Solid Rubber Wheels

Wheels and castors are practical helpers both at home and at work and are always with us. They make it easy to move and manoeuvre goods and merchandise. With the right wheels and castors, you can efficiently relieve the strain on yourself and your employees and thus create more flexibility in your company.

Whether in the field of stage technology, in the manufacture of machinery or in sensitive areas such as food processing, where strict hygiene regulations apply - there are numerous scenarios in which a variety of castors and wheels are required. TORWEGGE therefore provides its customers with a versatile range of castors and wheels that fulfil all requirements. Our range extends from gentle solid rubber tyres to wheels with special heat resistance and electrically conductive castors. In this way, we present you with a diverse selection of suitable products with different properties that are relevant for various areas of application. Discover the right wheels and castors to meet your specific requirements in the TORWEGGE online shop.

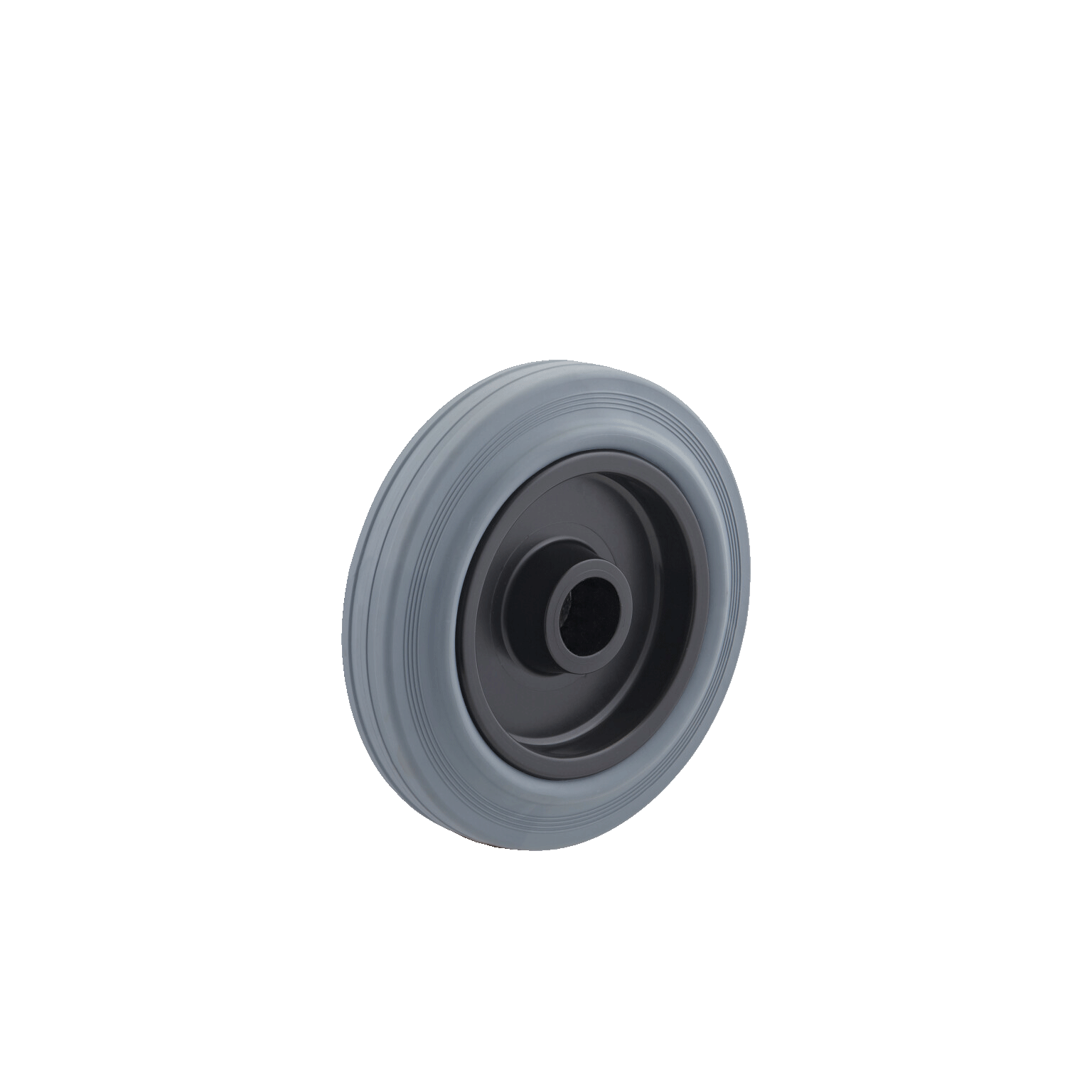

Solid Rubber Wheels

Thermoplastic Wheels

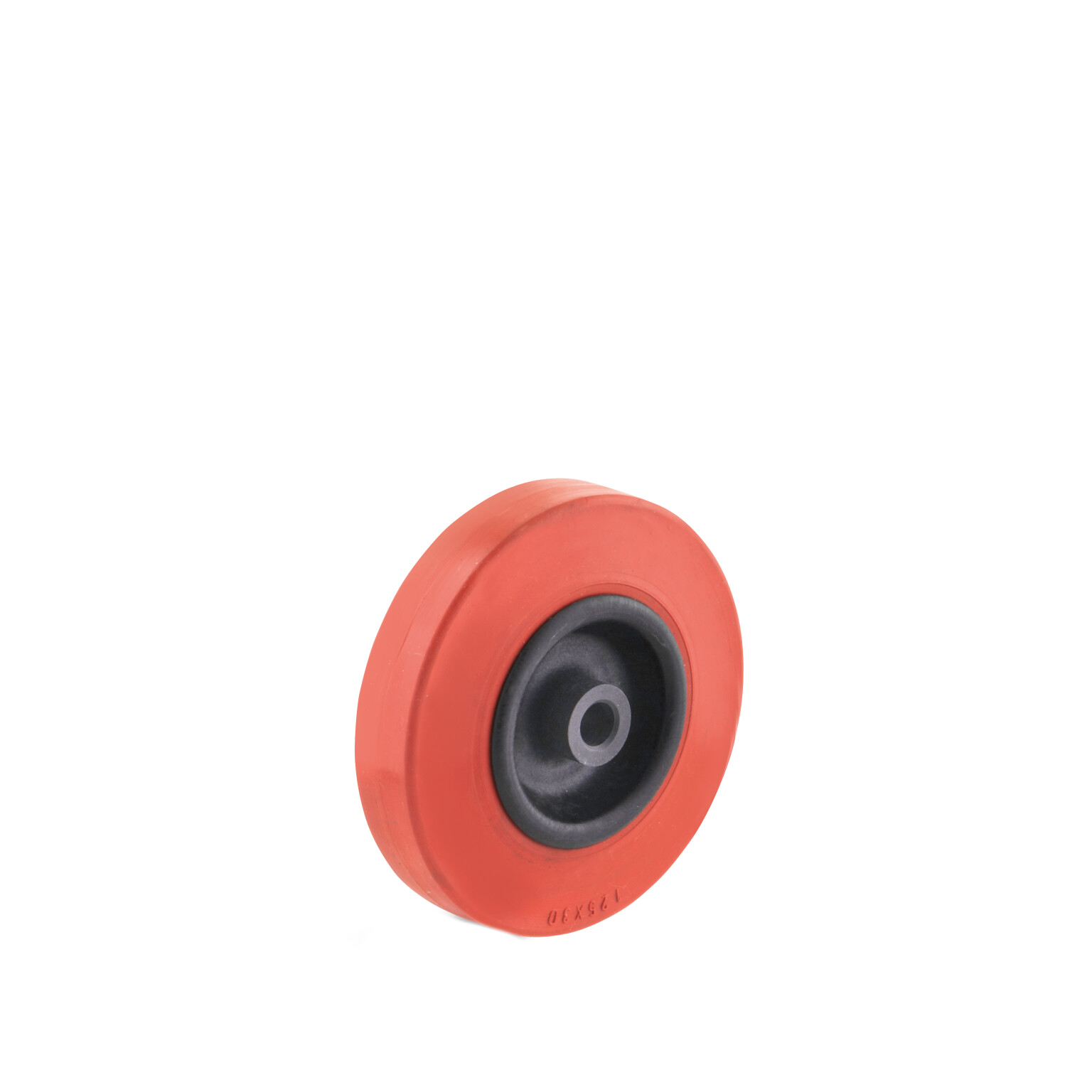

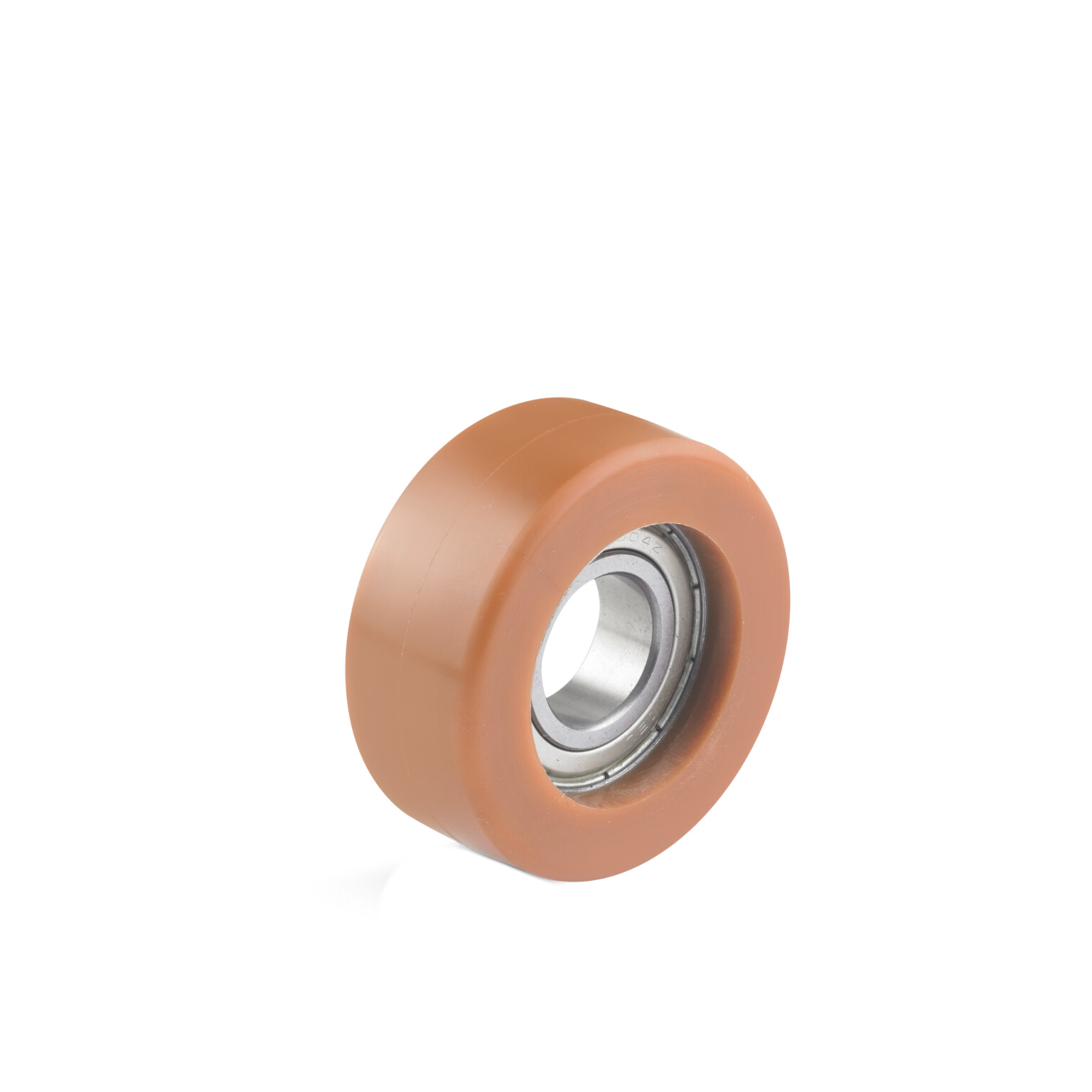

Polyurethane Wheels

Air Wheels and Puncture-Proof Wheels

Plastic Wheels

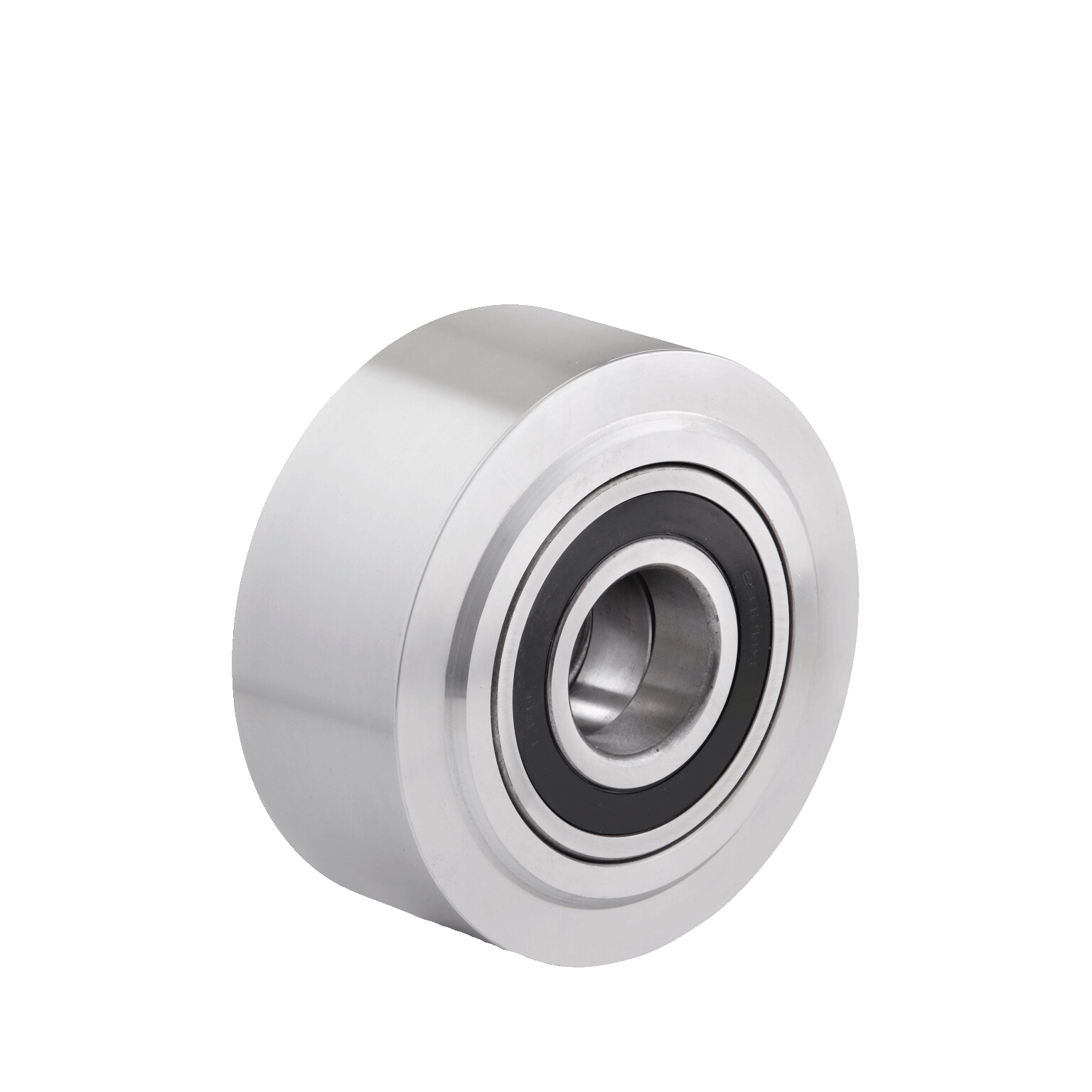

Wheels with Stainless Steel Ball Bearings

ESD Wheels

Heat-Resistant Wheels

Heavy-Duty Wheels

Guide Rollers

Door Rollers

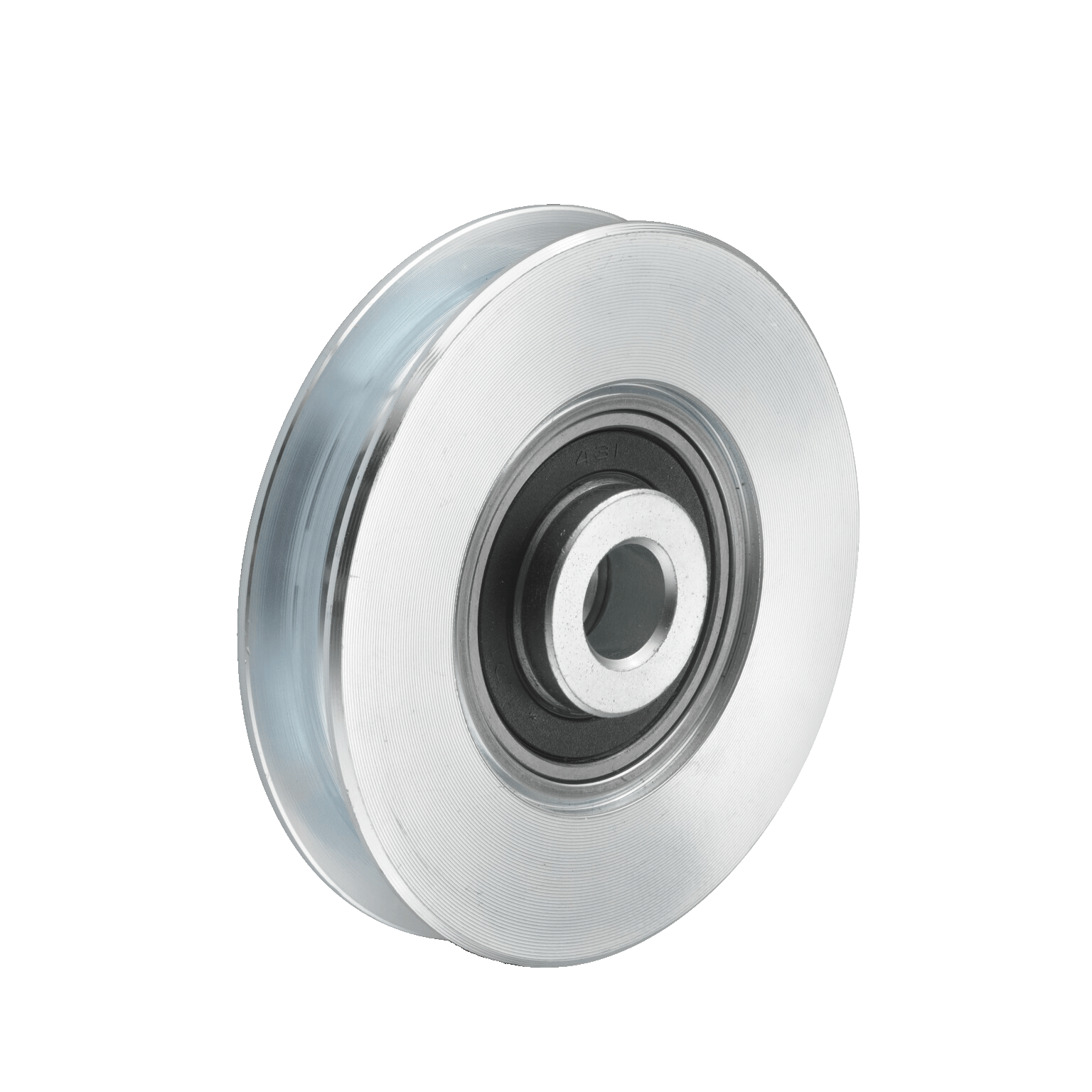

Track Rollers

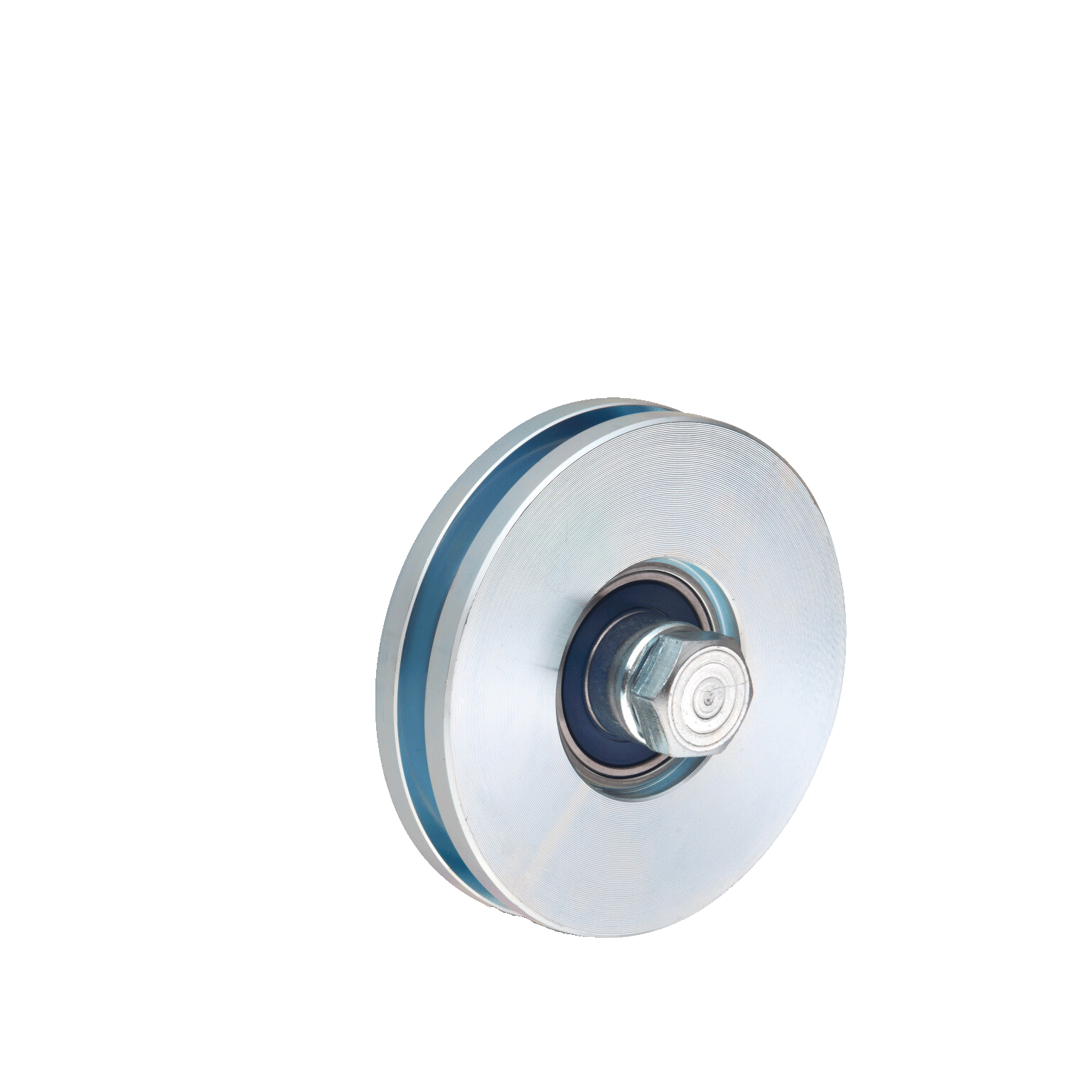

