Spring Balancers and Tool Balancers – Say Goodbye to Tedious Bending

Spring balancers and tool balancers are practical tools designed to simplify and speed up work at production and assembly stations. Tools can be suspended from them, allowing for quick and effortless tool changes. This not only saves time but also keeps the workspace organized and ergonomically optimized to meet individual needs.

Get your spring balancers or tool balancers now!

2300 mm

2,0 kg to 3,5 kg

0,65 kg

2000 mm

16,0 kg to 21,0 kg

4,536 kg

1600 mm

0,4 kg to 1,0 kg

0,6 kg

2500 mm

0,5 kg to 2,0 kg

0,927 kg

2500 mm

10,0 kg to 14,0 kg

4 kg

2000 mm

10,0 kg to 15,0 kg

10,3 kg

2300 mm

0,5 kg to 1,0 kg

0,35 kg

3000 mm

2,0 kg to 5,0 kg

3,885 kg

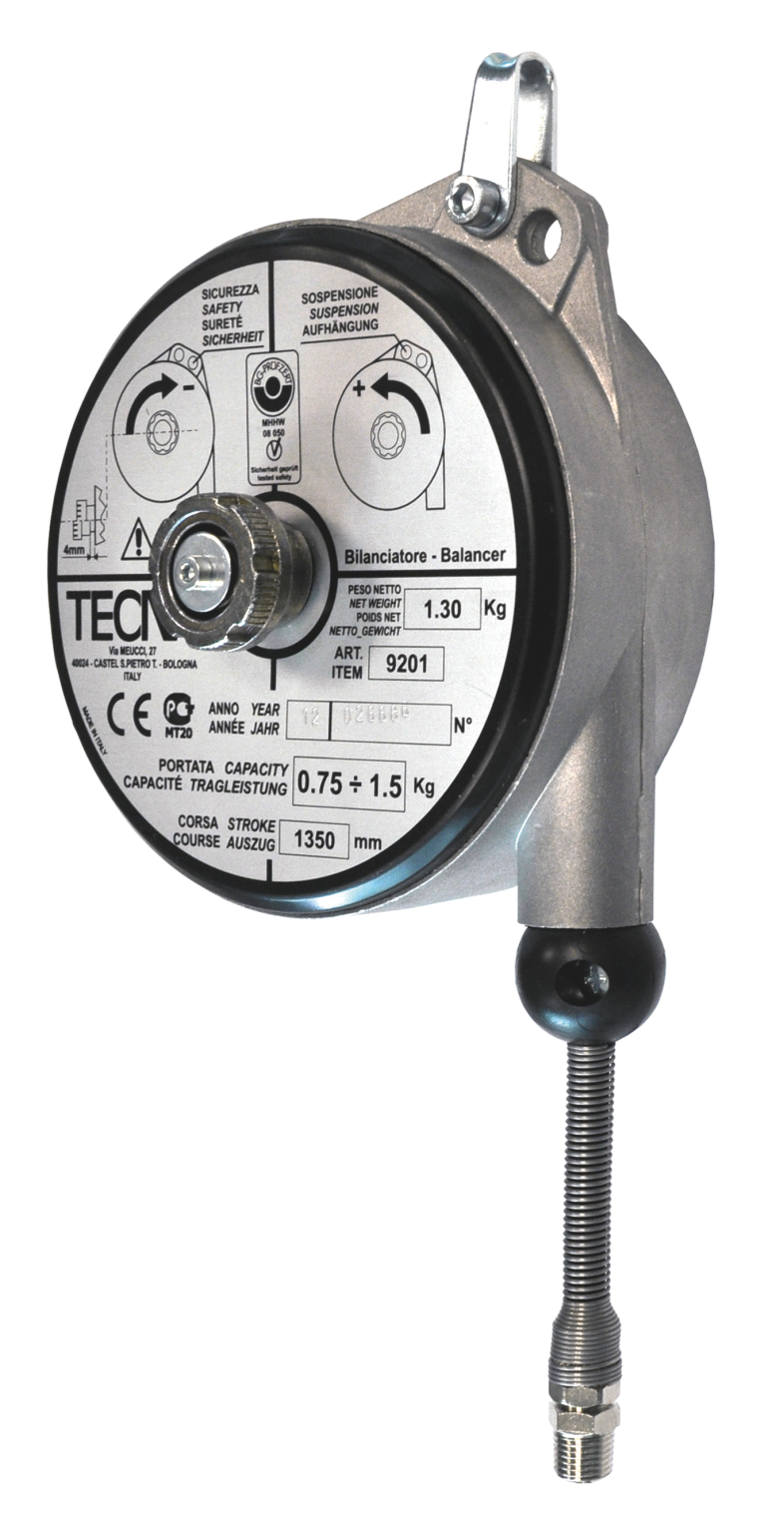

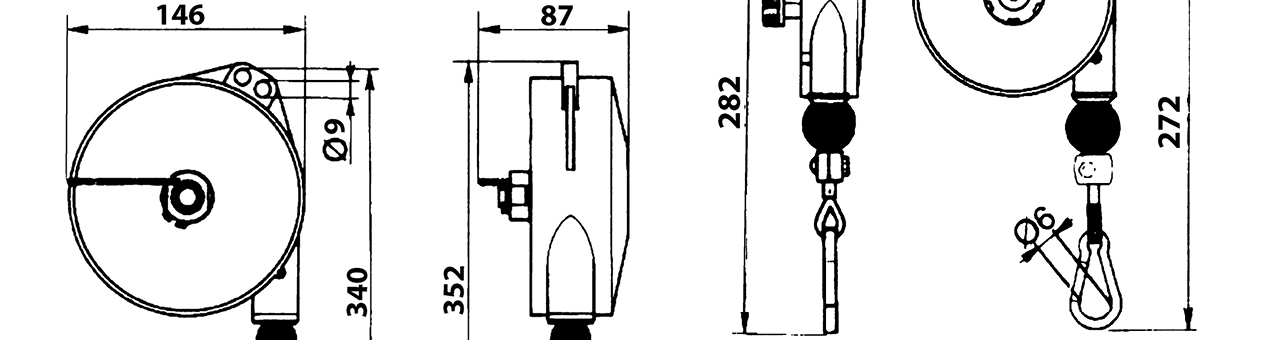

1350 mm

0,7 kg to 1,5 kg

1,2 kg

1600 mm

1,2 kg to 2,6 kg

1,516 kg

1600 mm

1,2 kg to 2,5 kg

0,669 kg

Spring Balancers and Tool Balancers at TORWEGGE

Spring balancers and tool balancers are mechanical devices used in industrial environments to facilitate lifting, lowering, or balancing tools, equipment, or other objects. They are designed to reduce physical strain on workers and enhance efficiency in production processes, contributing to an ergonomically optimized workplace.

A spring balancer is a mechanical device that offsets the weight of a load by applying counterforce using hydraulics or electric drive. Tools to be lifted can be attached and positioned using a cable with a carabiner. After use, the cable automatically retracts to its starting position, which is why spring balancers are also referred to as "retrievers."

Similarly, a balancer compensates for the weight of a tool, allowing it to remain in a stable position thanks to its conical design. This functionality has earned balancers the alternative name "weight equalizers."

Spring balancers and balancers are widely used in industrial applications, such as screw technology, electric or pneumatic tools, slaughter machinery, and robotic feed systems.

