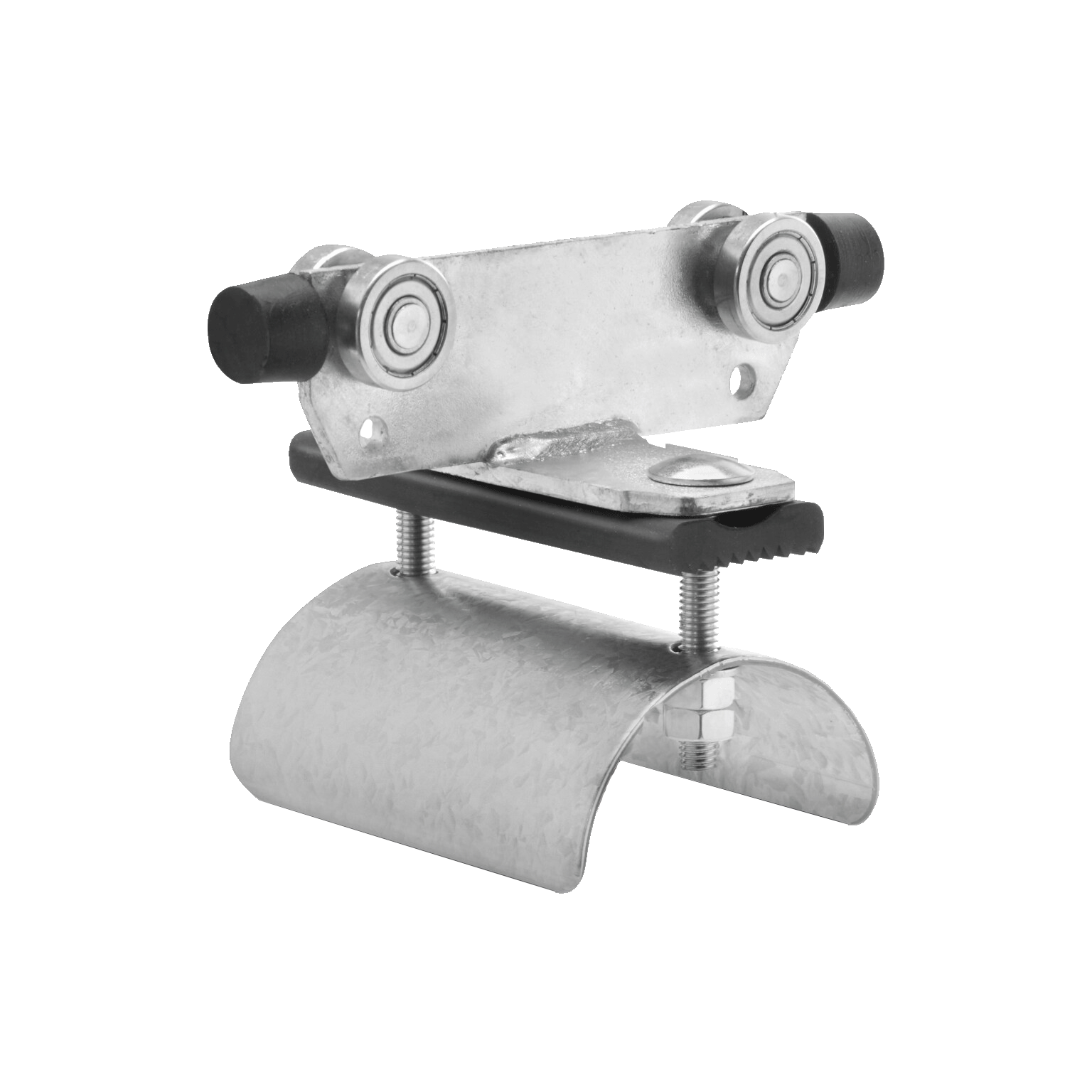

Move Heavy Loads with Solid Ball Transfer Units

In the industrial sector, ball transfer units are a benchmark in conveyor technology, offering maximum flexibility and the ability to move goods in all directions. Thanks to the small rolling balls within their housing, they operate with minimal noise and friction. However, protecting the internal ball bearings from deformation under excessive force can sometimes be a challenge.

