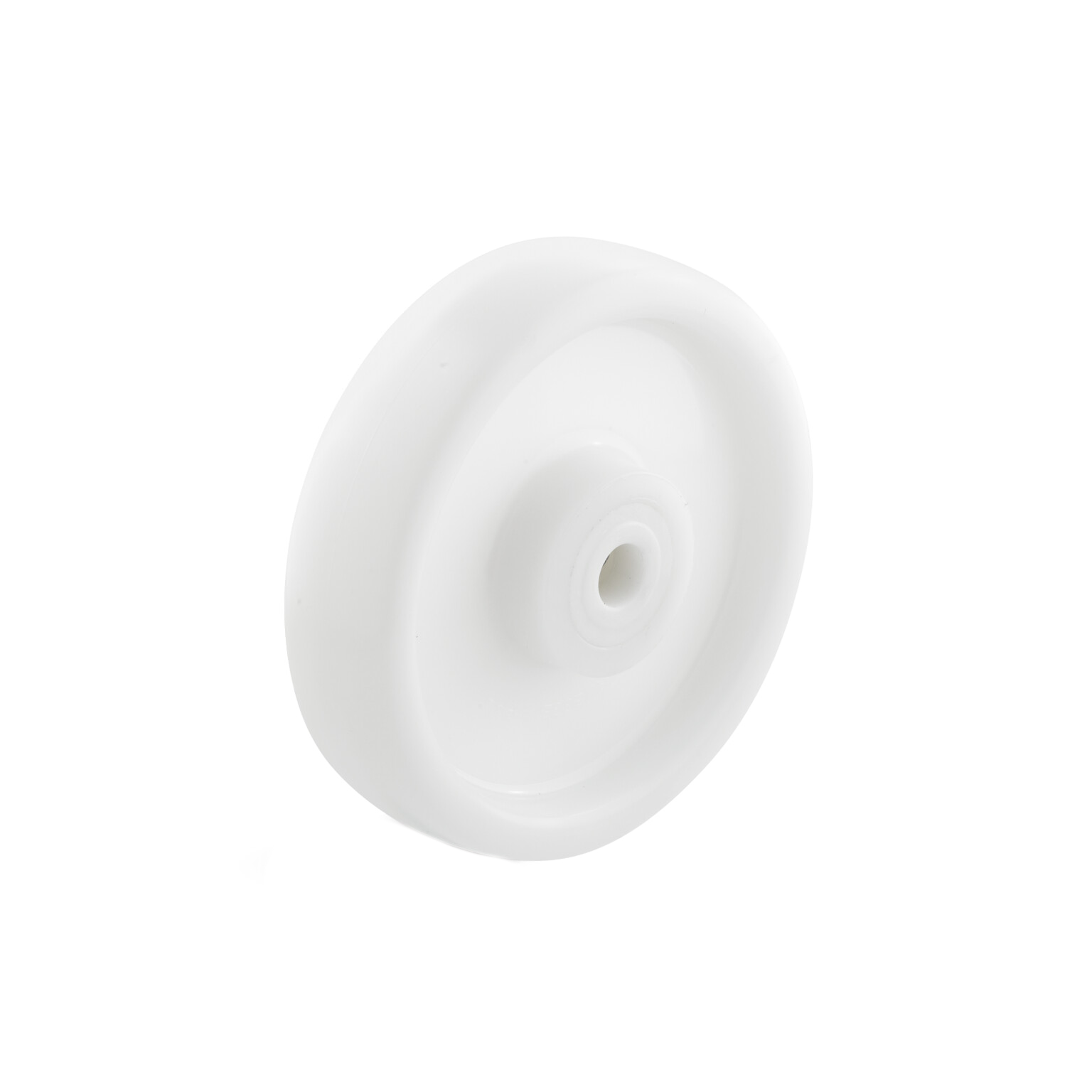

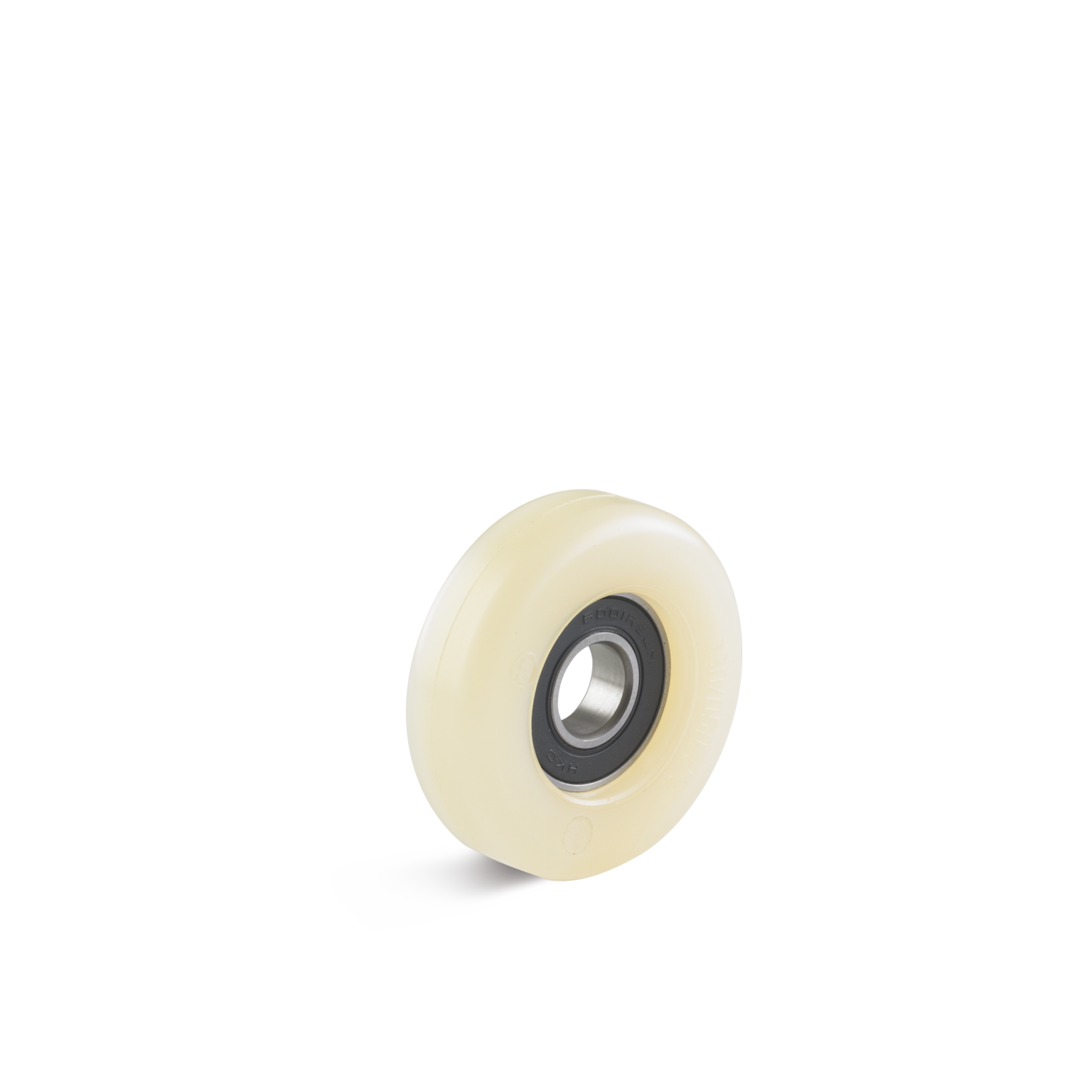

Buy Plastic Wheels

Plastic wheels made of polypropylene or polyamide are ideal for smooth, even surfaces and are particularly easy-running. They offer the lowest rolling resistance and high chemical resistance.

Polypropylene: Wheels made from this material are highly maneuverable and extremely durable. They are resistant to acids and alkalis and can support loads of up to 700 kilograms.

Polyamide: Polyamide wheels are also highly maneuverable and robust. Additionally, polyamide is shatterproof, and wheels made from this material can carry loads of up to 6 tons.

In general, plastic wheels are perfect for use on smooth floors due to their exceptional maneuverability and ease of movement. However, they do not provide vibration damping.

Buy Wheels with Stainless Steel Ball Bearings

Wheels with stainless steel ball bearings are particularly corrosion-resistant. Their quiet operation and low rolling resistance make them an excellent choice for use in industrial and production facilities.

Buy ESD Wheels

For applications requiring specific static properties, our ESD wheels are the ideal solution. These wheels discharge electrical charges generated by friction, allowing safe transport of highly sensitive equipment. This is especially critical in fields like medical technology.

Buy Heat-Resistant Wheels

If wheels are exposed to very high or low temperatures, we recommend our heat-resistant wheels. These are highly durable against extreme temperature fluctuations, making them suitable for applications such as the food industry.

When wheels are exposed to low temperatures for extended periods, bearing friction increases. Additionally, load capacity and stability decrease under the influence of cold or heat. High temperatures, on the other hand, significantly reduce the load-bearing capacity and lifespan of the treads, limiting functionality and shortening service life.