Features and Applications of Spring Balancers

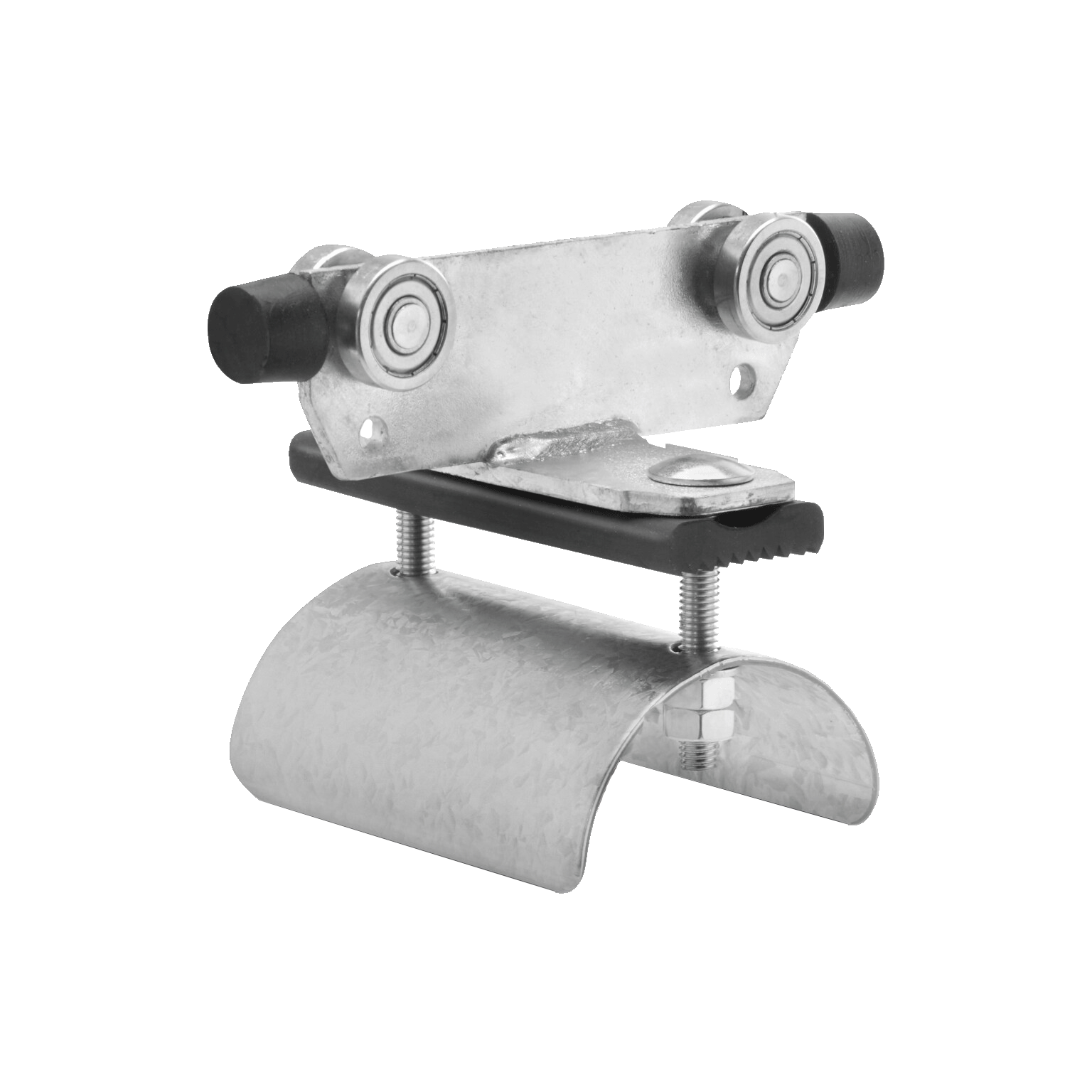

A spring balancer is primarily designed for tool suspension, such as electric screwdrivers, and for guiding cable bundles, particularly in robotic workstations. Spring balancers use a spring mechanism to counterbalance the weight of an object. They feature a drum body around which the cable is wound, keeping the attached tool in a near-weightless state. Operators can easily pull the tool into the desired working position, with only minimal retraction force being applied. When the tool is released, the cable automatically retracts to its original position. By balancing the weight, lifting or lowering the tool becomes almost effortless, significantly reducing the strain on workers.

