High-Quality Rope Pulleys for Heavy Loads

Rope pulleys are essential components for projects requiring the lifting of heavy loads with wire ropes. In crane construction or logistics, reliable rope pulleys are among the most crucial pieces of equipment. Acting as steering elements for high tensile forces during the redistribution of loads, they endure significant tension as well as friction. Explore TORWEGGE's range of meticulously crafted and durable rope pulleys today!

40 mm

12 mm

35 kg

98 mm

20 mm

150 kg

140 mm

26 mm

135 kg

120 mm

26 mm

140 kg

40 mm

11 mm

85 kg

Shift Your Weights with Smart Pulley Technology

The pulley system for lifting loads was discovered centuries ago and used as early as ancient Greece to construct some of the most remarkable structures of human civilization. Despite the technological advancements made since then, the fundamental principles of mechanics have remained the same. We still rely on intelligent redirecting pulleys to change the direction of weight forces. However, the designs, materials, and specifications of rope pulleys have become much more diverse and now offer a range of unique features. There are also various mounting options, such as the swivel-mounted bird pulley that hangs from the ceiling or a fixed installation in a pulley block secured to the floor or wall. Selecting the right product depends on the intended application of the rope pulley.

Advantages of Rope Pulleys

The use of rope pulleys offers a variety of benefits across different applications. They enable the redirection of ropes or cables, allowing them to navigate around corners or obstacles. This makes it possible to use ropes and cables in areas where straight-line movement is not feasible. Rope pulleys help manage tension in the rope, which is particularly important in applications such as lifting devices, cranes, and elevators. By evenly distributing the load across the rope, they ensure the safety and efficiency of these systems. Additionally, rope pulleys reduce friction and wear on the rope or cable by guiding it over smooth surfaces. This extends the lifespan of the rope and minimizes maintenance requirements. Another key advantage is their ability to evenly distribute stress along the rope or cable, preventing excessive strain or localized wear. This enhances the safety and reliability of the application. Rope pulleys also allow ropes and cables to move in various angles and directions, increasing the flexibility and versatility of their use. In outdoor and recreational activities such as climbing or ziplining, they facilitate the safe movement and transport of people or equipment. In industrial and commercial applications, they improve the efficiency of lifting and hauling systems by enabling precise and controlled movement of loads.

