Optimising your material flow - safely and efficiently!

Welcome to TORWEGGE conveyor elements!

For more than 40 years, we have been passionately dedicated to the optimisation of internal material flow. Originally, we manufactured roller and roller conveyors for the furniture industry. Today, we design components for conveyor technology as well as customised conveyor systems for the internal logistics of numerous industries.

1 Idlers

TORWEGGE offers you a wide selection of gravity and powered conveyor rollers consisting of high-quality components such as tubes, axles, bearings and bearing bases. Our powered rollers also have drive elements that optimise the transport of your goods.

Our product range includes standard castors, gravity castors and powered castors in a wide variety of designs. We divide the powered rollers into accumulation/friction rollers and rollers with fixed drive, whereby we use chain, toothed or round belts. These drive elements ensure efficient transport and optimum adaptation to your conveyor processes.

The selection of the right idler depends on the characteristics of your conveyed goods. We manufacture the rollers according to your specific specifications and requirements in order to support your workflow in the best possible way. We also offer special brake rollers to ensure a constant speed of your conveyed goods on the gravity conveyor.

Discover the wide range of options at TORWEGGE and find the perfect solution for your conveyor technology.

Insight into our idler production

8 steps to the right idler

- Determine the weight and dimensions of the conveyed goods.

- Are there any special environmental influences, such as moisture, dust or extreme temperatures?

- Should the idlers be driven? If so, how (belt or chain) and at what conveying speed?

- Choice of pipe material (plastic, aluminium, steel or stainless steel) according to weight and requirements.

- Choice of installation length and diameter of tube and shaft. This has a particular influence on the load capacity.

- Selection of the bearing design and type, according to the requirements for load capacity, environmental influences and precision.

- Choice of axle end machining. How should the idlers be mounted? A fixed mounting (external or internal thread) ensures an approx. 2/3 higher load capacity.

- Does the material to be conveyed require a special coating or accessories?

You can rely on our experience when choosing your idlers. We will be happy to supply you with a customised solution.