Rope Pulleys

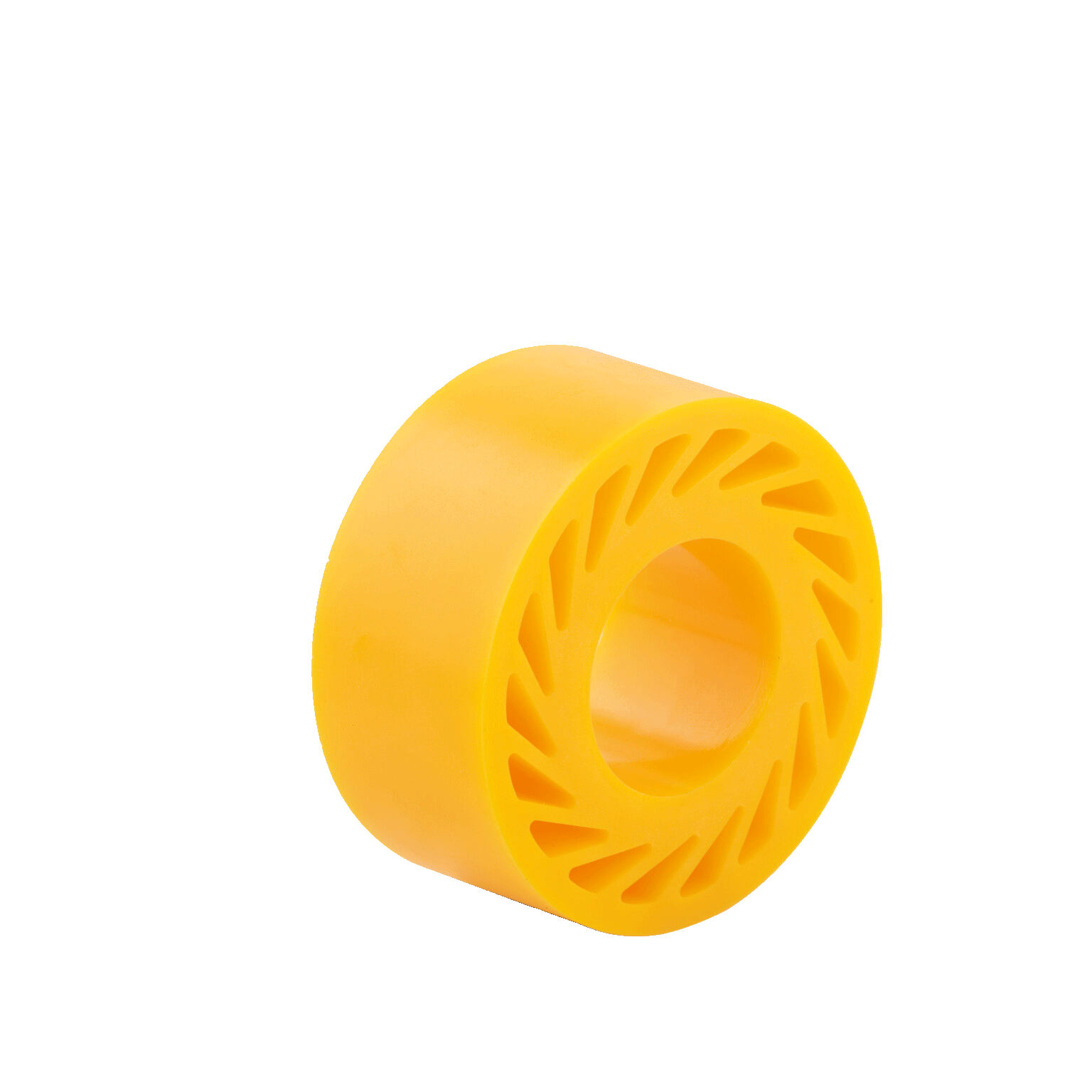

Pressure Rollers

Flange Wheels

Pallet Truck Rollers

Drive Wheels

Bands

Apparatus Castors

Furniture Castors

Blue Wheel Castors

Swivel and Fixed Castors up to 450 kg

Swivel and Fixed Castors up to 1,250 kg

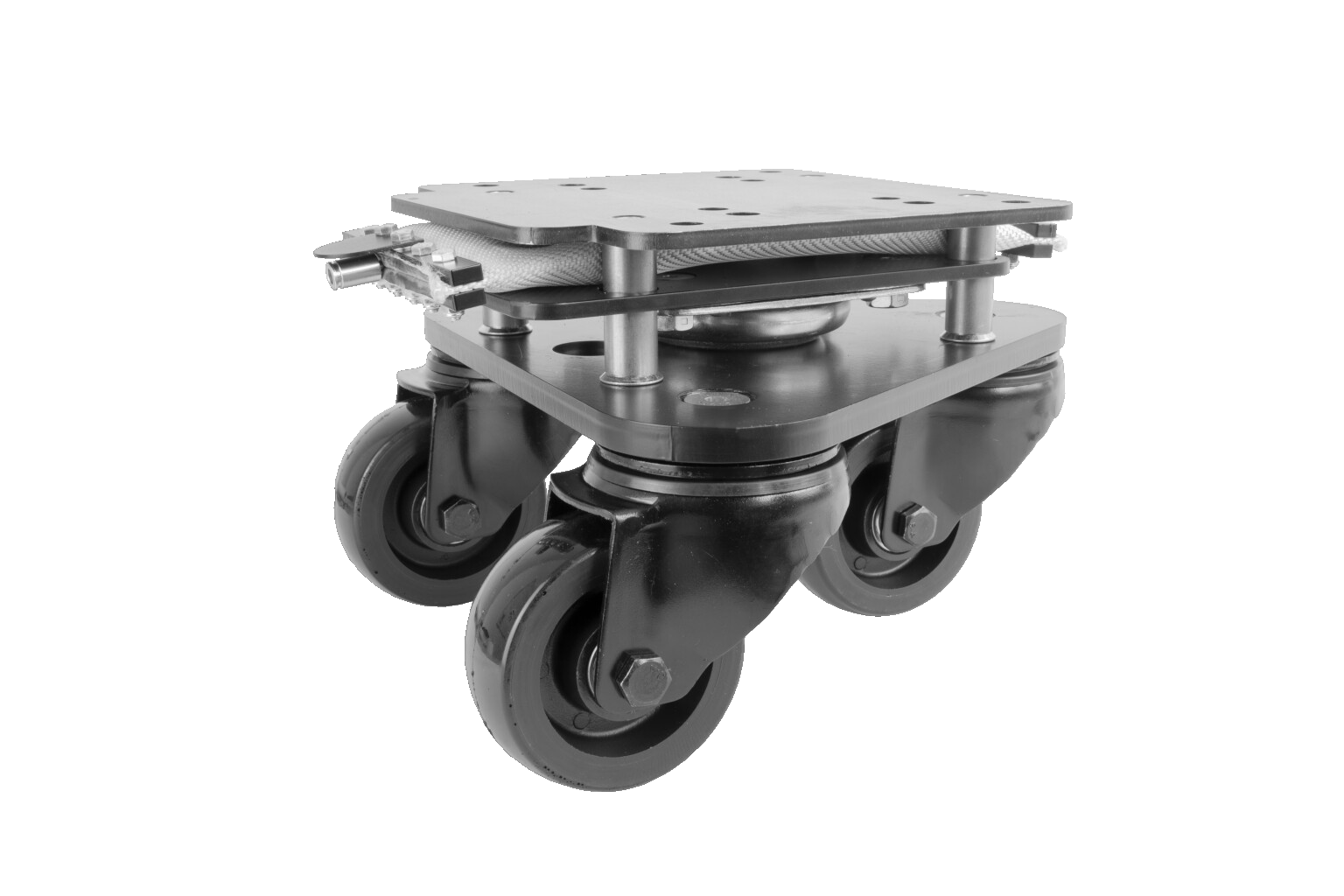

Swivel and Rigid Castors up to 10,000kg

Stainless Steel Castors

Stainless Steel Heavy-Duty Castors

Heat-Resistant Wheels

ESD Castors

Locking Castors

Lifting Rollers

Triangular Rollers

Stagelifter

Leiterrollen

End Caps

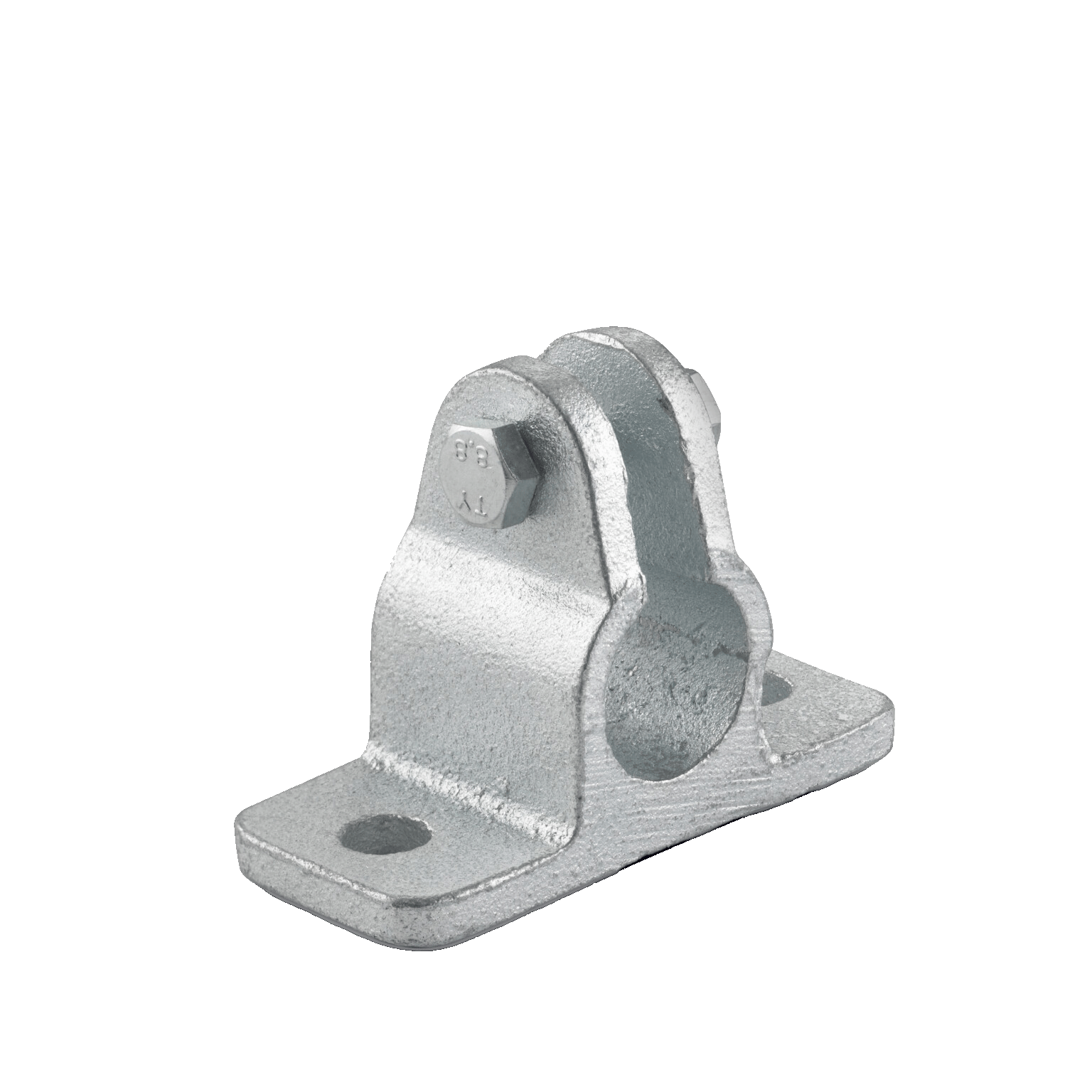

Axles and Axle Brackets

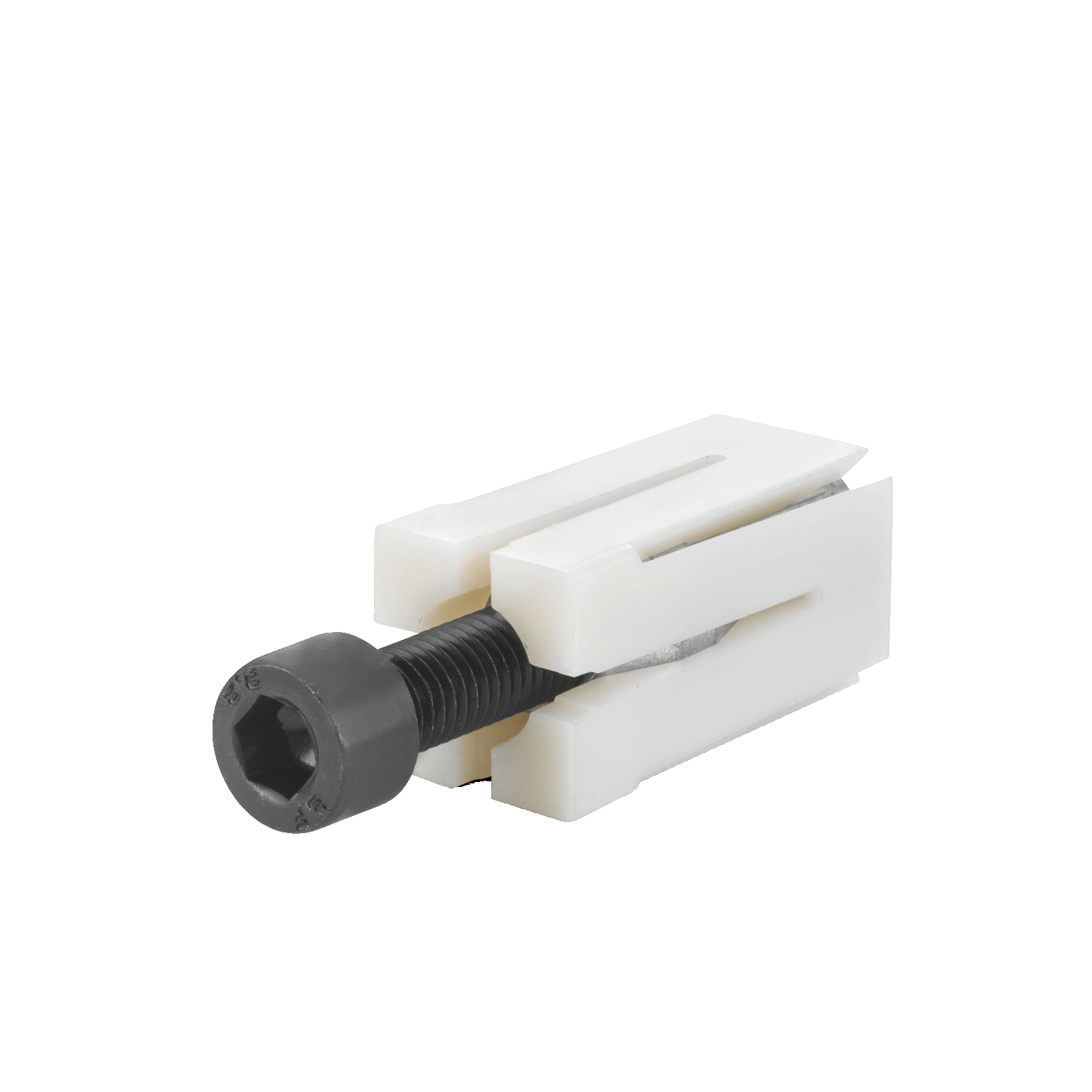

Fasteners for Swivel Casters

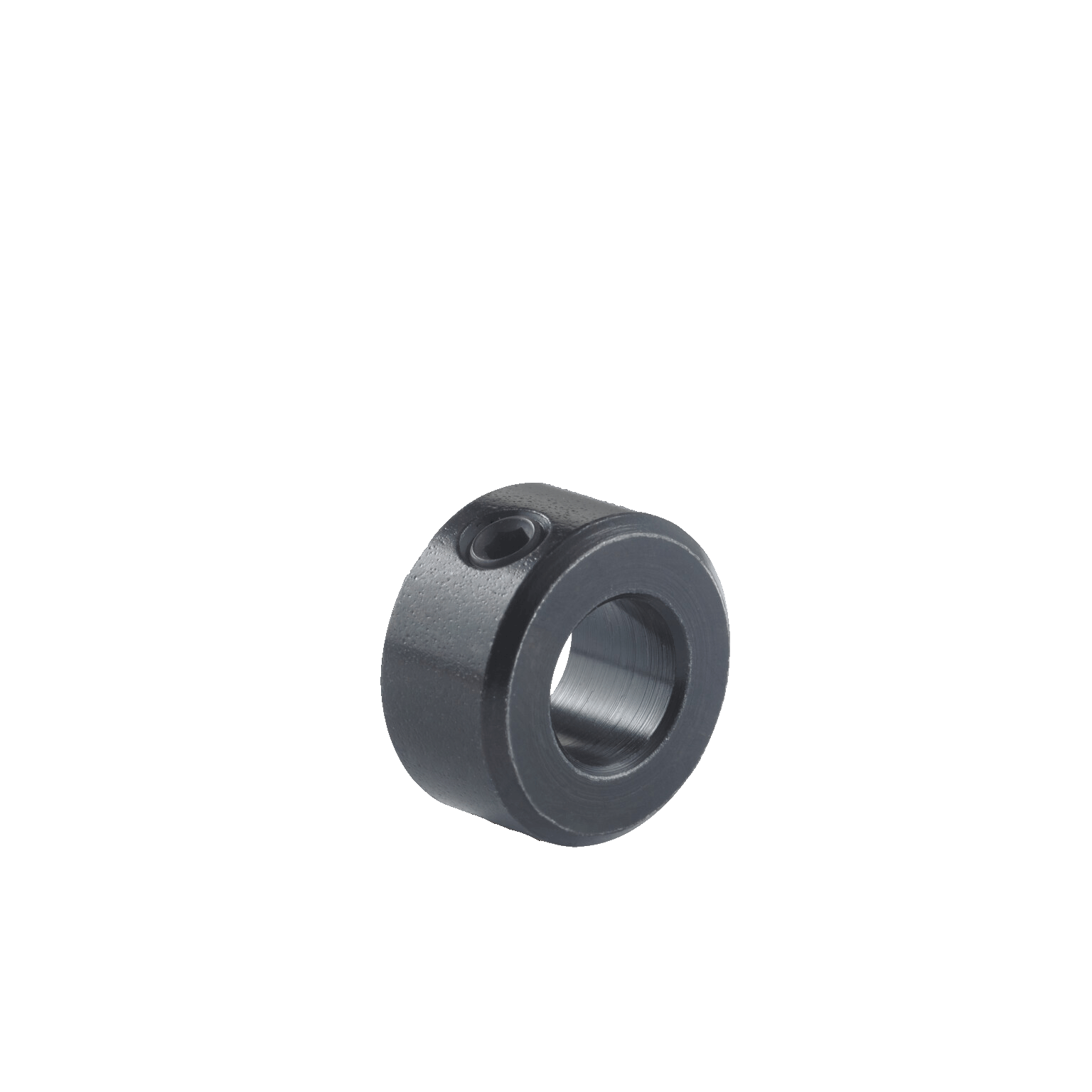

Set Collars

Bearings

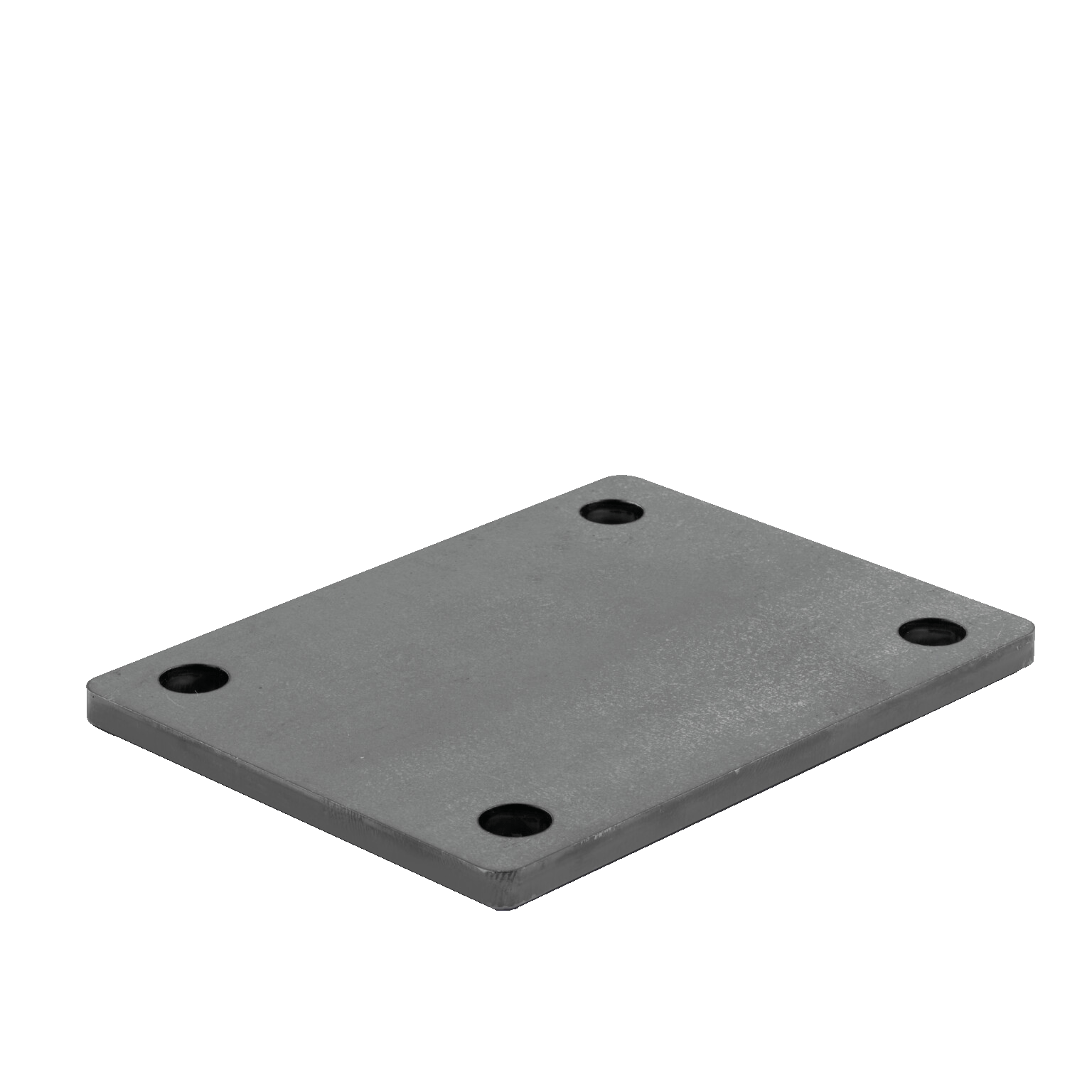

