1 Optimization of order picking at Festool

– effective filling of empty systainers

Use case:

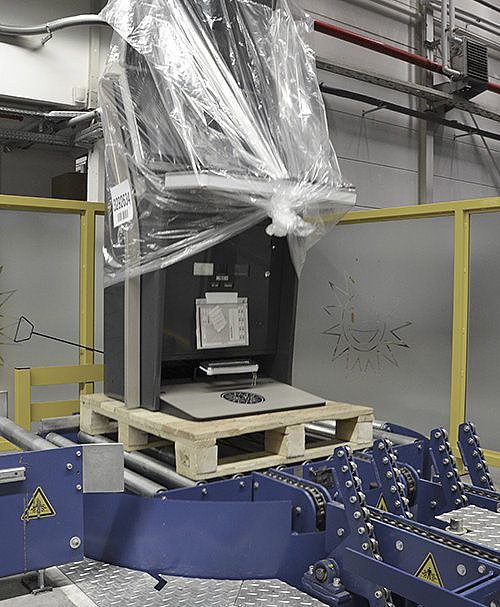

Material flow in power tool assembly

New buildings and production halls bring new challenges. This was also the case at Festool GmbH, which built a new hall in Weilheim to assemble its power tools. Here, the power tools are to be packed into empty Systainers after assembly. The challenge: a material flow solution that is as cost-effective and back-friendly as possible, while also being compatible with the somewhat unstable and uneven chipboard pallets used to store the gray boxes.

