Standard Idlers

To optimize material flow in businesses as efficiently as possible, the use of conveyor systems is highly recommended. Conveyor technology is particularly essential in distribution centers, where it facilitates the transport of unit loads and bulk goods from point A to point B. With TORWEGGE's conveyor technology, you can enhance your internal material flow. Our components include conveyor rollers, roller conveyors, roller tracks, and ball transfer units. Upon request, we also deliver customized complete solutions tailored to your specific needs and support you right from the planning phase of your project. For more complex applications and/or automation solutions, our Intralogistic Solutions division is available to provide expert assistance.

TORWEGGE offers a comprehensive range of innovative solutions for transporting your goods. Browse our online shop and optimize your transport processes with TORWEGGE's conveyor technology!

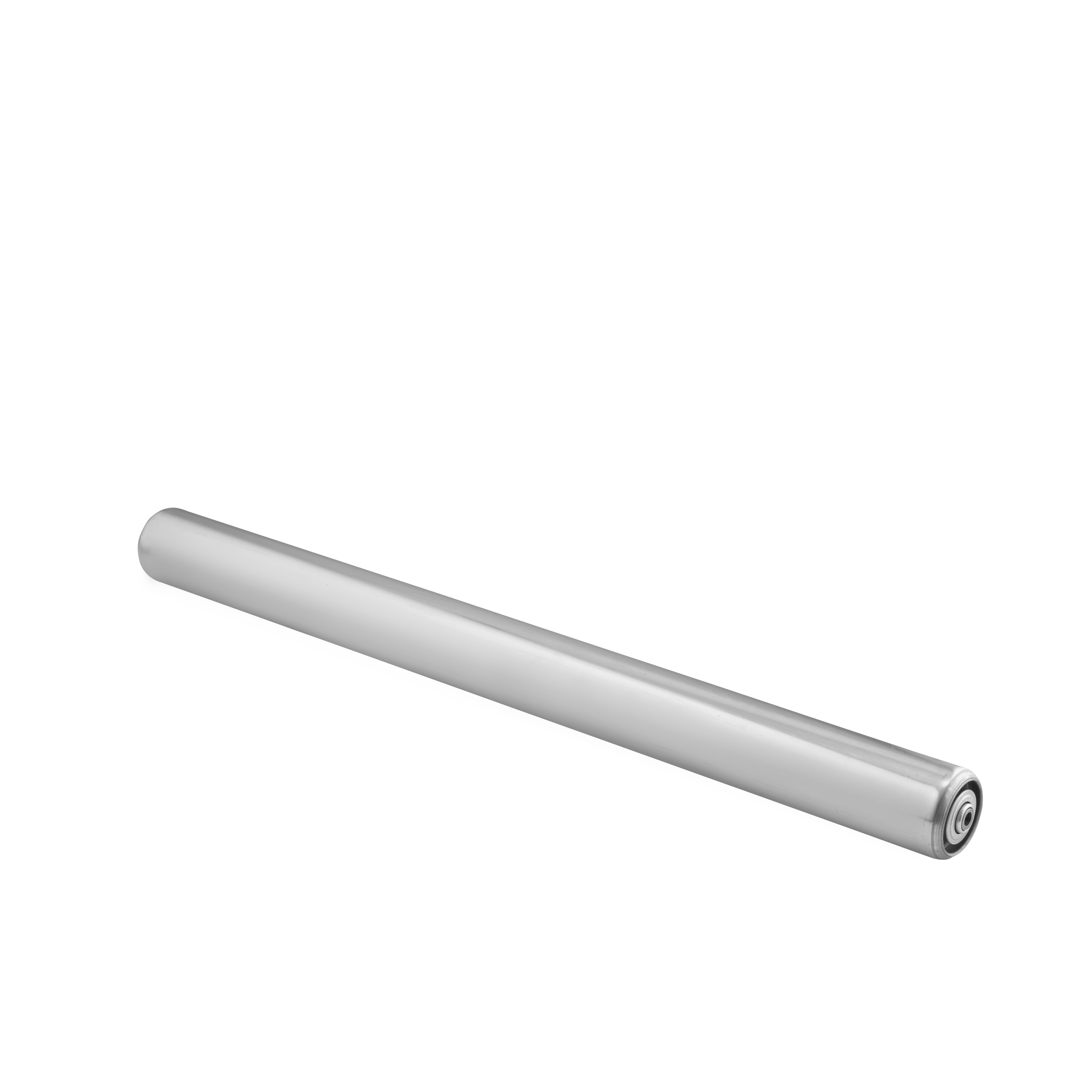

Standard Idlers

Drum Motors

Accessories for Idlers

Custom-Made Idlers

Ball Transfer Units with Steel Housing and Mounting Clips

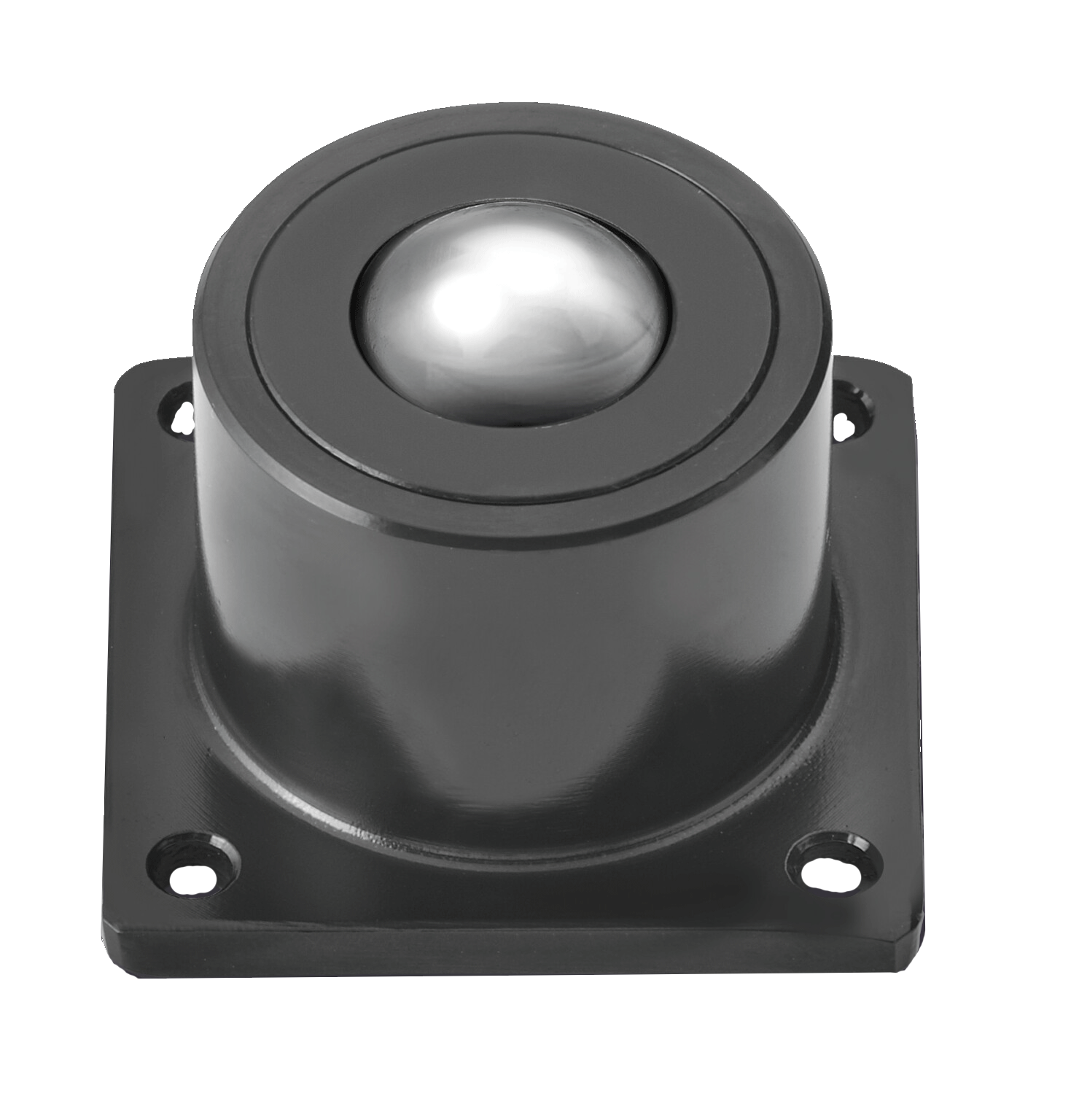

Solid Ball Transfer Units

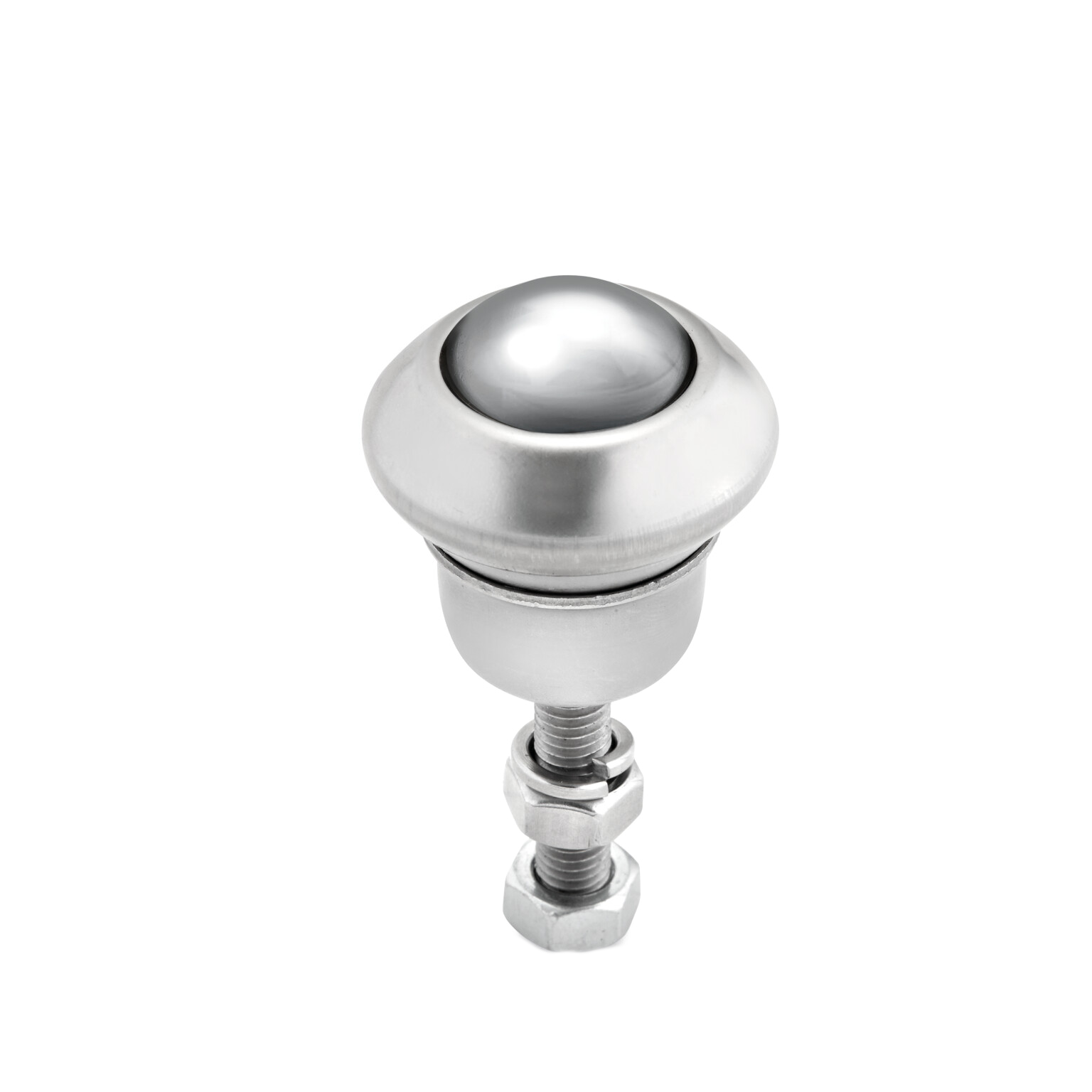

Ball Transfer Units with Threaded Studs

UFO Ball Transfer Units

Universal Ball Transfer Units