Mounting Plates

Deflector Wheels

Foot Protection

Castor Housings

We have been manufacturing customised solutions for all fields of application for over 60 years. We work closely with our customers during development.

‘Suppliers of castors and wheels not only need a comprehensive product range, but must also offer expert advice,’ says our Area Sales Manager for Bavaria, Roberto Gregorini. The wheels and castors, which are produced as individual items, small batches or large runs, are used in industrial companies, paint shops, chemical plants, hospitals, the food and automotive industries, furniture and packaging manufacturers, for example.

Due to the different requirements placed on the products, customised designs are often used nowadays. ‘Customised production processes are naturally more complex than the delivery of standard components,’ says Gregorini. Delivery within 24 hours, as we usually guarantee for our standard range, is not possible for customised products.

TORWEGGE produces wheels and castors ranging in size from 30 to over 900 mm and with a load capacity of between 450 kg for standard castors and 10,000 kg for heavy-duty castors. Depending on the intensity of use and rolling speed, we equip them with plain bearings, roller bearings or ball bearings. The components are made of rubber, plastics such as polyamide or polypropylene and metals such as steel, cast iron or aluminium. Depending on their intended use, they are therefore resistant to heat, cold, germs or chemicals, do not rust, do not absorb odours or are electrically conductive.

In the first step, we develop prototypes and subject them to intensive internal quality testing. For this purpose, we have a test bench on which all wheels and castors can be tested in real time in various application specifications. ‘We can also simulate journeys and obtain reliable data,’ explains Gregorini. The products are then presented to our customers and all technical parameters, such as friction coefficients, drive torques, starting resistances and dynamic load-bearing forces, are made available. Only when you are satisfied with the prototypes do you make your purchase decision and initiate the production of the wheels and castors in the desired quantity.

Our TORWEGGE wheels and castors make it easy and convenient to move goods. Depending on the tread, tyre, rim, wheel centre and bearing, different load capacities, rolling resistances and running properties are achieved. These are each suitable for specific applications such as trolleys, trolleys, roll containers, shelf trolleys or heavy-duty transport trolleys. When selecting wheels, you should also take into account environmental influences, the nature of the roadways and chemical requirements at the place of use. By selecting the right castors and wheels, you can meet these requirements precisely. In this way, you can optimise your various transport devices and move them with the lowest possible rolling resistance. The wheels and castors are also suitable as high-quality spare parts so that worn wheels and castors do not pose a safety risk.