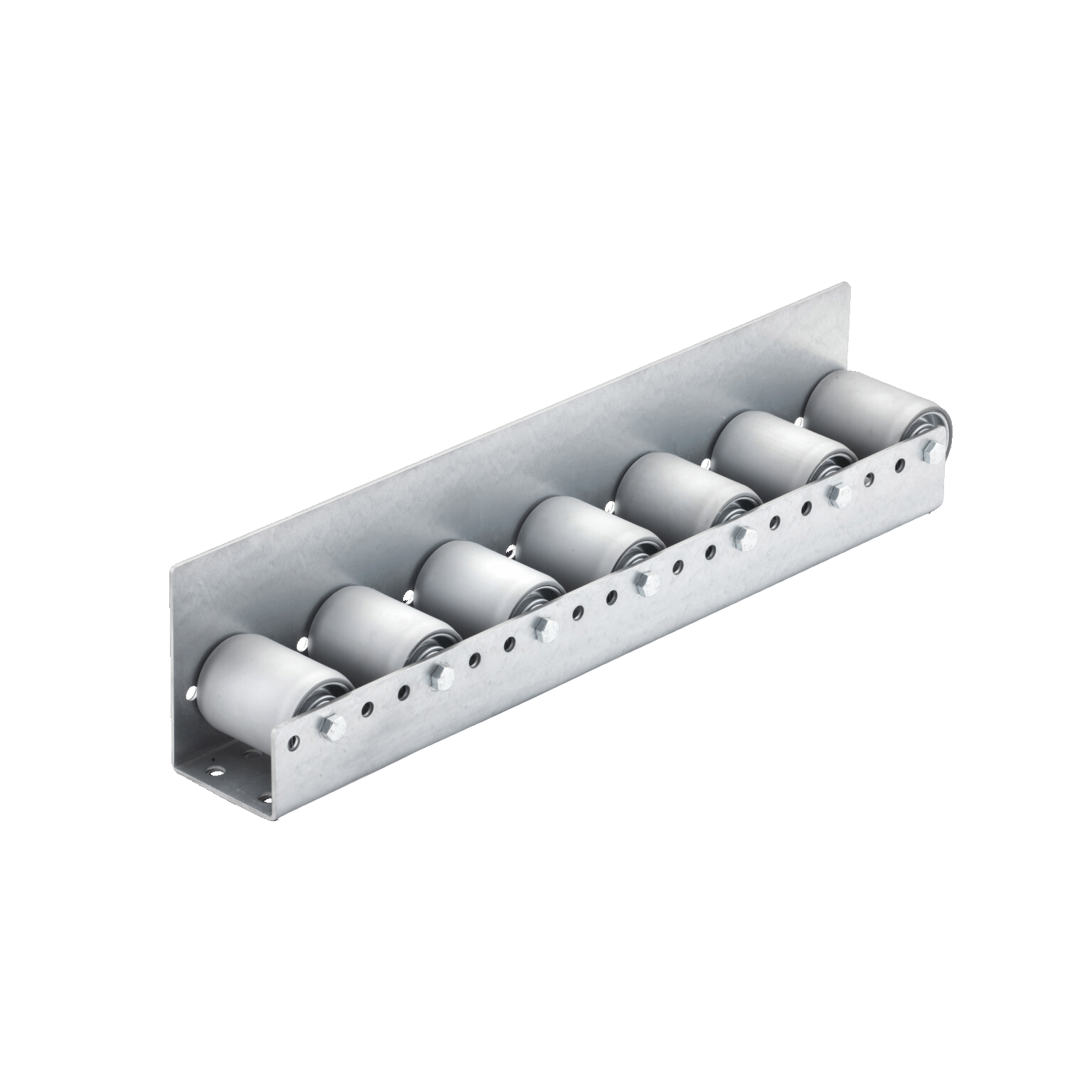

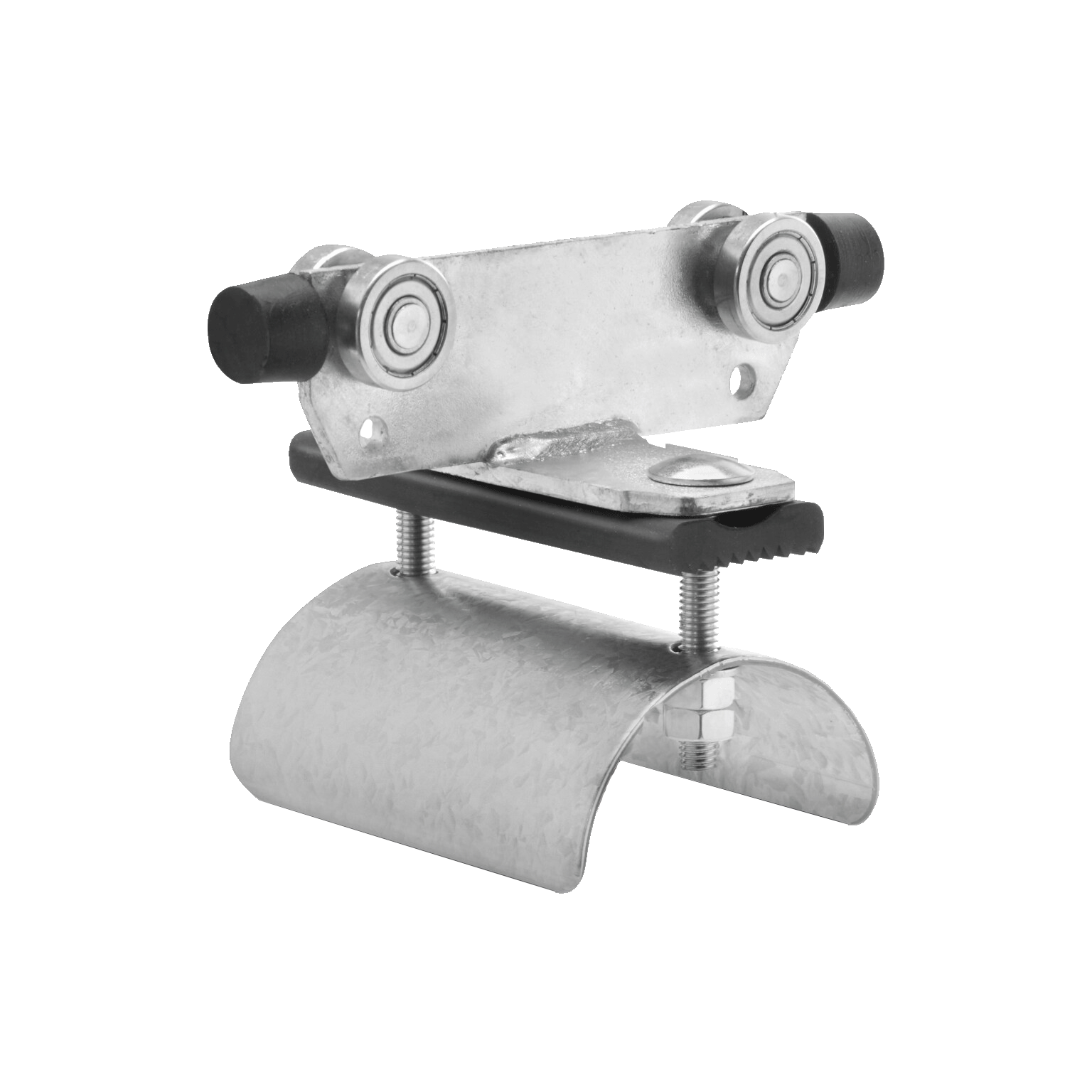

The TORWEGGE solution: a conveyor system consisting of roller tracks with offset rollers

After Festool explained the area of application, a brief consultation phase and the dispatch of some sample rails, we designed a conveyor system that can be operated with little effort, is easy on the back and enables a smooth material flow. The roller rails at Festool were attached to 28 assembly islands on the hall floor. Offset rollers were installed as conveyor rollers. For picking the power tools, seven automated guided vehicles (AGVs) move standardized stacking boxes, so-called Systainers, through the 6,500 square meter hall. At the assembly islands, the AGVs transfer the empty Systainers on a chipboard pallet to the roller rails. Specialists fill them with the assembled tools and can pull the pallet to the next position on the roller tracks using a drawbar. The force required to move the Systainer on the rails is low, as the rollers form more contact surface for the transported goods due to their staggered arrangement and narrower pitch, resulting in good running behavior. The loaded Systainers are then transferred back to the AGV - the next pallet with empty Systainers is already waiting at the start of the roller tracks.

The special feature: conveyor rollers in the corporate design color

Festool has an expressive corporate identity and attaches great importance to the fact that the corporate color - the lush green - is reflected in the entire product range and also in the buildings and work clothing. To ensure that the new assembly hall also shines in Festool CI, as many elements as possible were to be installed in the corporate colors.

We therefore offered an individual solution consisting of roller rails and conveyor rollers in the matching RAL color of Festool GmbH and had these manufactured especially for our customer.

2 Optimization of the production line at adp Gauselmann

A new challenge

After the East Westphalian gaming machine manufacturer expanded its configuration area with an additional assembly hall, it was looking for a suitable system for its internal material flow. A fully automated transport system was required that would cover all intralogistics requirements as cost-effectively and risk-free as possible and also guarantee a smooth connection to the logistics service provider's conveyor systems.

Holistic assembly management system

With an integrated assembly management system, we then presented a future-proof concept that significantly simplifies the assembly work and transportation of the gaming machines.

In the first phase of the project, our sales representatives made regular visits to gain a precise picture of the intralogistics challenges on site. This was followed by comprehensive consultation meetings. During these meetings, the project managers also presented drawings, sketches, photos and videos of reference systems and reported on their experiences with the solutions. In this way, the advantages and disadvantages of the different systems became clear.

Klaus Lange, Head of End Device Production, adp Gauselmann GmbH

“Thanks to the close contact in the past, there was already a lasting basis of trust that we were able to build on for this extensive project.”

“We needed support from a proven expert in the field of intralogistics to find the right solution for the optimum material flow.”