Spring balancers are available with or without a locking mechanism. A locking mechanism allows the cable to be fixed at incremental levels, enabling the load to remain at a specific height. A quick additional pull releases the lock, and the tool returns to its resting position. The cables used in spring balancers, made of high-quality stainless steel or nylon, are housed within painted steel casings of varying sizes depending on the model. Before attaching a tool, the balancer’s weight range should be adjusted to match the load.

Spring balancers are indispensable for creating ergonomic workstations. Heavy tools no longer need to be lifted manually but can be suspended and used freely with the support of the balancer. This not only makes workflows more efficient but also alleviates physical strain on employees. Investing in a spring balancer can provide long-term benefits by reducing production costs and improving workplace ergonomics.

At TORWEGGE, spring balancers are available in various configurations. Models with nylon cables are available in a length of 2,300 mm, while stainless steel variants come in lengths of 2,000 mm or 2,500 mm. The robust cables are known for their durability. Spring balancers with nylon cables support loads ranging from 0.5 to 8.5 kg, whereas stainless steel cable models handle weights between 4 and 14 kg. All spring balancers come with an adjustable load range to suit specific needs.

Installation should always be carried out by trained personnel following the included operating instructions to avoid potential damage or injury. It is important to note that spring balancers are not lifting devices, so their function is not intended for switching loads. Proper use ensures optimal performance and safety in any workspace.

Features and Applications of Tool Balancers

Tool balancers are designed to maintain the weight of an object in a suspended state, enabling easy positioning and movement. This makes them particularly useful when tools or equipment are needed at various positions. Workers in screw technology, electric and pneumatic tool operations, slaughter machinery, and robotic feed systems benefit greatly from using balancers and spring balancers. Additionally, devices such as labeling tools, soldering irons, and packaging equipment are excellent candidates for use with a spring balancer or tool balancer.

Balancers hold tools in a weightless state at a desired position, making them ideal for precision work that requires a high level of dexterity. Primarily, they are used to reduce the physical strain of working with handheld tools, but they also support linearly guided tools. Unlike spring balancers, balancers feature a conically shaped drum body. This design ensures that the spring force remains nearly constant (linear) in relation to the cable extension length. Due to this consistent increase in spring force compared to retraction force, balancers are preferred for handling heavier loads.

Like spring balancers, balancers are also available with locking mechanisms. While spring balancers typically support loads up to 14 kg, balancers can handle weights of up to 180 kg, making them indispensable for tasks involving heavy-duty equipment. This combination of versatility and strength makes tool balancers a crucial component in ergonomic and efficient work environments.

Advantages of Spring Balancers and Tool Balancers

Spring balancers and tool balancers are primarily used in environments where heavy equipment is handled, and ergonomic workstations are essential. Their most significant advantage lies in substantially reducing the physical strain on employees, as lifting or lowering loads becomes much easier.

This simplification accelerates workflows by making it quicker and easier to position tools or equipment. Moreover, the use of spring balancers and tool balancers decreases physical exertion, helping to minimize injuries and muscle strain among workers.

In addition to enhancing ergonomics, these devices enable precise positioning of tools or objects, which improves accuracy in tasks requiring high precision. This combination of efficiency, safety, and accuracy makes spring balancers and tool balancers indispensable in many industrial applications.

Buy Spring Balancers and Tool Balancers Online at TORWEGGE

Spring balancers and tool balancers are used in various industries, including manufacturing, assembly, maintenance, the automotive sector, and electronics production - anywhere heavy tools or equipment need to be managed. For creating ergonomic workstations, alleviating employee strain, and optimizing workflows involving heavy loads, spring balancers and tool balancers are indispensable. They enable the handling of even very heavy transport goods while facilitating faster and more efficient operations.

At TORWEGGE's online shop, we offer spring balancers and tool balancers for a range of load capacities. Please review the detailed product descriptions, and don’t hesitate to contact us if you’re uncertain about selecting the right product.

Looking for additional helpful products in the field of handling technology? Explore our selection of galvanized overhead rail systems, chain hoists, trolleys, or jib cranes and booms!