Before you decide on a model, there are a few factors to consider when buying wheels and castors, as they are available in different designs and for specific purposes. We describe below what these factors are and how you can find the right wheels and castors for your requirements.

Firstly, you should decide which design is suitable for the application. The tread, rim, wheel bearing and running surface are different in each case, which should be taken into account when making a purchase decision. It is then important to define where the wheels and castors are to be used. Depending on the design, these can be used with fixed or swivel castor housings. Swivel housings can be rotated through 360°, which enables a change of direction in all directions. In contrast, wheels and castors in fixed housings are fixed and cannot be moved, which ensures directional stability.

Transport devices often have a combination of both forms in order to achieve an optimum steering function. The suitability of the wheels and castors for different types of transport equipment is just as important as the floor condition and the locking and doubling function.

Another selection criterion is the tyres. When selecting the material of the wheels and castors, the floor on which they are to be used should be taken into account. In general, wheels and castors with a hard tread work better on soft floors, while a soft tread is ideal for firm surfaces. However, this categorisation alone does not go far enough, as the wheels and castors must also be adapted to other requirements. In production halls and factories, for example, chemical resistance must be ensured so that they are not damaged by chemical contamination. In addition, particularly abrasion-resistant and robust materials must be used if, for example, rough floors or knocks and bumps are to be expected. In many areas of application, the starting and rolling resistance must also not be too high.

Wheels and castors made of polyamide or nylon have low rolling resistance, high load-bearing capacities and a long service life. They are also abrasion and chemical resistant. The disadvantage is that they run comparatively noisily, which is why they are best suited for smooth and even floors.

Polyurethane as a material for wheels and castors also offers many advantages. It is highly resilient and cut-resistant and, like polyamide, abrasion-resistant, chemically resistant and has low collision resistance. Polyurethane is also extremely low-wear.

Wheels and castors made of solid rubber are suitable for uneven floors as they run very smoothly and can be moved without damaging the floor. The disadvantages, however, are the lack of abrasion resistance and chemical resistance, as well as the chalking property.

Alternatively, wheels and castors made of thermoplastic elastomer/rubber can be used, which are ideal for sensitive surfaces and medium weights. This material is characterised in particular by its very low rolling resistance and smooth running. In contrast to solid rubber, it is also abrasion-resistant and non-marking, but not chemically resistant.

Another material for wheels and castors is polypropylene, which is ideal for smooth, even floors. The low starting and rolling resistance as well as the chemical resistance are advantageous for a wide range of applications. However, this material is less abrasion-resistant and runs comparatively noisily should the surface become somewhat uneven.

Steel is an excellent material for wheels and castors for particularly heavy loads. Steel offers low rolling resistance, extreme wear and pressure resistance, resistance to oils and greases and is also electrically conductive, which makes it ideal for applications in conveyor and transport technology. However, steel is not resistant to all chemicals, which should be taken into account when purchasing.

Discover the popular ‘Blue Wheel’ castors from TORWEGGE, which impress with their soft, blue elastic rubber coating on a robust polypropylene rim. These special castors are non-marking and quiet, making them an ideal choice for use in the theatre or on stage. But they also ensure quiet and comfortable use in private environments. The ‘Blue Wheel’ castors are available in various sizes, including Ø 80, 100, 125, 160 and 200.

In addition, the thermoplastic rubber wheels can also be purchased individually as spare parts to replace your existing castors quickly and easily. For smaller or more specific requirements, we also offer equipment castors with thermoplastic or polyurethane wheels.

The high-quality castors are fitted with a galvanised sheet steel plate with standardised hole spacing and can be easily screwed to the desired object. Alternatively, the back-hole fastening allows the castors to be securely mounted with just a single screw. Thanks to the integrated roller bearings, these products guarantee easy and effortless movement.

The type of bearing used has a significant influence on the performance, durability and efficiency of the wheel or castor.

Plain bearings are simple bearings where the shaft or axle moves across a lubricated surface. They offer a robust construction and high impact resistance, making them ideal for applications with low to medium loads and low speeds. Thanks to their simple design and low maintenance requirements, plain bearings are often used in applications demanding reliability and durability, such as wheelbarrows, hand carts, or agricultural equipment.

Roller bearings, on the other hand, consist of cylindrical rollers arranged between inner and outer rings. These rollers reduce friction and enable smooth movement of the shaft or axle. Compared to plain bearings, roller bearings offer higher load capacity, making them suitable for applications with greater loads and speeds. They are commonly used in industrial settings such as conveyor belts, transport carts, or machinery.

Ball bearings are the most widely used type of bearing, consisting of balls arranged between inner and outer rings. These balls reduce friction and allow smooth movement of the shaft or axle in all directions. Ball bearings offer even higher load capacity and efficiency than roller bearings, making them ideal for applications with heavy loads and high speeds. They are used in a wide range of applications, including mechanical engineering and other high-performance uses.

To ensure that wheels and castors fit their respective transport devices and provide safe and stable handling, the dimensions of various components must be considered. Key factors include the wheel and tread width, wheel and axle diameter, as well as the hub length for proper fit. For swivel wheels and castors, additional measurements such as the swivel radius, offset, overall height, mounting plate, swivel fork, and axle material should also be taken into account to determine the correct fit. Furthermore, when using a mounting plate, the hole diameter and spacing, as well as the plate’s length and width, must be considered.

Determining the load capacity of wheels and castors is crucial for optimal movement and minimizing wear. This ensures safe operation, as load capacity depends not only on the wheel material but also on the diameter. Larger diameters provide a greater contact surface, distributing the weight over a larger area and thereby reducing pressure. This results in higher load capacity, as the load is more evenly spread across the wheels and castors.

Discover the wide range of wheels and castors at TORWEGGE! We offer a diverse selection of high-quality products in various diameters, designs, and load capacities to meet your specific needs. In our online shop, you can customize the diameter and load capacity of the products to suit your individual requirements. Whether you're looking for durable wheels and castors for heavy-duty industrial use, medium loads, or sensitive applications, you're guaranteed to find the perfect solution with us. Rely on the quality and reliability of TORWEGGE!

No matter which application you need wheels and castors for, TORWEGGE's extensive online shop offers the right solution for your business. For particularly innovative applications, we also provide lift castors, which use a foot pedal to lift workpieces, making them easy to transport. These are ideal for workbenches or work tables. Additionally, our shop offers accessories for wheels and castors, allowing you to customize your transport solutions to meet your specific requirements. If you can’t find the right component, we also offer tailored solutions of the highest quality—efficient, innovative, and at attractive prices. Browse our online selection and trust our extensive expertise in conveyor and handling technology.

When it comes to developing advanced transport solutions, seeking expert support is highly recommended. TORWEGGE is your trusted partner for all matters related to conveyor and transport technology. Our team of experts is happy to assist with any questions or concerns you may have. Contact us for a consultation! We are here to help and will provide customized transport solutions tailored to your individual needs and requirements.