Mini Ball Transfers

Heavy-Duty Ball Transfers

Accessories Ball Transfers

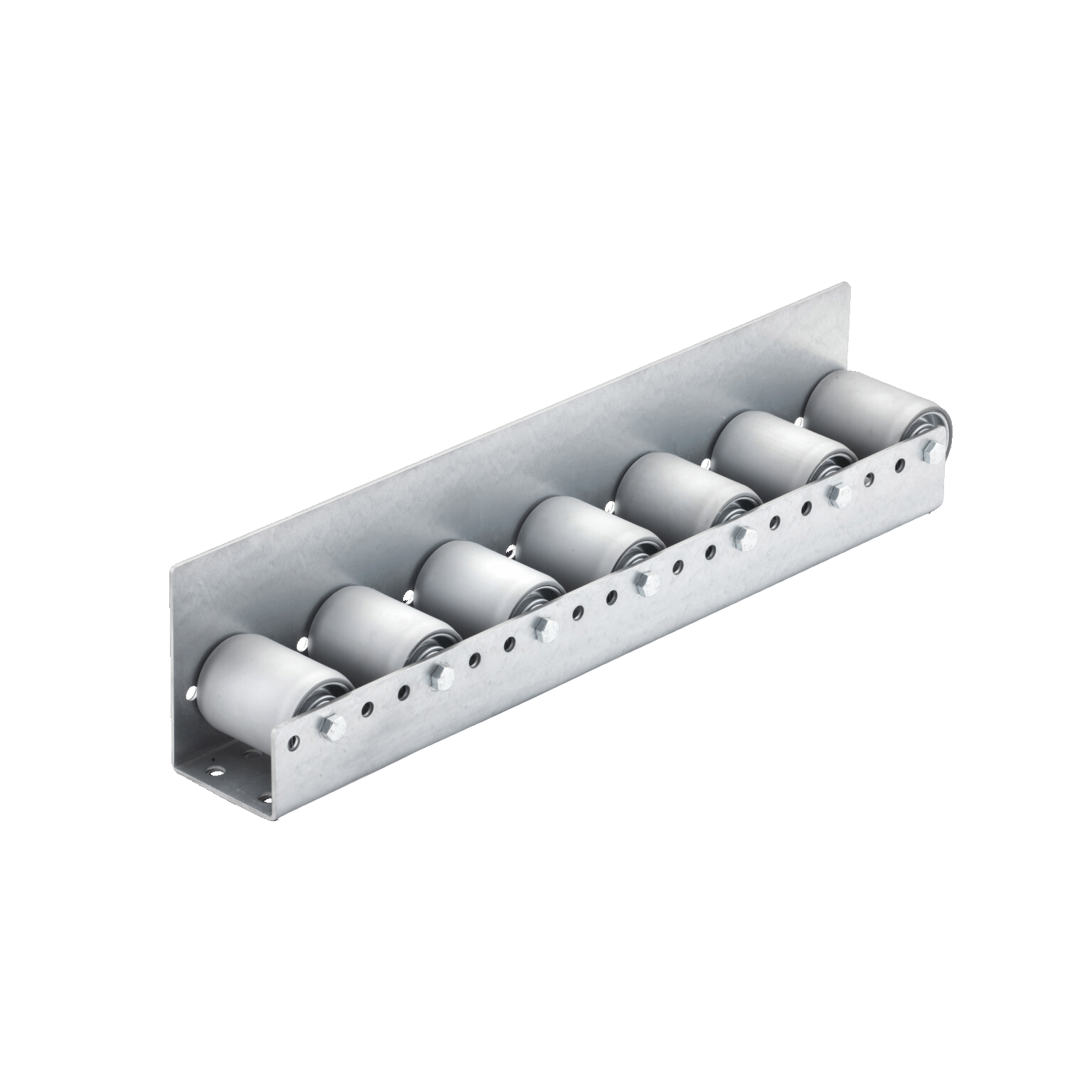

Small Roller Conveyors and Light Roller Conveyors

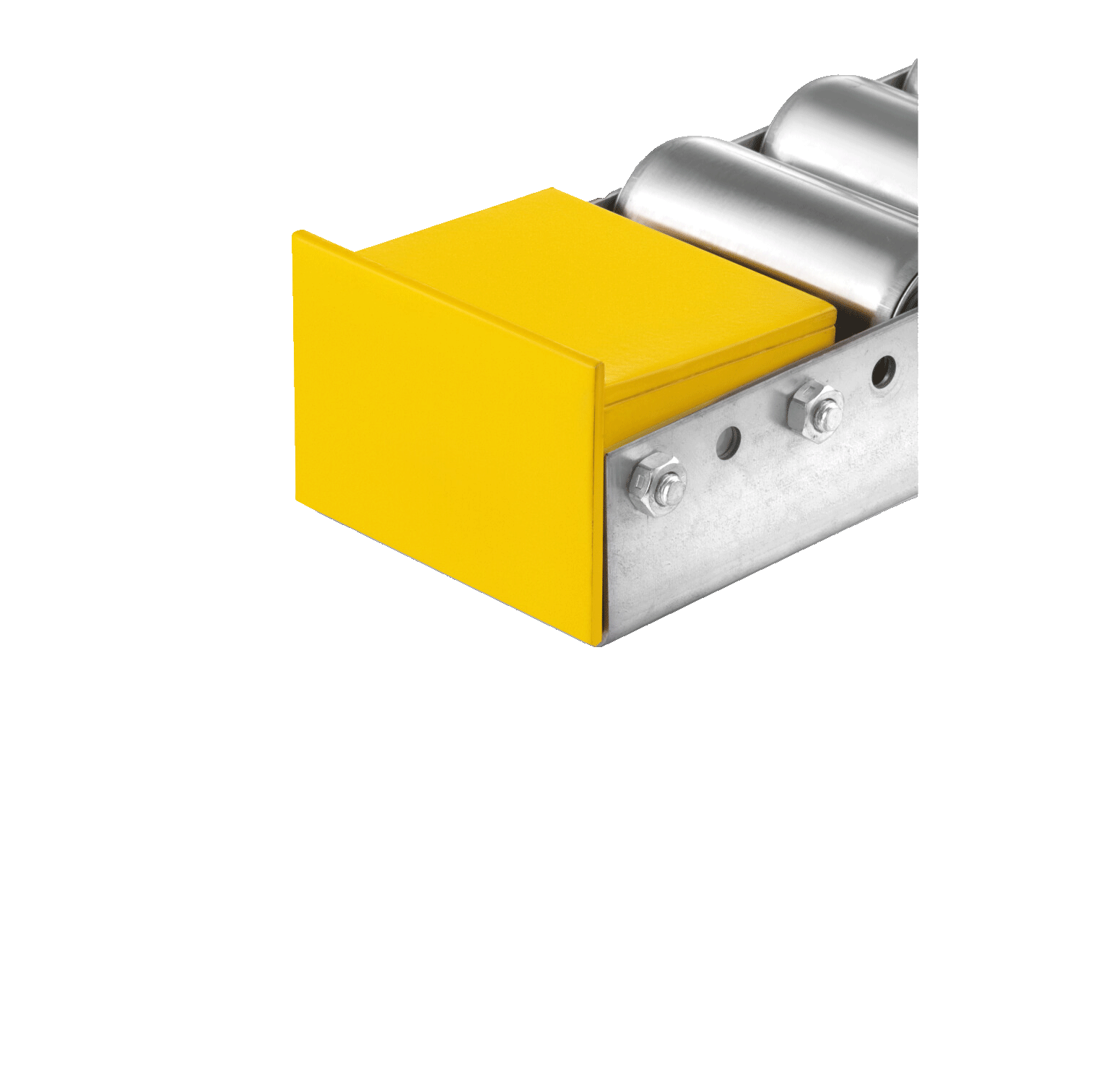

Accessories for Small and Light Roller Conveyors

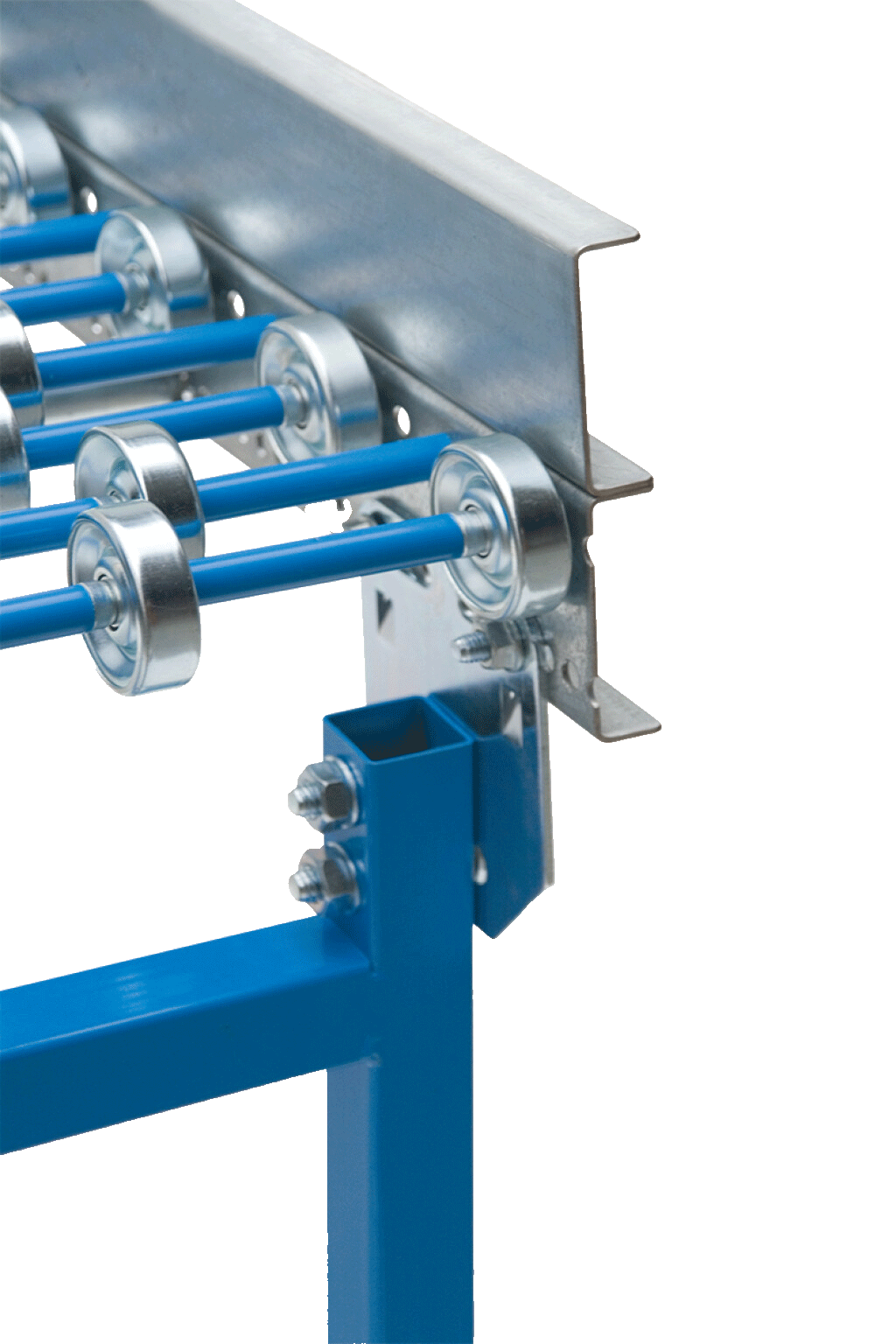

Roller Conveyors

Accessories for Roller Conveyors

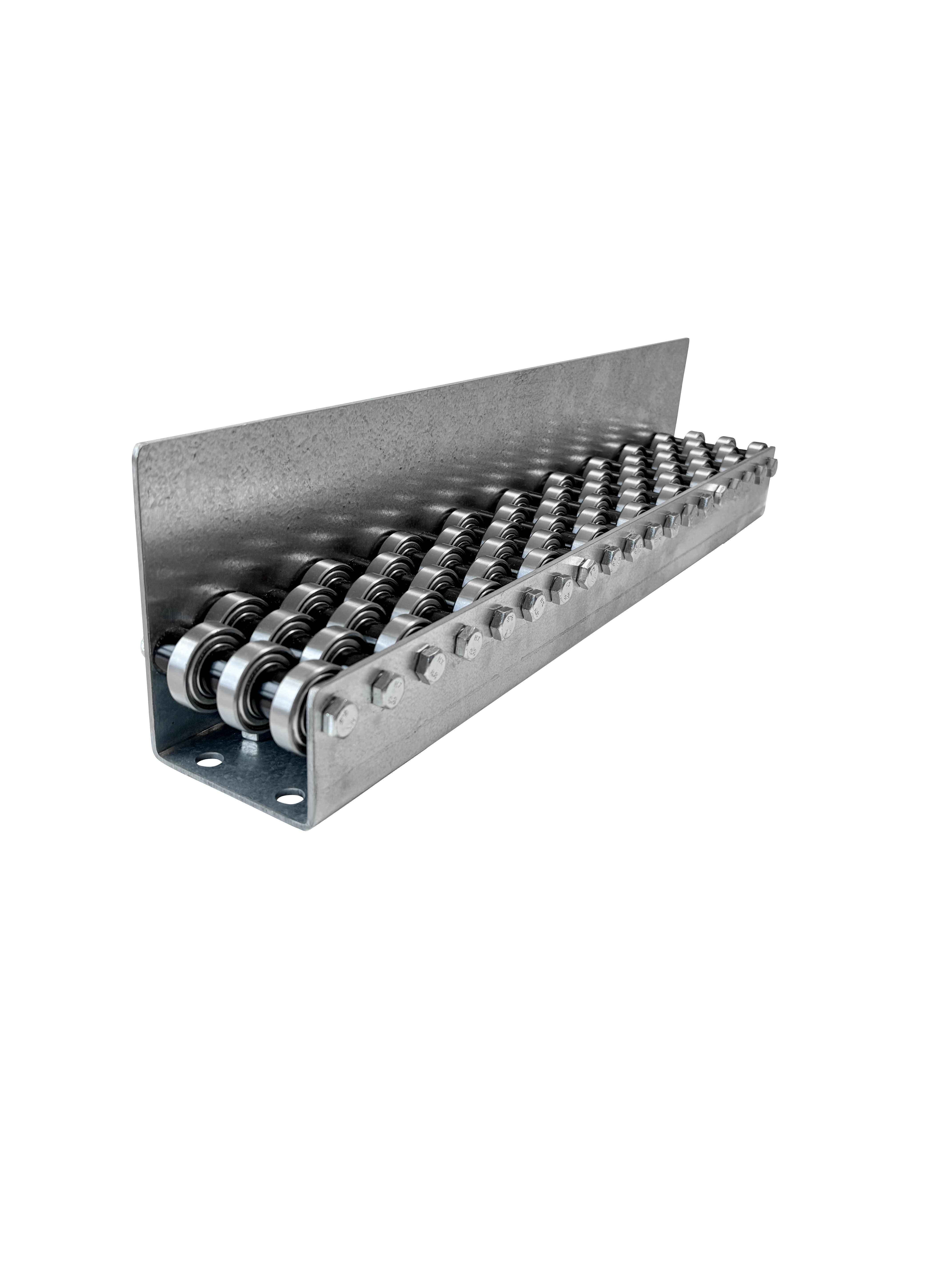

Heavy-Duty Roller Conveyors | Medium Loads

Accessories Heavy-Duty Roller Conveyors | Medium-Weight Loads

Heavy-Duty Roller Conveyors | Heavy Loads

Accessories Heavy-Duty Roller Conveyors | Heavy Loads

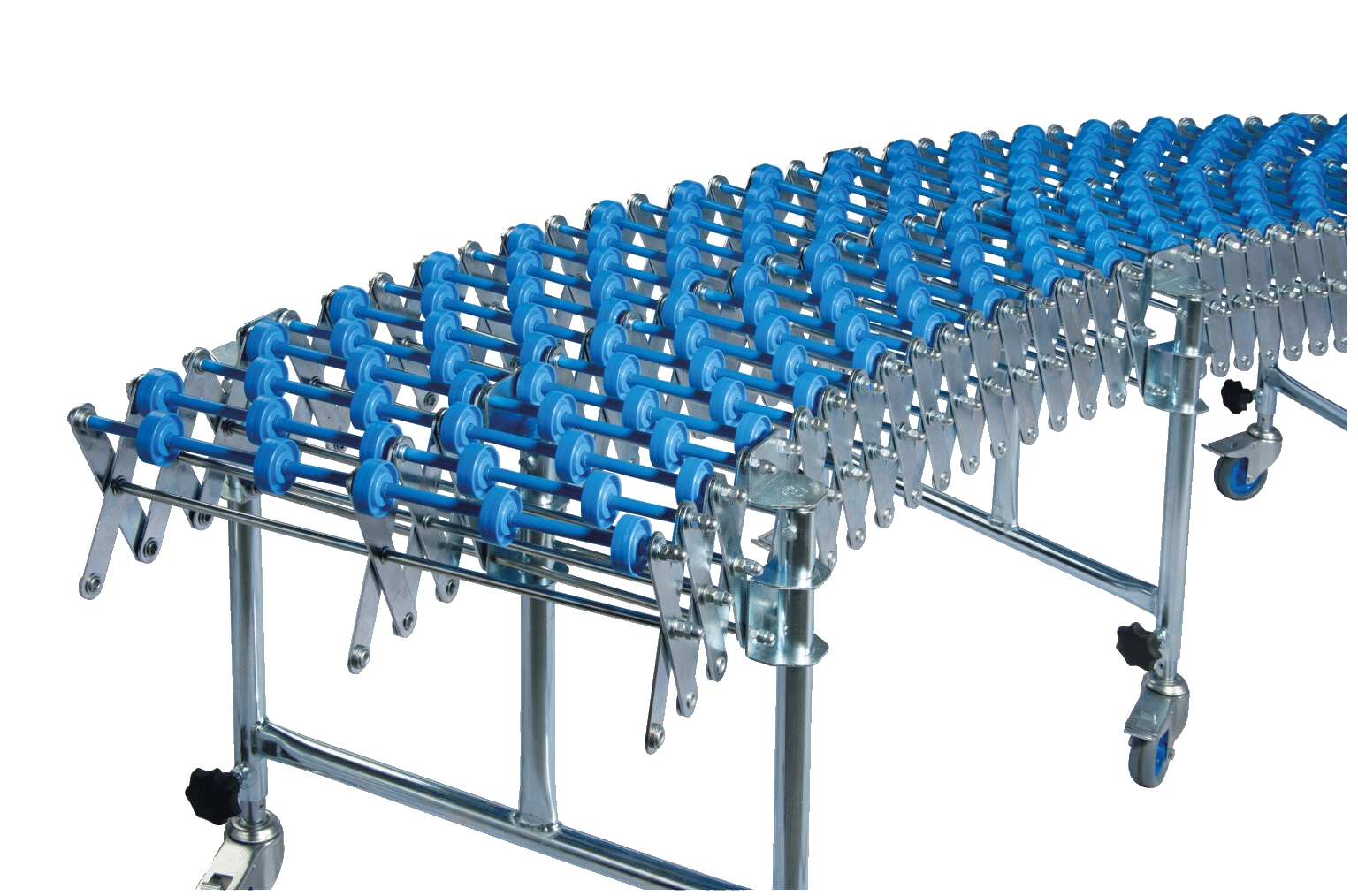

Scissor Roller Conveyors

Accessories Scissor Roller Conveyors

Conveyor Rollers up to 50 kg

Conveyor Rollers up to 200 kg

Conveyor Rollers with Flange

All-Way Rollers

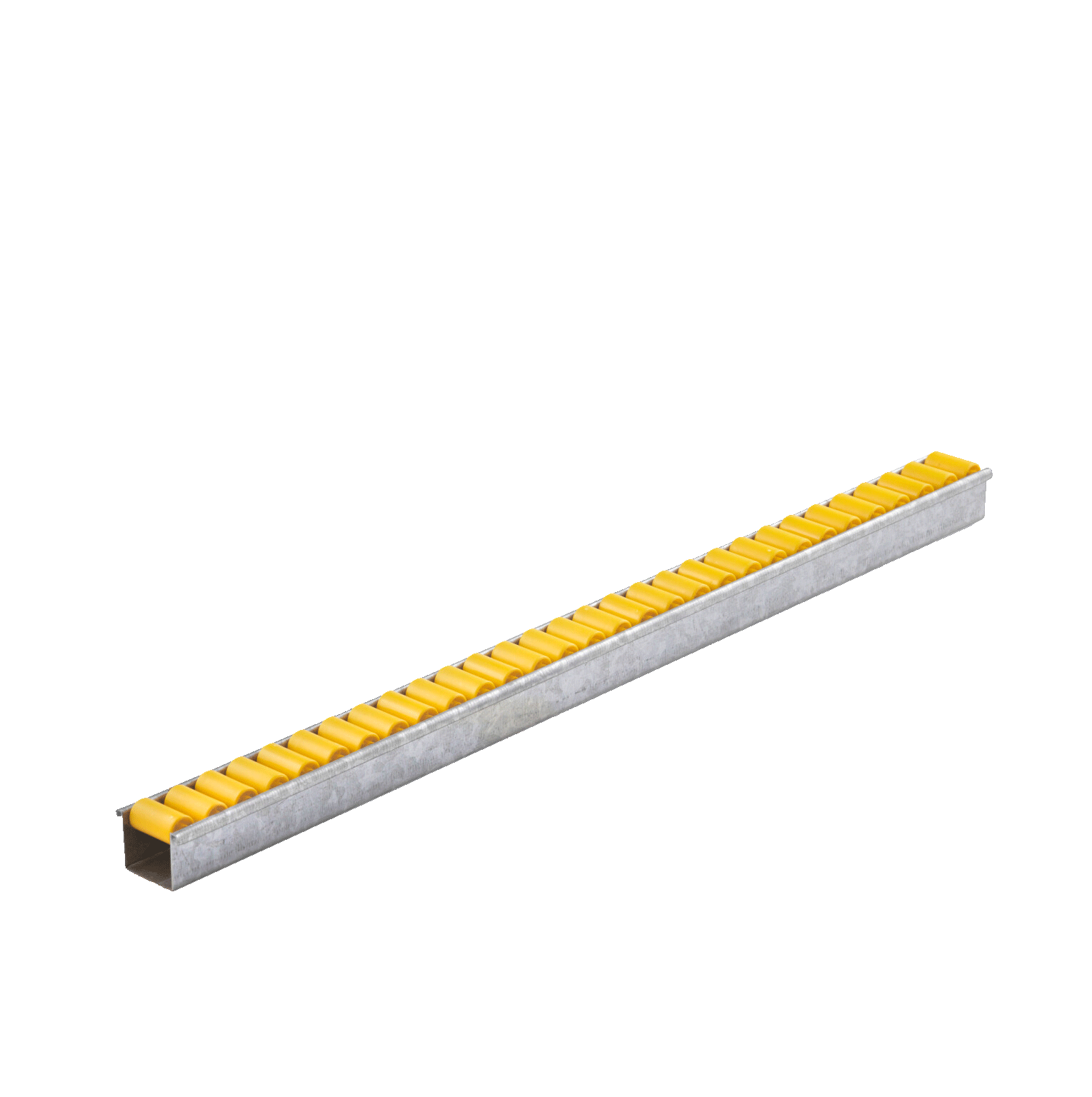

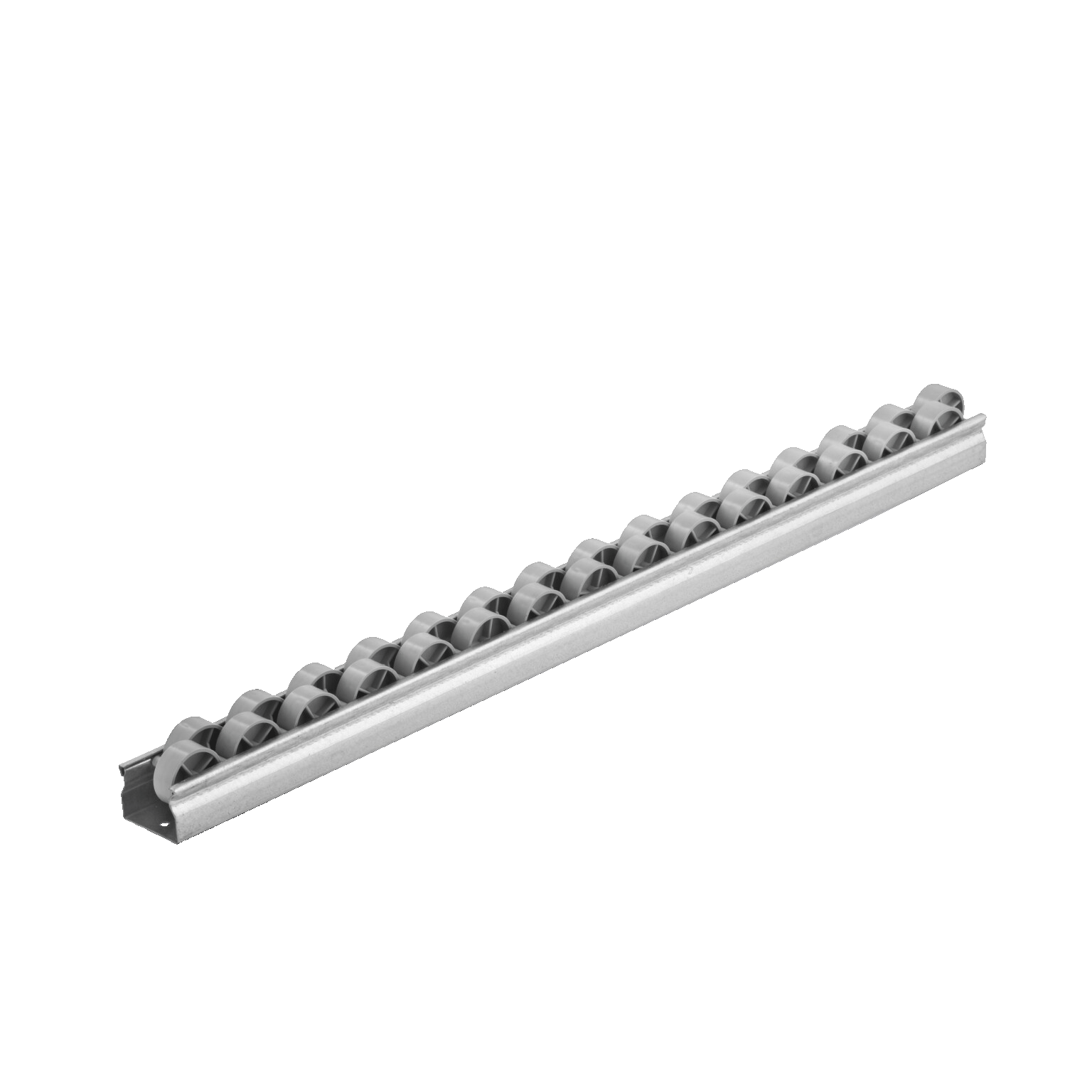

Mini Roller Tracks

Standard Roller Tracks

XL Roller Tracks

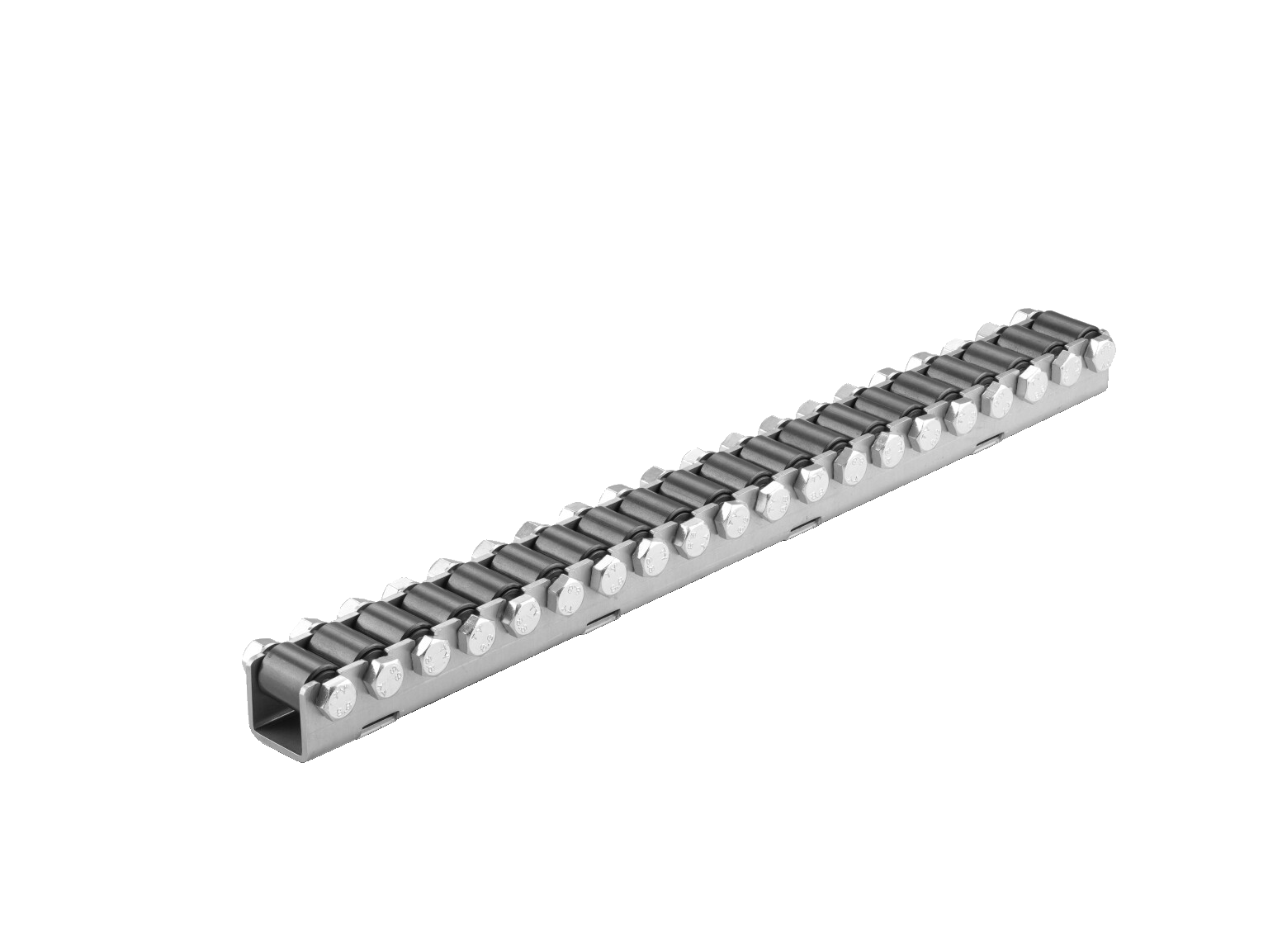

Heavy-duty Roller Tracks

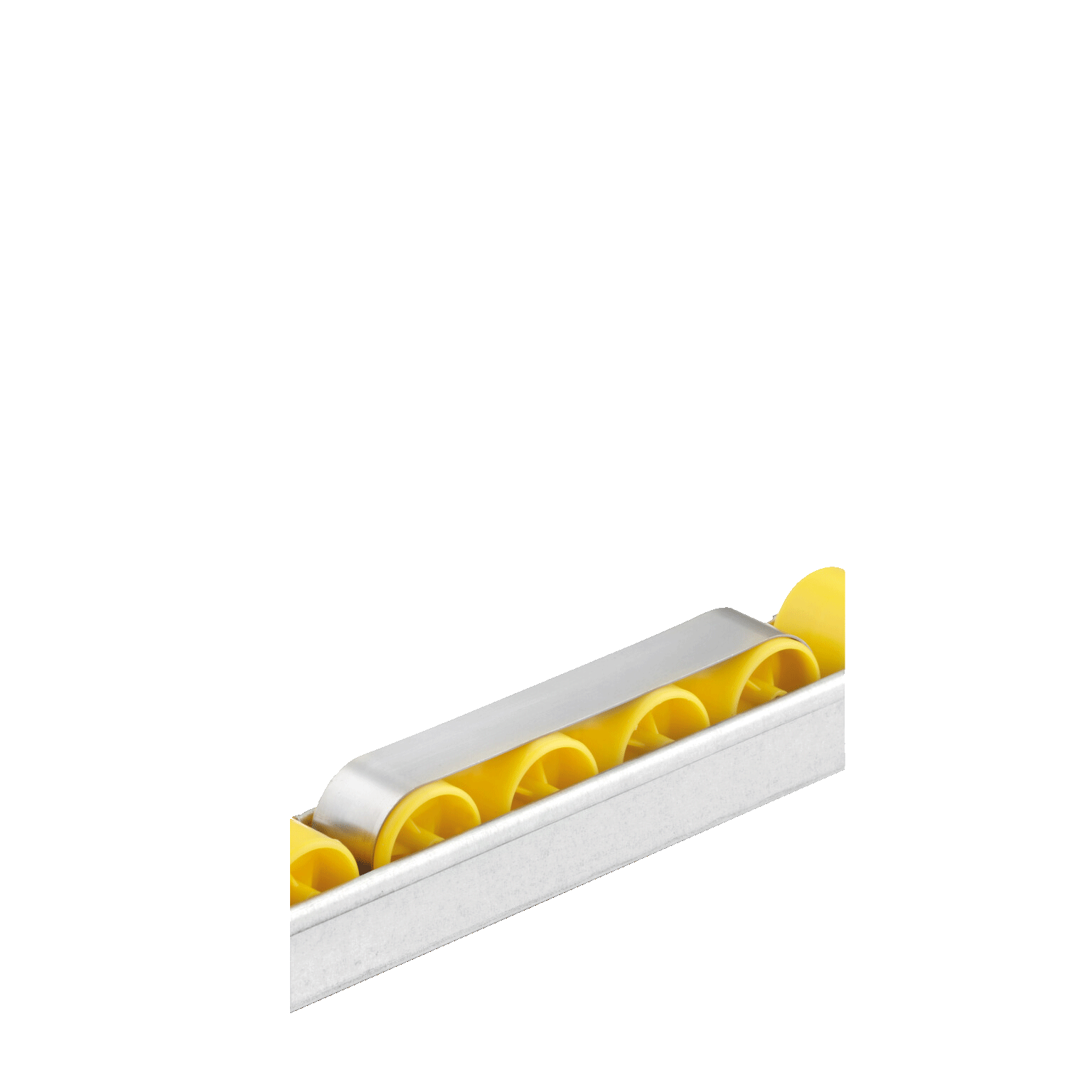

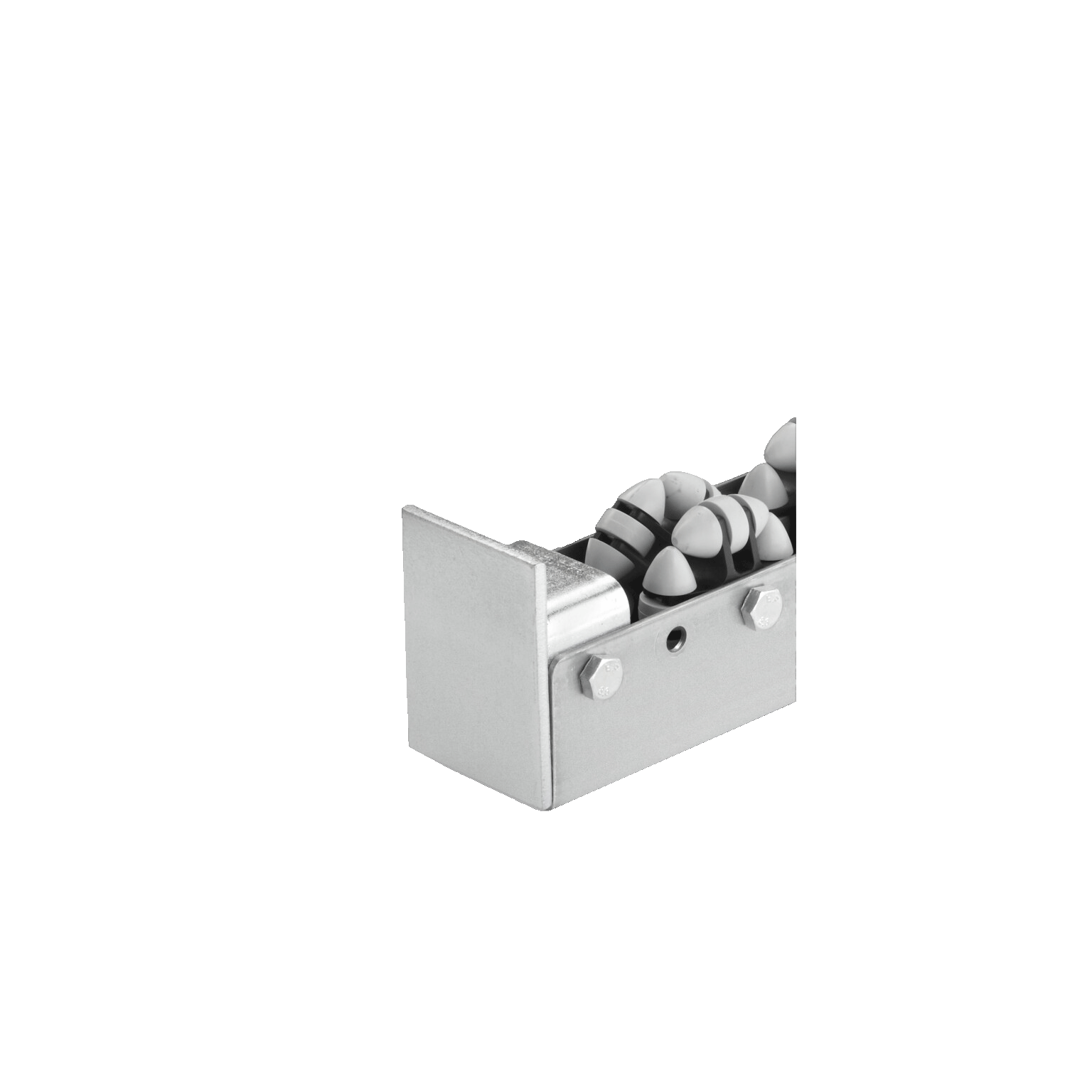

Accessories Roller Tracks

Zeus-Rollschienen

Universal Roller Rails

Accessories Universal Roller Rails

Colli Roller Rails

Accessories Colli Roller Rails

Roller Rails for Pallets

Accessories Roller Rails for Pallets