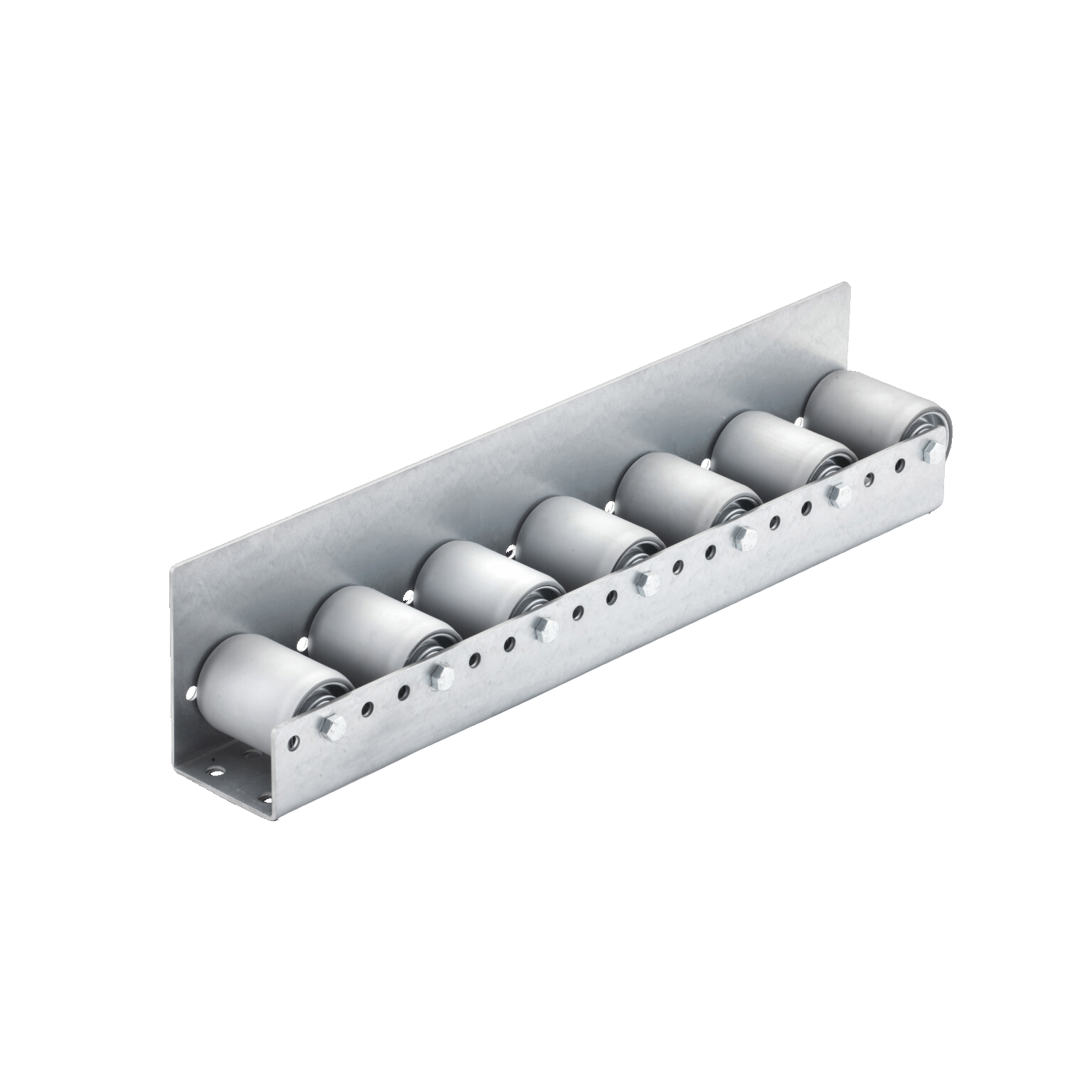

Wear Reduction Through the Proper Selection of Rope Pulleys

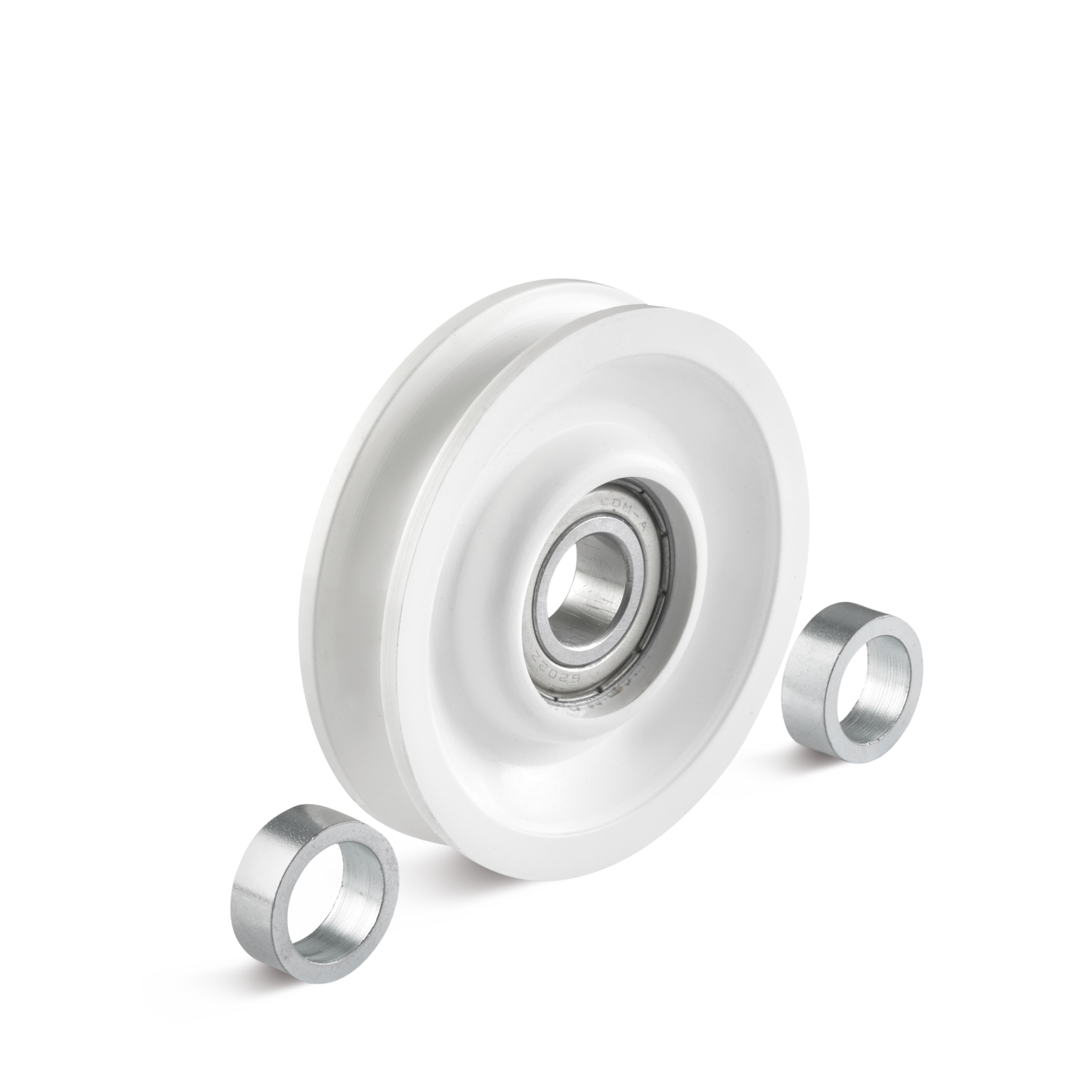

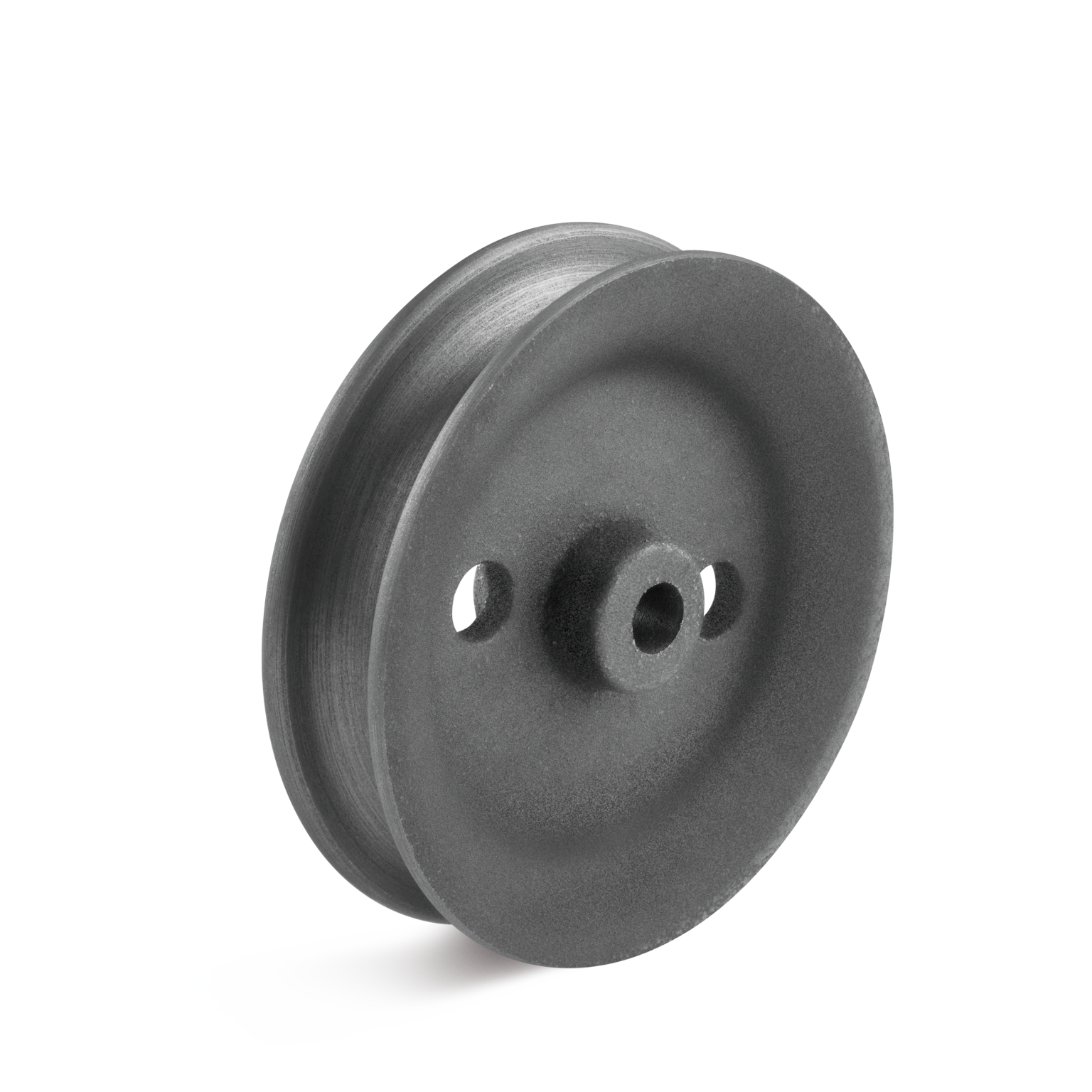

The type of rope pulley your operation requires primarily depends on the weight of the loads being handled. For heavy loads, it is essential to choose a highly durable pulley with low rolling resistance. The most robust bearing type for rope pulleys is the roller bearing, which should be prioritized for particularly high tensile forces, followed by the widely used ball bearings. To ensure a long service life for ball and roller bearings, frequent lubrication and sealing against moisture and dirt are indispensable. For lighter loads or environments with liquid lubrication, pulleys with plain bearings are a cost-effective and low-maintenance alternative. These pulleys are highly durable and resistant, making them ideal for such applications.

