Precision craftsmanship, technological innovation

Welcome to TORWEGGE plastics technology

We are passionate about designing cutting-edge solutions. From the idea to perfection, we focus on precision and innovation. With a highly skilled team and state-of-the-art technologies, we pride ourselves on developing bespoke injection moulding tools that inspire and drive industries forward.

What exactly does that look like?

We invite you to gain an insight into our product world, our way of working and our commitment to quality and sustainability.

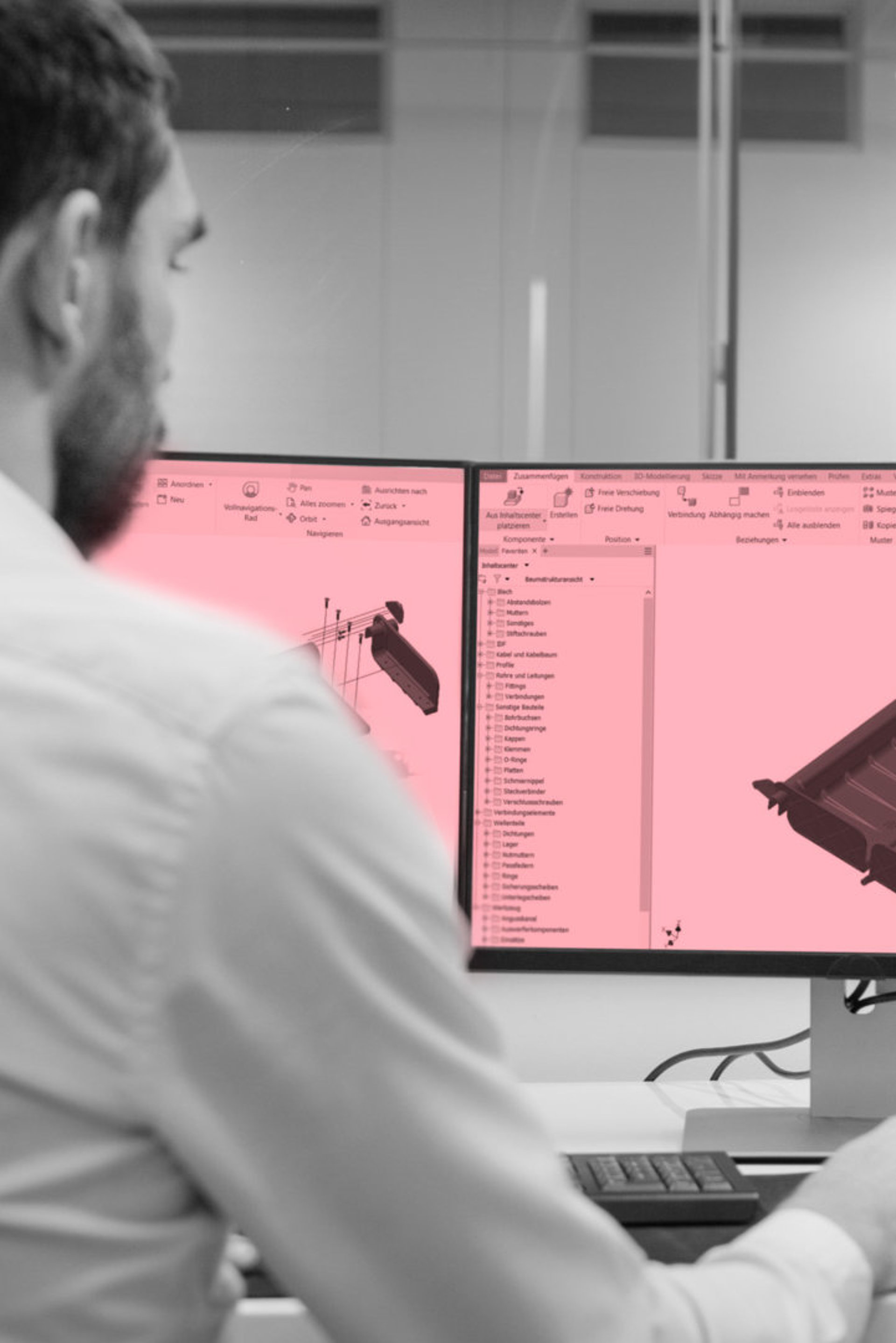

1 Development & Construction

TORWEGGE Kunststofftechnik: Everything under one roof, everything from a single source