Heavy-Duty Roller Rails

Accessories Heavy-Duty Roller Rails

All-Side Roller Rails

Accessories All-Side Roller Rails

Ball Roller Rails

Slewing Rings

Rotary Joints

Durchlaufregale

Wikilogistics.ch defines transport technology as an umbrella term for conveyor and traffic technology. While traffic technology deals with various modes of transportation, conveyor technology—more relevant in this context—focuses on "in-plant transportation using continuous or discontinuous conveyors." Continuous conveyors handle the management and allocation of storage spaces, essentially functioning as the planning component. Discontinuous conveyors, on the other hand, include devices like forklifts—machines that pick up, transport, and deposit loads, moving them from point A to point B.

In our online shop, you’ll find everything you need for conveyor systems designed to optimize continuous workflows. For in-plant transport, durable roller tracks are ideal for flow racks or use in conveyor technology. Roller conveyors, on the other hand, are commonly used to link two workstations. They are employed, for example, in the sorting, distribution, and storage of unit loads. Available in various usable widths and conveyor lengths, they come in both powered and non-powered versions. Depending on their design, they can even be flexible and/or portable—adjustable in width or length, or even completely movable from one area of a facility to another. This makes them easily adaptable to specific applications.

If roller conveyors are no longer sufficient, conveyor systems can be supplemented with material support stands. This allows for flexible design and expansion, making the most of available space, even in smaller areas. Additionally, we offer slewing rings for comprehensive equipment setups, which provide a simple connection between the vehicle frame and the bogie. These feature two ball rows, ensuring wear-resistant power transmission and a longer service life.

To fully equip your conveyor system, our online shop also offers a wide selection of high-quality wheels and rollers. For the swift and secure transport of particularly sensitive and lightweight goods, we provide specialized conveyor rollers and omnidirectional rollers. Made of high-quality plastic, they can move goods in all directions on conveyor systems, ensuring smooth operation. These are especially suitable for roller tracks. Our product range also includes ball transfer units with housings made of steel sheet or stainless steel, recessed housings with threaded studs, or heavy-duty designs. Conveyor systems with ball transfer units made from solid steel material can handle loads of up to 1,500 kg. For applications with very low installation heights, we recommend ball transfer units with recessed steel housings and flange mounting.