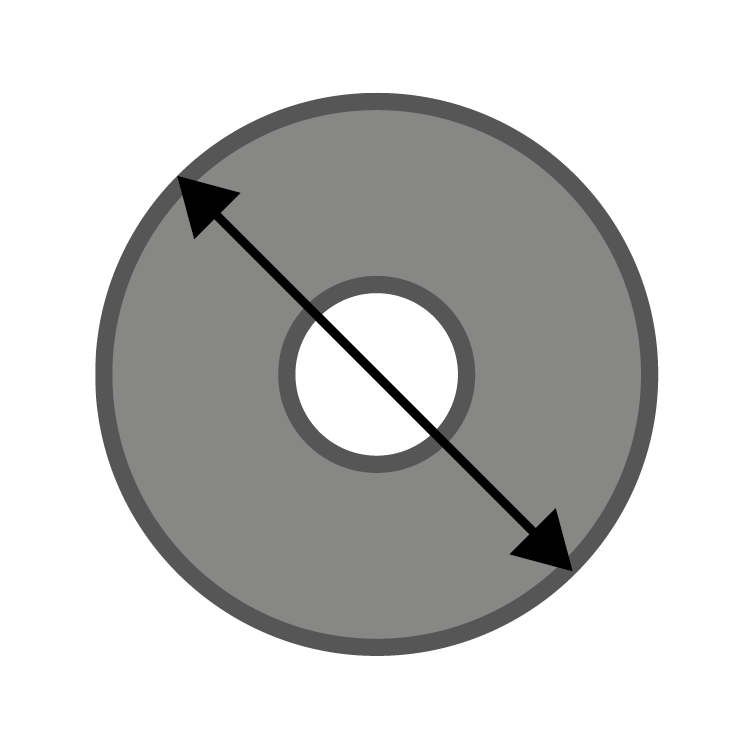

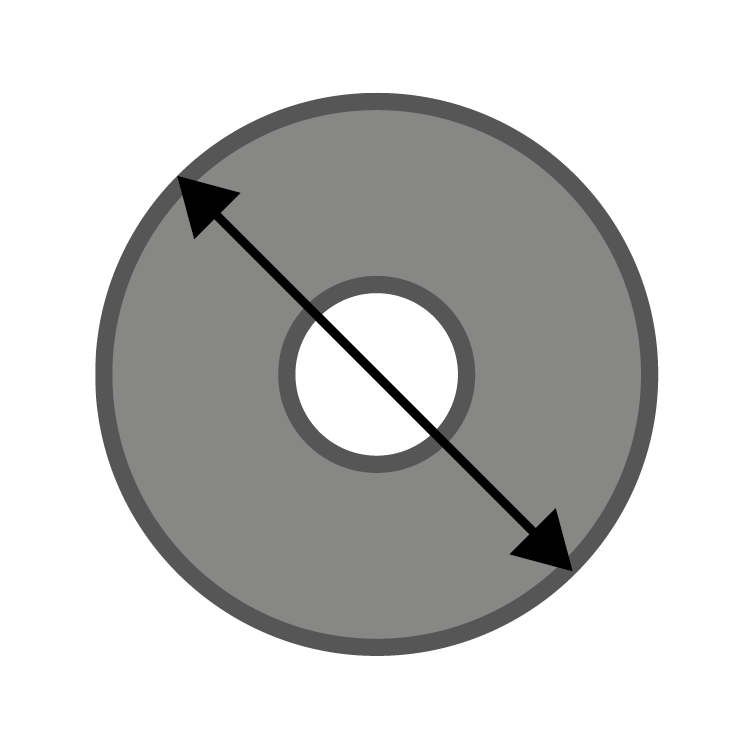

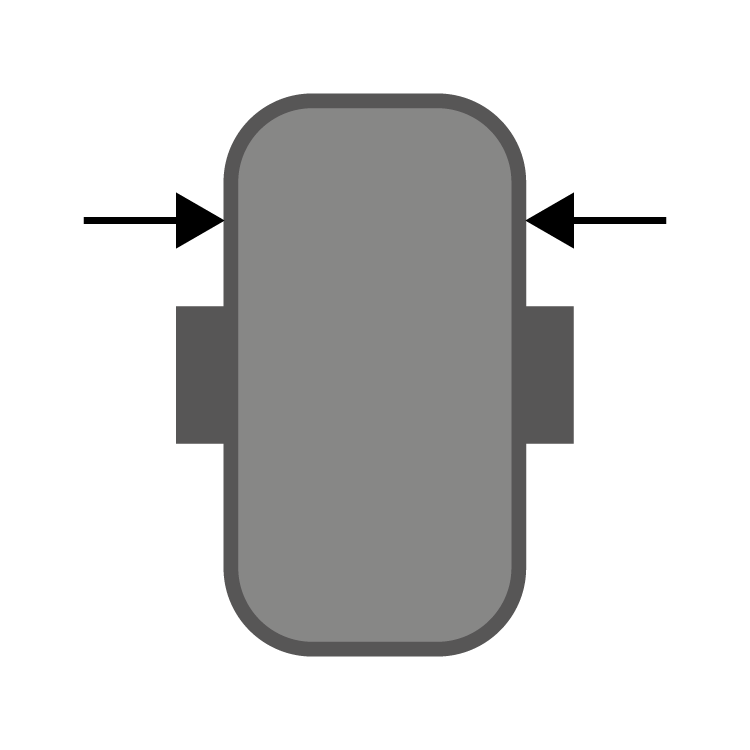

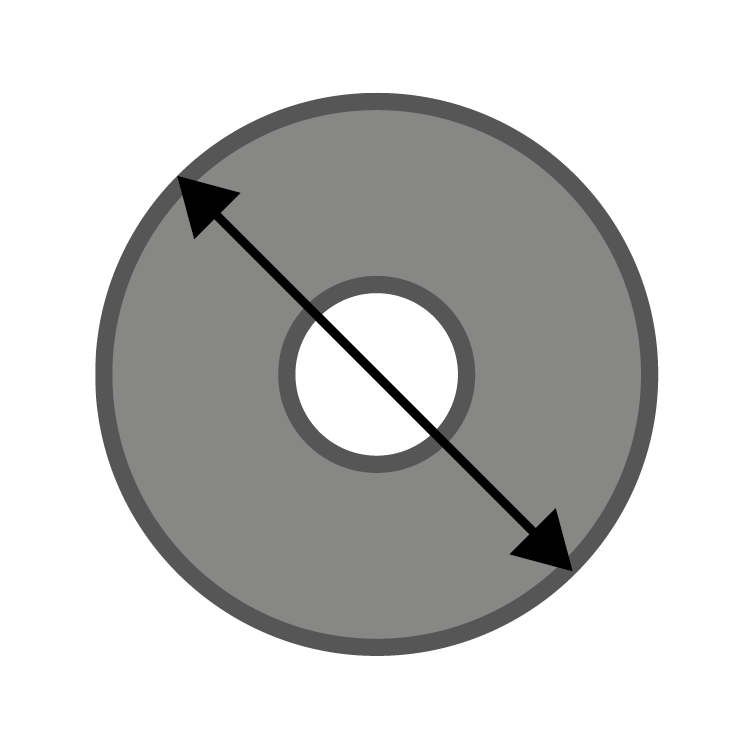

Equally important is carefully calculating the dimensions of your rope pulleys to minimize rope wear caused by bending fatigue. Factors such as the width and shape of the groove and the pulley radius should be considered. Depending on the intended use, the pulley can be made from various materials. For instance, if it is a swivel-mounted pulley, a lightweight material is recommended to reduce its own inertia. However, the required load capacity must always take precedence.

Order Durable Rope Pulleys in Our TORWEGGE Online Shop!

Our online shop offers high-quality rope pulleys that you can conveniently compare using our comparison tool or the filter options in the sidebar. Our range includes pulleys with plain bearings, roller bearings, and ball bearings. We manufacture our rope pulleys according to strict quality standards using materials such as polyamide, gray cast iron, or steel. For any questions or concerns, feel free to reach out to our team at any time! Additionally, take a look at our selection of wheels, solid rubber wheels, track rollers, and pressure rollers.