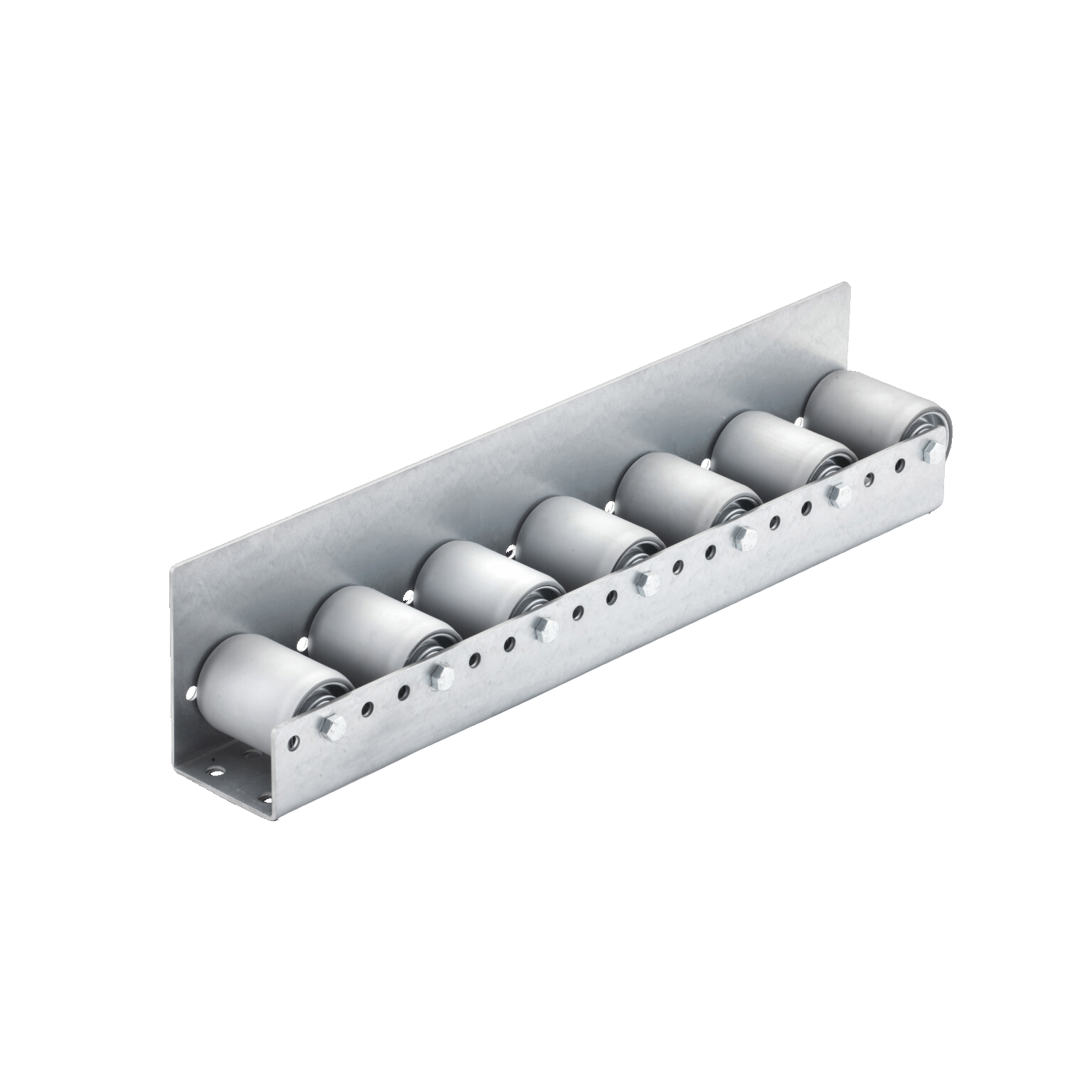

2 Roller Conveyors

Our gravity roller conveyors

Our gravity roller conveyors have a gradient of at least 2 per cent. We produce small and light roller conveyors as well as very heavy-duty versions and flexible scissor roller conveyors. You can choose between different roller pitches, effective widths and track lengths. Our roller conveyors can also be flexibly extended and customised to your requirements with the appropriate accessories. We also have powered roller conveyors, in our portfolio - please contact us!The advantages of a gravity roller conveyor

- No energy = lower costs

- Quiet transport

- Cost-effective replacement of individual rollers when worn

- No maintenance costs as no motorisation is required

- Customisable speed of movement thanks to individually adjustable gradient

- Direction of transport can be changed

2 The choice of Roller Conveyor

Finding the Right Roller Conveyor

- Determine the conveyor type based on the weight of the goods: The dimensions and weight of your transported goods dictate the choice between a lightweight roller conveyor or a stainless steel roller conveyor for heavier items.

- Select the conveyor width based on the largest transported item: The roller conveyor should be wider than the transported goods, especially in curves, to ensure safe transport.

- Divide the smallest item length by 3 to determine roller spacing: The base of the transported goods must rest on at least three rollers to guarantee stable transport.

- Plan for supports: Supports should be installed every 1,500 mm to 2,000 mm, as well as at joints and curves, to ensure the stability of the roller conveyor.

- Ensure an even and sturdy running surface: The running surface for the goods must be even and sturdy to facilitate smooth transportation.