Our range is rounded out with high-quality conveyor rollers, available in plastic or steel in our online shop. When used in roller conveyors, the combination of a slight incline with the rolling dynamics allows packages, storage bins, or even components to move forward using only gravity. To ensure smooth rotation, our rollers are equipped with high-quality ball, deep-groove ball, or plastic bearings.

For heavy-duty transport, steel conveyor rollers are the ideal choice. Depending on the version, they can support loads of up to one ton, making them suitable for pallet transport. They are also available in stainless steel versions and with various coatings, making them versatile for different types of conveyed goods.

When it comes to moving heavy loads on smooth surfaces, heavy-duty wheels and casters are the ideal solution. They can support weights of up to 10 tons. During the design process, we placed particular emphasis on durability. The swivel housings of these casters are equipped with sealed axial deep-groove ball bearings and tapered roller bearings, ensuring exceptional stability against shocks and impacts. The housing head is secured with a heavy central bolt for added strength and reliability.

These wheels and casters can even be used under extreme conditions. Depending on the material, they can operate in temperatures ranging from -100°C to +600°C (e.g., gray cast iron and solid steel) or offer high chemical resistance (e.g., gray cast iron).

Conveyor technology should not only meet the current needs of a business but also be designed with the flexibility to adapt to future requirements. This proactive approach helps minimize the need for costly and time-consuming retrofits or even the replacement of entire systems.

A modular design can provide the solution, allowing individual components or modules to be easily added or replaced without disrupting overall operations. The benefits are clear: businesses can respond flexibly to changes, whether it’s expanding production capacities, introducing new products, or adapting to shifting market conditions. Scalable conveyor technology thus becomes a strategic tool for securing a competitive edge.

Our modularly designed solutions not only enable seamless expansion but also the optimization of processes. We provide our customers with scalable, efficient, and cost-effective solutions. In an era where flexibility and adaptability are critical success factors for businesses, the importance of scalable systems continues to grow.