From planning to delivery, everything is under one roof with us! An important step in this process and part of our service portfolio is the design of moulds and tools.

Our competent team uses the latest CAD/CAM technologies such as ‘Autodesk Inventor’ to transform your ideas into customised solutions. From your initial idea to the actual realisation, our experienced designers and developers work with you to develop individual concepts that focus on precision and reliability.

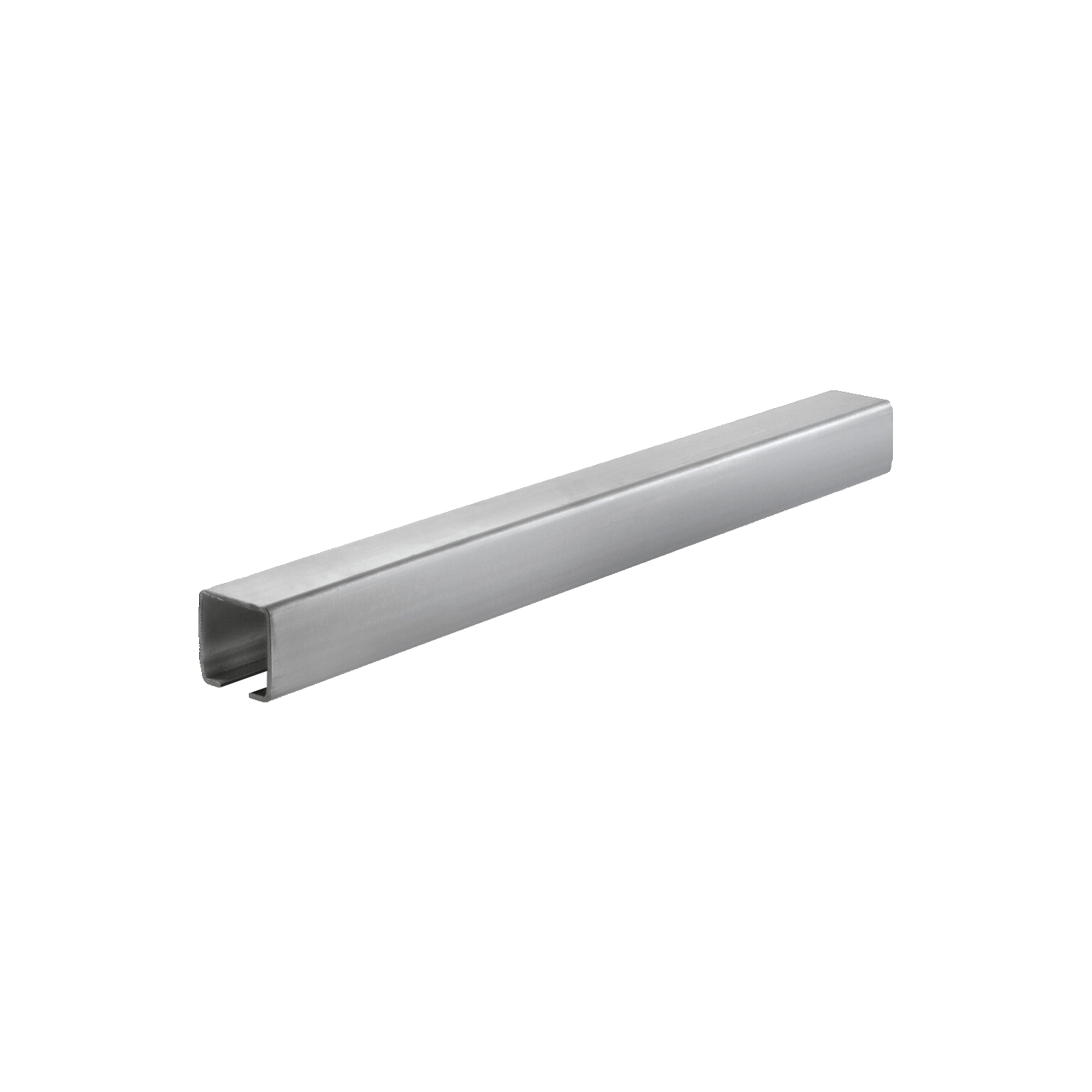

2 Tool- & mould making

The art of precision

TORWEGGE plastics technology relies on proven craftsmanship and modern technology in tool and mould making. In the targeted, flexible and creative realisation of your ideas, we therefore rely on comprehensive advice and support throughout the entire production process.

Machining centres and CNC milling machines as well as die-sinking EDM and grinding machines are available for your projects to achieve the best possible efficiency with the highest quality.

Our toolmaking machinery

- DMG Mori and Hermle machining centres up to 1000 mm travel

- Zimmer & Kreim CNC die-sinking EDM machines with a travel of up to 650 mm

- Turning and grinding machine

3 Injection moulding production