Specially blended solid rubber and plastic materials are excellent choices for handling temperature variations. Wheels regularly exposed to heat, such as in medical technology or the food industry, should be made from heat-resistant materials like polyamide or phenolic resin. For extremely low temperatures, materials such as polyurethane elastomers are ideal, as they remain elastic and flexible even at temperatures as low as -30°C.

Buy Heavy-Duty Wheels

Heavy-duty wheels made of cast iron or steel offer high load capacity and exceptional temperature resistance. These features enable the transport of goods weighing up to 10 tons on solid floors.

Even under extreme conditions, heavy-duty wheels perform reliably. Depending on the design, they can be used in temperature ranges from -100°C to +600°C. Cast iron heavy-duty wheels also offer high tensile strength and chemical resistance.

Buy Flanged Wheels

Flanged wheels are used when rails guide the transport path along a defined line. These wheels can be integrated into the rails and are primarily used in rail vehicles or industrial facilities.

Buy Drive Wheels

Motorized vehicles require drive wheels to convert engine power into motion. Commonly used in forklifts or floor vehicles, these wheels are characterized by their high load capacity.

Electrical Wheels

A distinction is made between electrically conductive and non-conductive wheels—and for good reason. Conductivity protects against electrostatic discharge, which can be generated by transport devices or the goods being transported.

In industries such as pharmaceuticals, medicine, or automotive manufacturing, the electrical conductivity of wheels plays a significant role. Non-conductive wheels accumulate static electricity through friction, leading to an undesirable effect: the charge cannot dissipate, and the next grounded contact causes a sudden discharge. In some operations, this poses a considerable risk.

When wheels come into contact with chemicals, it is crucial—just as mentioned earlier—to consider chemical resistance during selection. Materials such as stainless steel, thermoplastic rubber, and certain plastics offer excellent chemical resistance.

What Are Colored Wheels Used For?

- Orientation: Colors can be used to group wheels and assign specific functions. For example, grey-treaded wheels may be designated for outdoor use, while yellow ones are for indoor use. Similarly, transport devices with red wheels might be intended for goods weighing over 200 kg, while those with green wheels are designed for lighter loads.

- Efficiency: Colored wheels can act as coding systems. For instance, which department does a transport device belong to? Are the items on it already cleaned, or do they still need cleaning? Is the device suitable for hot environments? In companies using clear color codes, such questions can be answered at a glance by looking at the wheels. This saves time and reduces errors.

- Visibility: Typically, wheel treads are white, grey, or black, which are harder to spot on neutral floors. If a wheel, for example, is positioned sideways to the chassis it's attached to, it can become a tripping hazard. Colored wheels can help reduce this risk by making them more noticeable.

- Safety: Improved visibility enhances workplace safety. Colored indicators, such as red for "the brake is engaged" or green for "the brake is released," further contribute to a safer working environment.

- Recognition/Identification: Colored wheels can align better with a company's corporate design than standard white, grey, black, or blue wheels. Purchasing wheels in corporate colors is not purely for aesthetic reasons. Internally, it fosters employee identification with the company through a unified appearance. Externally, it increases brand recognition and often conveys a more professional image.

We can manufacture nearly all treads in any RAL color. Whether the wheels should feature colored markings or be entirely colored is entirely up to our customers. Upon request, we produce wheels and castors in alignment with the corporate design specifications of our clients.

Customer preferences regarding the color of wheels and castors are not limited to the treads. Other components can also be colored. For instance, markings on brakes can indicate whether the castors are locked (red) or unlocked (green).

Whether you already have specific color ideas or need advice on the right color scheme, we’re here to help. Feel free to contact us!

Buy Wheels at TORWEGGE Now

Are you looking for the perfect solution to move your goods with ease? Visit our shop and order high-quality TORWEGGE wheels for every application at affordable prices online. Discover a wide range of wheels and castors, including guide rollers or solid rubber wheels. In addition to premium wheels and accessories, you’ll find many other useful transport solutions and products in the field of conveying and handling technology. With TORWEGGE’s range, you can streamline numerous workflows in your company, reduce strain on your employees, and save resources. If you can’t find the right part, don’t hesitate to contact us. We’ll be happy to advise you on our TORWEGGE wheels and assist you personally in finding the ideal solution for your business. We provide customized solutions of the highest quality standards—fast, innovative, and competitively priced. Rely on TORWEGGE’s years of experience in conveying and transport technology.

If you’re also interested in our conveying technology, feel free to explore this category as well. It includes everything from conveyor rollers to load wheels.