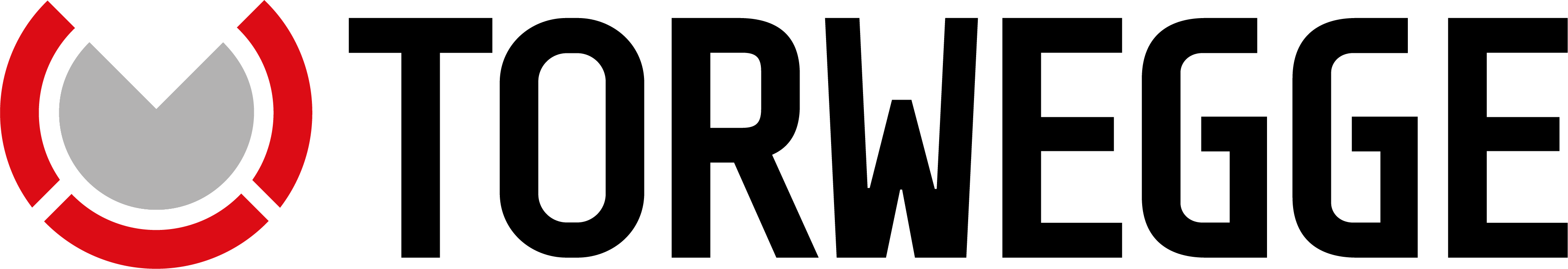

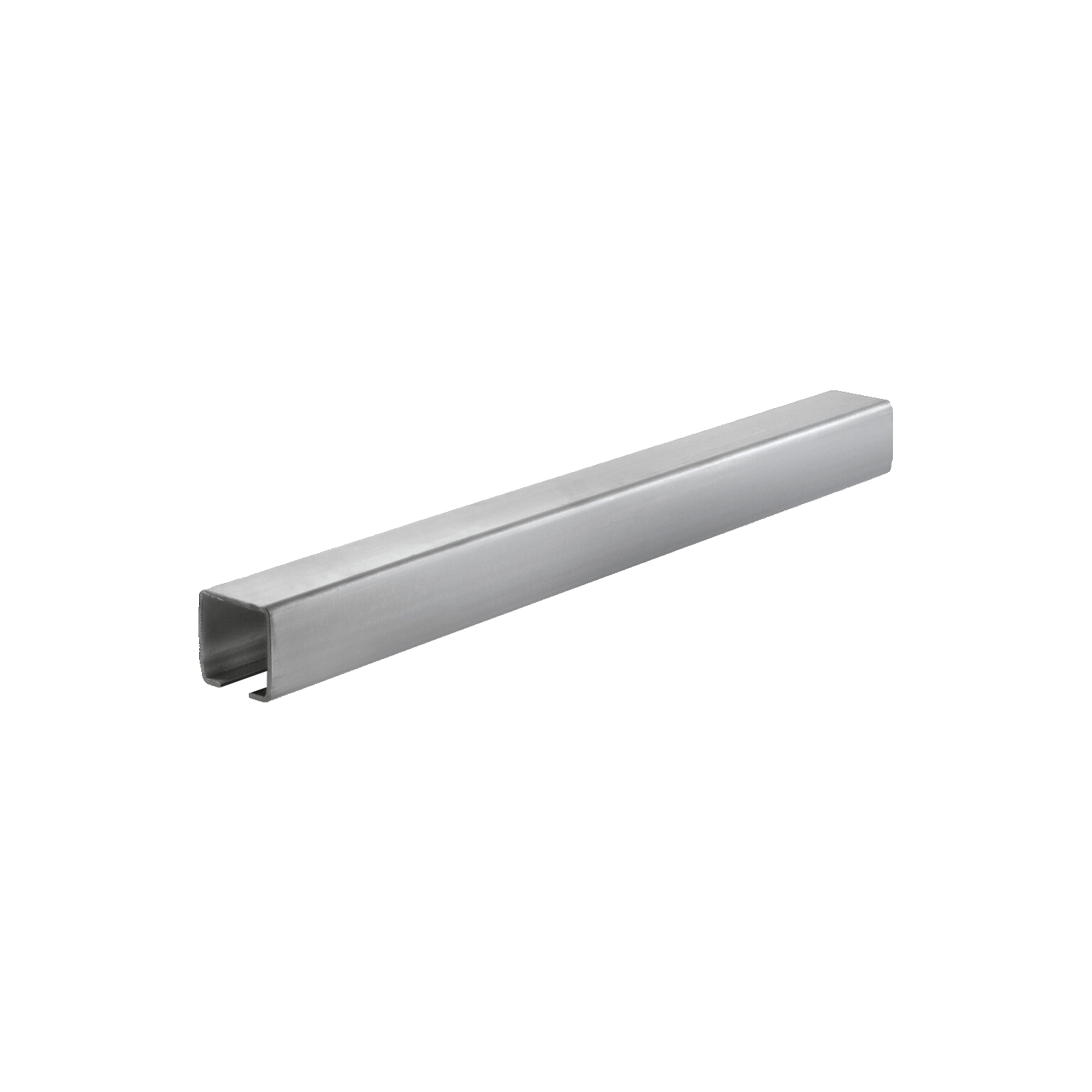

3 Roller Rails and Roller Tracks

Selection of Roller Rails and Roller Tracks at TORWEGGE

Roller Tracks

Roller tracks are ideal for lightweight goods such as small cartons or storage containers in flow racks.

- Plastic rollers: Available in standard versions or with flanged edges

- Diameter range: From Ø13 mm to Ø40 mm

- Variety of options: Including germ-free versions or models suitable for cold storage areast

- Customizable spacing: Different roller spacing configurations available

- Extensive accessories: A wide range of compatible accessories to meet your needs