Moulding with precision

Our experienced and qualified team can draw on modern machinery to make your project a reality. This means that no compromises have to be made when it comes to meeting our quality standards.

We produce exclusively on injection moulding machines with 1- and 2-component technology from Demag with a clamping force of 350 KN to 3,000 KN and a maximum injection weight of 1,500 grams. All machines are equipped with 5-axis loading and removal robots and some have multiple core pulls and hot runner systems. Tailored to your project, all injection-mouldable plastics can be processed here.

3.1 Plastic selection

Thermoplastic materials

PA 6 | PA 6.6 | PA 6.10 | PA 12 | PA6T/6 | PA6T/6I | PA 4.6 | PBT | POM | ABS | PMMA | PPO | PPA | PAA | PES | PSU | PEI | LCP | PPS | PEEK | PAEK | PC-ABS | PC | PC-HT | PCT | PET | TPE-U | TPE-E | TPE-O | TPE-S | TPE-V

Reinforced plastics

Glass fibres | Carbon fibres | Glass beads | PTFE | Carbon | Long fibre materials | Special formulations

Specific plastics

with improved thermal conductivity | with EMC (electromagnetic compatibility | electrically conductive plastics | bio-based plastics with up to 100 percent renewable raw materials | friction-reduced plastics with teflon additives