Solid housing made from full material solves this issue, allowing ball transfer units to handle loads of up to 1,500 kg. Explore our TORWEGGE online shop today and find the perfect solution for your needs!

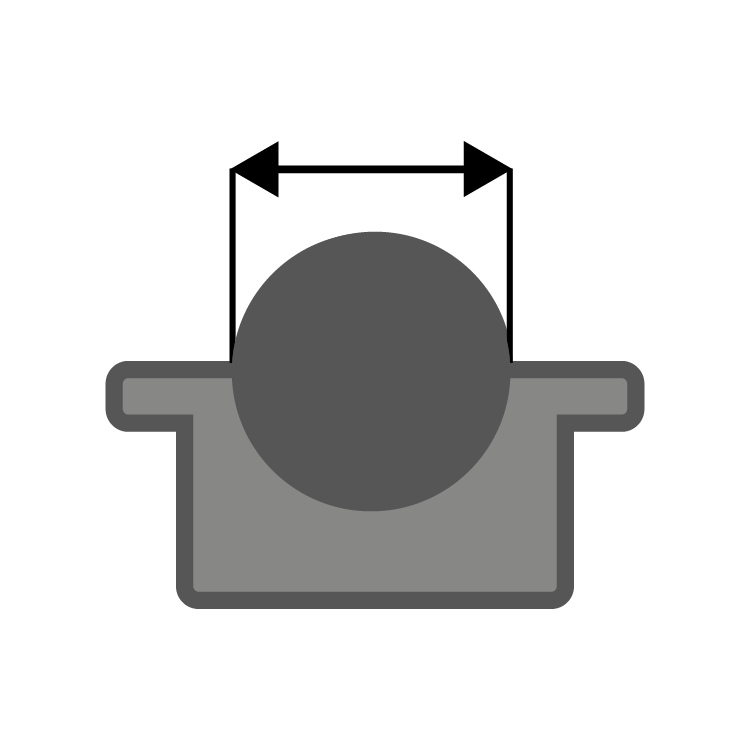