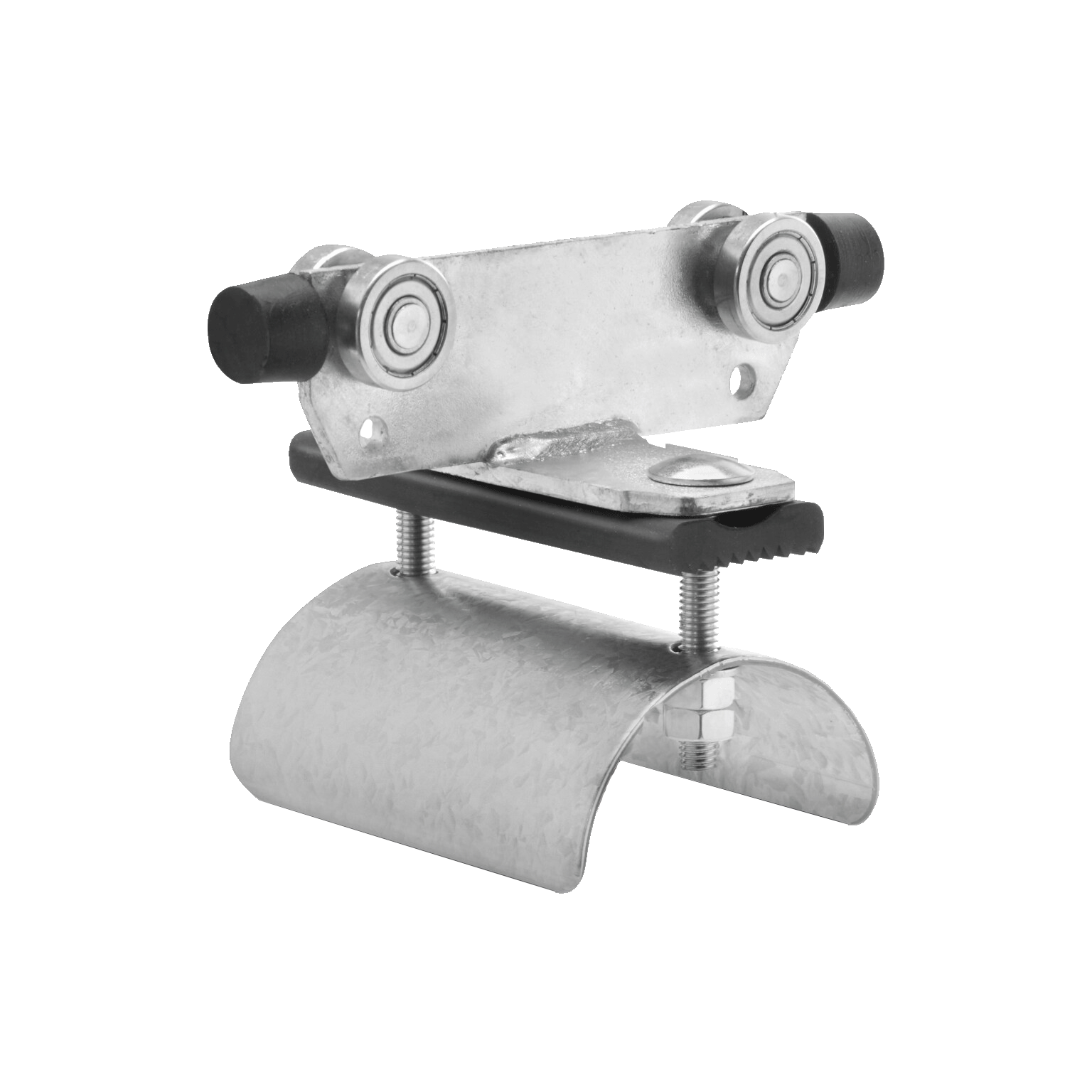

Universal and Colli Roller Rails

Omnidirectional and Ball Roller Rails

In addition to standard roller rails, TORWEGGE offers specialized omnidirectional and ball roller rails to meet your specific needs. These are particularly suitable when flat-based goods need to be transported, sorted, or rotated in various directions. Their use is ideal in industries such as automotive, packaging, wood, and furniture manufacturing. Omnidirectional roller rails can also be integrated into the main transport direction due to their higher rolling resistance in that configuration. While omnidirectional roller rails can support up to 40 kg per roller, ball roller rails can handle loads of up to 160 kg per roller.

- Flexible handling capabilities for light to medium-weight goods

- Variety of roller and ball roller options

- Extensive range of accessories and unparalleled versatility.

To ensure a smooth, stable, and consistent flow of your goods, they should always rest on at least three rollers.

Philosophy & Values

"At TORWEGGE, we prioritize quality, reliability, and sustainability. Our conveyor components are designed to enhance efficiency and safety in logistics. With precise manufacturing and tailored solutions, we meet the specific needs of our customers. Our commitment to advanced technology and customer-focused service is at the core of everything we do."

Working Approach & Customer Benefits

"At TORWEGGE, we collaborate closely with our customers to develop solutions that are both precise and efficient. Utilizing state-of-the-art technologies and continuous quality controls, we manufacture conveyor components that optimize logistics processes, enhance efficiency and safety, and reduce operational costs. Each component is designed to improve workflows and meet the specific needs of our customers."

Sustainability

"At TORWEGGE, sustainability is a key priority. A central aspect of our company philosophy is to reuse production waste as much as possible. Through innovative processes and technologies, we minimize waste and maximize resource utilization. In this way, we actively contribute to environmental protection while pursuing the goal of resource-efficient production."

Your Contact Person

Niklas Knappe is your personal point of contact for all matters related to TORWEGGE conveyor components.

Schedule an appointment now!

Niklas Knappe

Teamleader conveyor components

Tel.: +49 521 934 176 12

E-Mail: niklas.knappe(at)torwegge.de