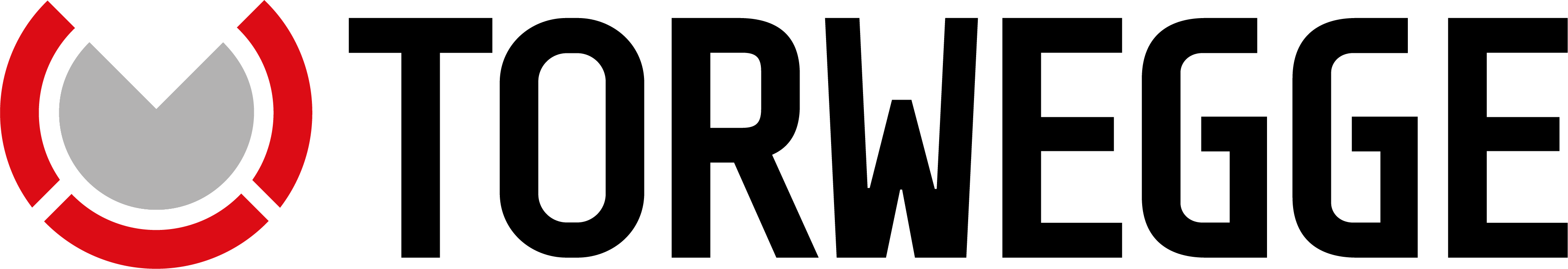

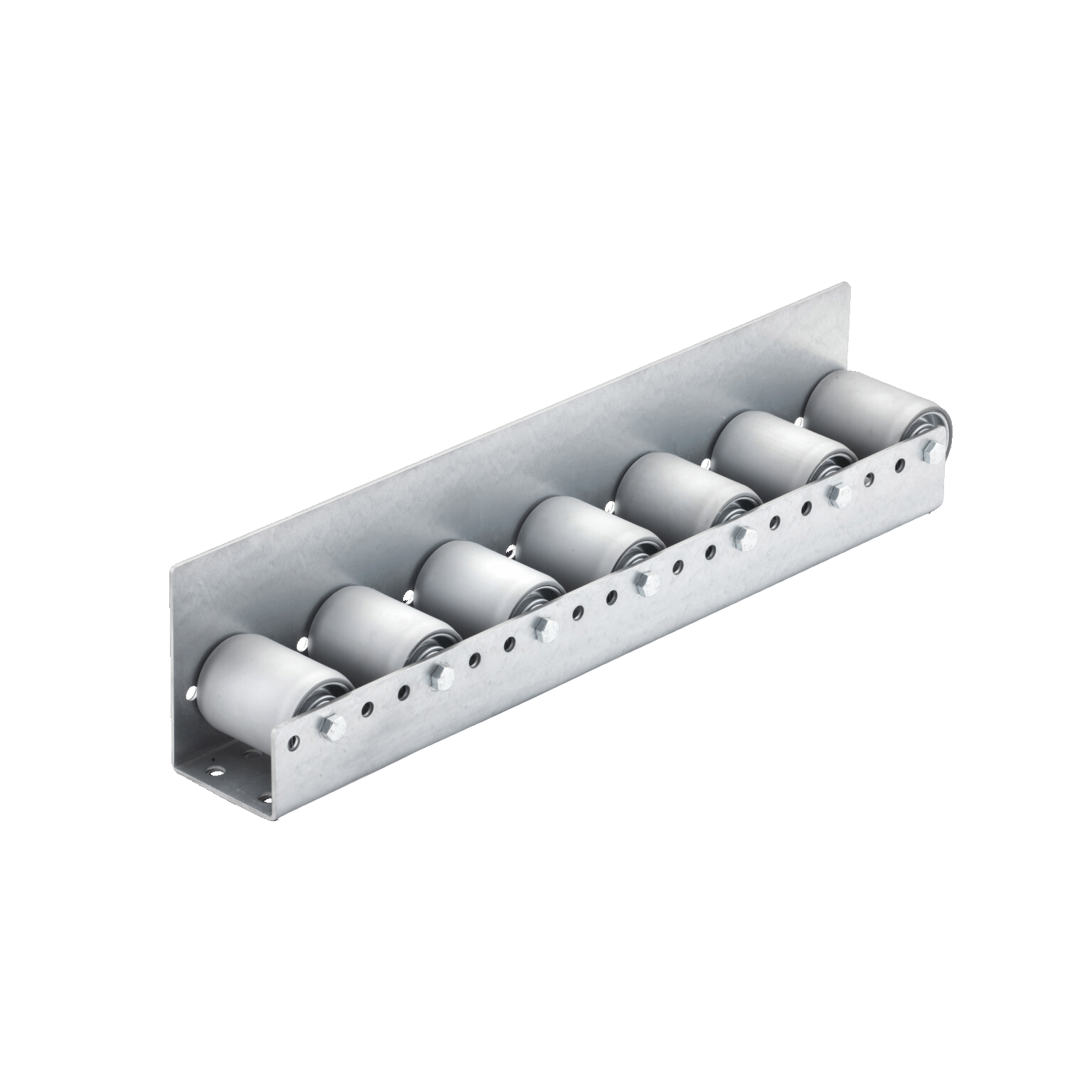

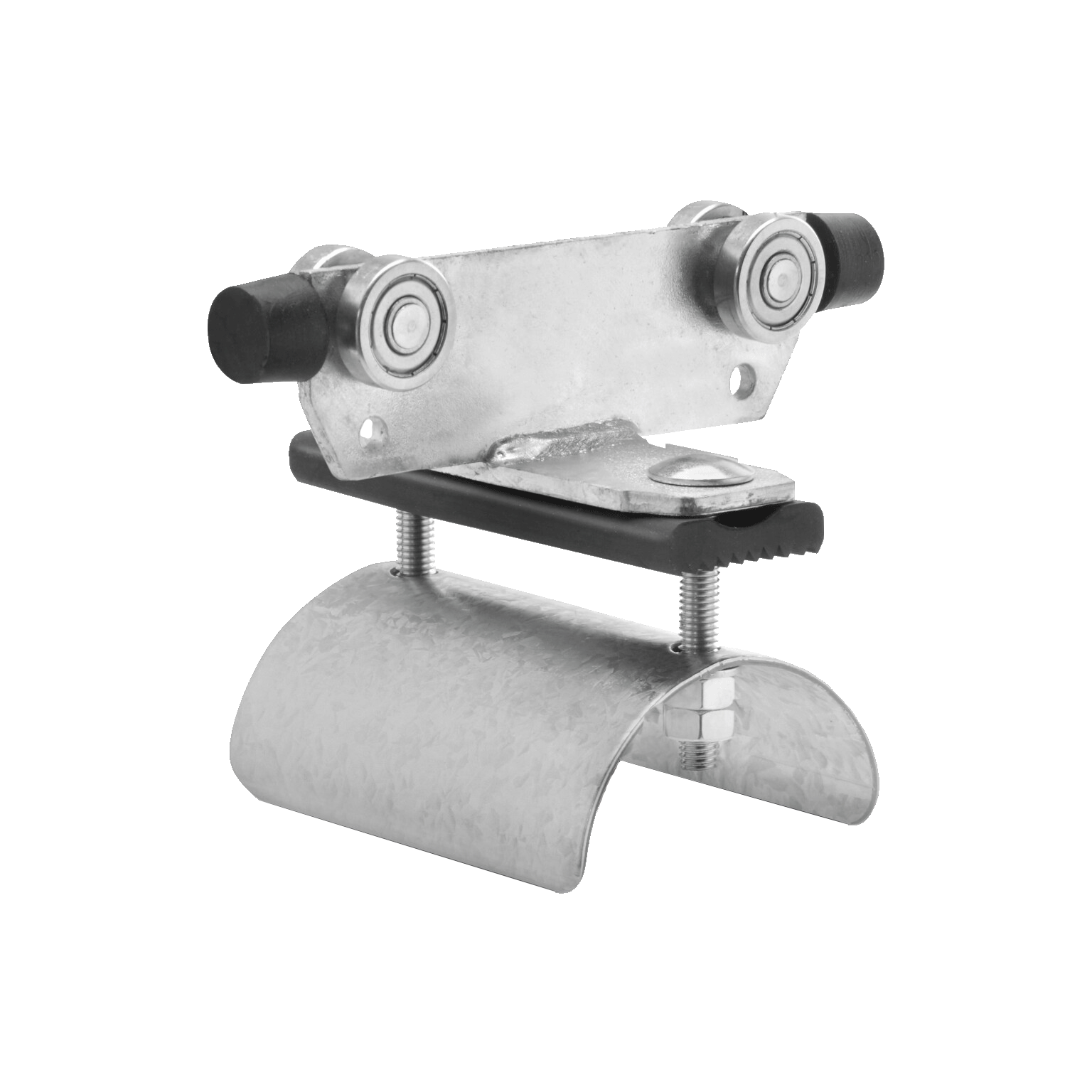

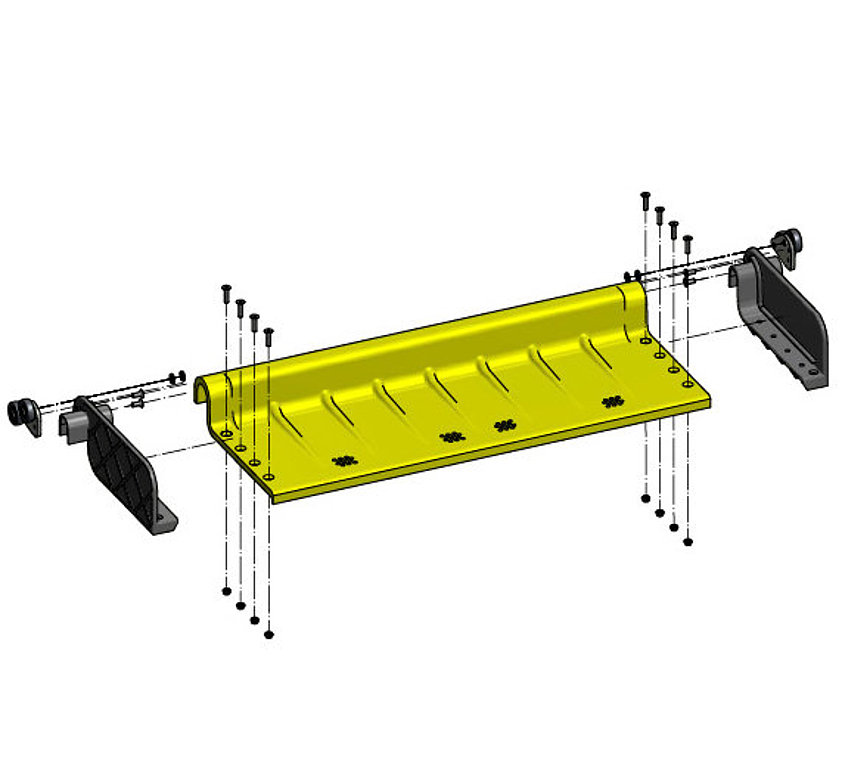

4 Component assembly

From individual parts to complete solutions

As a system supplier, TORWEGGE Kunststofftechnik offers the entire production chain for further processing: automatic processing of plastic articles and assembly of components - fully automatically or by hand for small series.

We realise everything for you, from small, lightweight products to thick-walled, heavy parts, from technical to visually sophisticated parts, from simple to complex articles/assemblies. Our high standard of automation guarantees maximum repeat accuracy. On request, we can offer you 3-shift operation in 24-hour production.

Philosophy & values

‘For us, the spirit of innovation, precision and perfection are inextricably linked. Our aim is to design the entire process from idea to reality and to set the highest quality standards in the process. Customer satisfaction is the cornerstone of our mission.’

Working methods & customer benefits

‘Our team provides comprehensive support, from the initial consultation to the final implementation. Thanks to state-of-the-art technologies and many years of expertise, we offer a flexible, efficient and precise way of working. The result: customised solutions that optimally meet the customer's needs.’

Sustainability

‘TORWEGGE Kunststofftechnik is actively committed to sustainability. We are happy to advise you on the advantages and possible applications of bioplastics. Our approach also includes the responsible use of resources and materials in order to promote environmentally friendly solutions.’

Your contact person

Dietrich Gossen is your personal contact for everything to do with TORWEGGE plastics technology. As an experienced department manager for projects and products, he has an eye for the big picture and can therefore advise you in detail.

Make an appointment now!

Dietrich Gossen

Head of department for

Projects und products

Tel.: +49 521 934 173 26

Mobil: +49 151 610 587 65

E-Mail: dietrich.gossen(at)torwegge.de