As a trusted provider for thousands of SMEs in Germany and across Europe, we demonstrate to our customers that investing in scalable systems is not only a long-term strategy but also a remarkably smart decision. Companies that prioritize scalability from the outset lay the foundation for a successful future in an ever-changing business environment.

In today’s energy crisis, energy and cost efficiency have become key requirements for drive technology, alongside reliability. This makes non-powered conveyor systems an increasingly attractive option. Conveyor lines designed for transporting goods can also play a significant role in automation solutions. TORWEGGE offers solutions in this area, such as roller conveyors or (pallet) roller tracks, tailored to customer requirements.

Non-motorized conveyor systems are cost-effective right from the start and require minimal maintenance. Damaged rollers can usually be replaced easily and at a low cost.

Gravity, a free and highly reliable force, is another advantage. For transporting goods, a small, adjustable incline on the conveyor line is often sufficient, depending on the weight of the items. In some cases, it can also be beneficial for employees to manually initiate the movement of goods, depending on the product being handled.

Conveyor systems consist of a wide range of rollers, wheels, roller conveyors, and tracks that efficiently streamline the transport of your goods. At TORWEGGE, you can choose from an extensive selection of conveyor technology and accessories or order custom-made solutions tailored to your needs.

Roller tracks are ideal for the efficient and demand-oriented transport of various goods. Our range includes everything from small roller strips for flow racks and lightweight goods to heavy-duty and pallet roller tracks. Our versatile conveyor rollers are used in a variety of transport solutions, primarily in roller tracks or flow racks. Our product lineup features numerous designs and weight classes. Additionally, our slewing rings serve as connection elements for transferring rotational movements, such as swiveling the front axle on the drawbar of a truck trailer. Our solutions meet the diverse demands of transporting goods of all sizes and weights.

If you can’t find the right part, we also offer customized solutions that adhere to the highest quality standards—quickly, innovatively, and at attractive prices. Browse our online shop and benefit from our extensive experience in conveyor, transport, and handling technology. Explore our wide selection of wheels and rollers to make your transport systems even more efficient.