180 kg

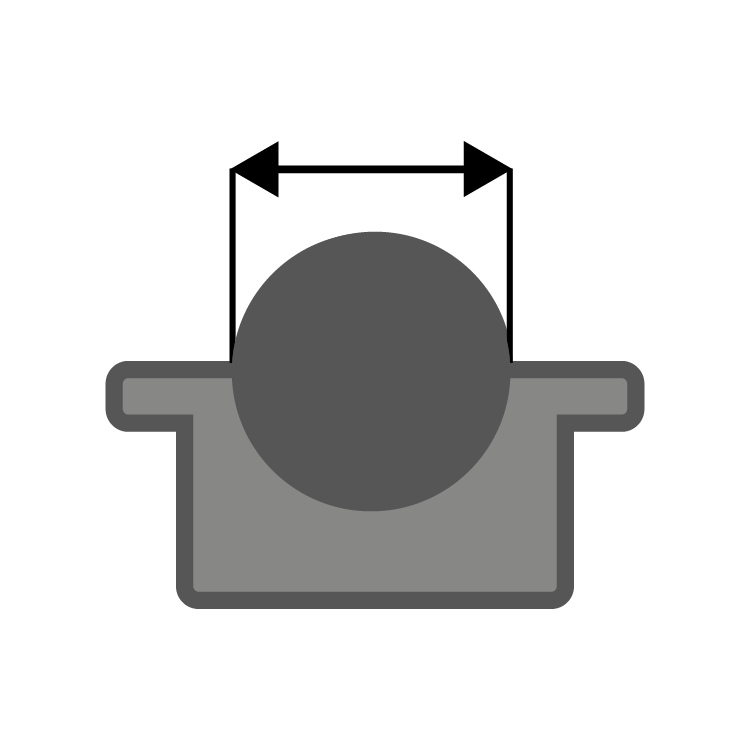

22,2 mm

36 mm

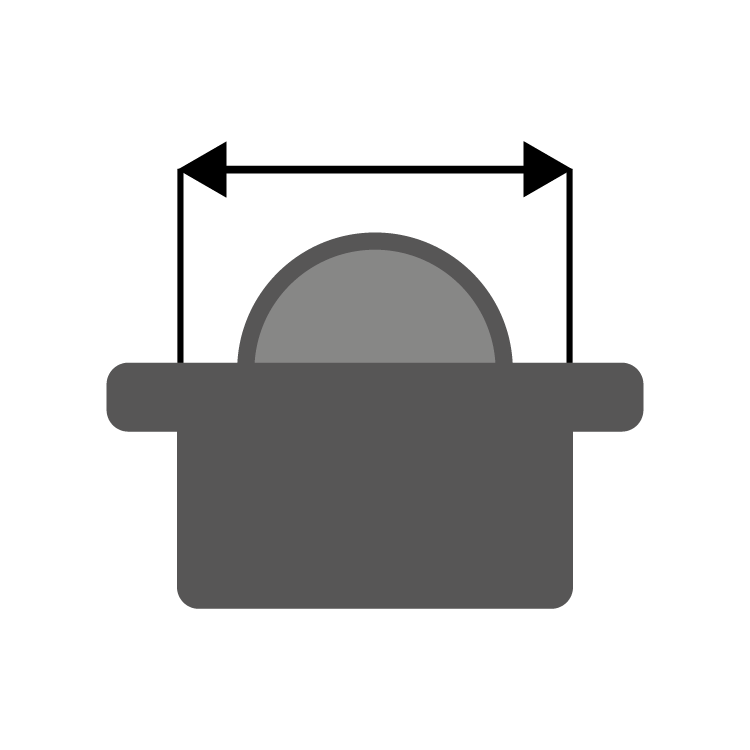

350 kg

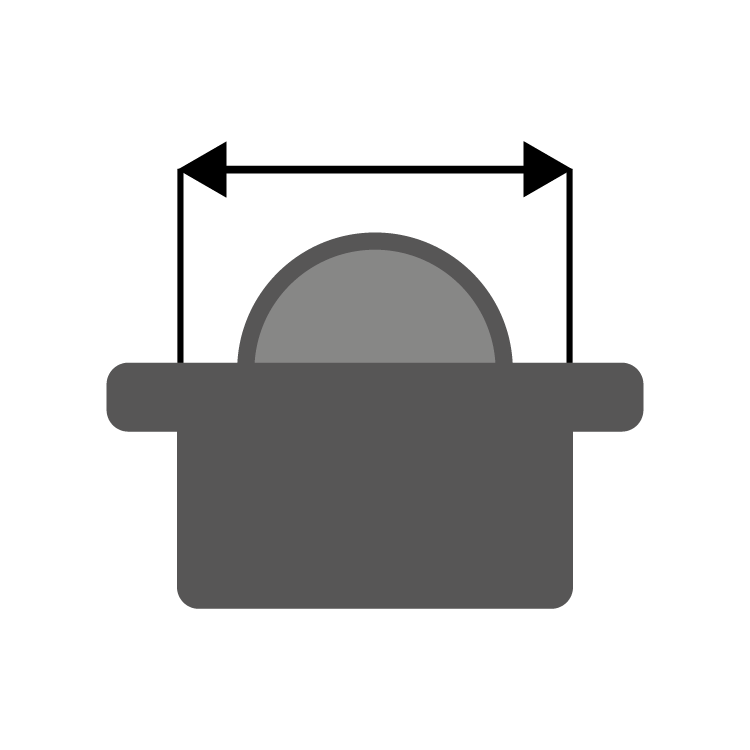

30 mm

45 mm

Extreme Load Capacity with Maximum Flexibility

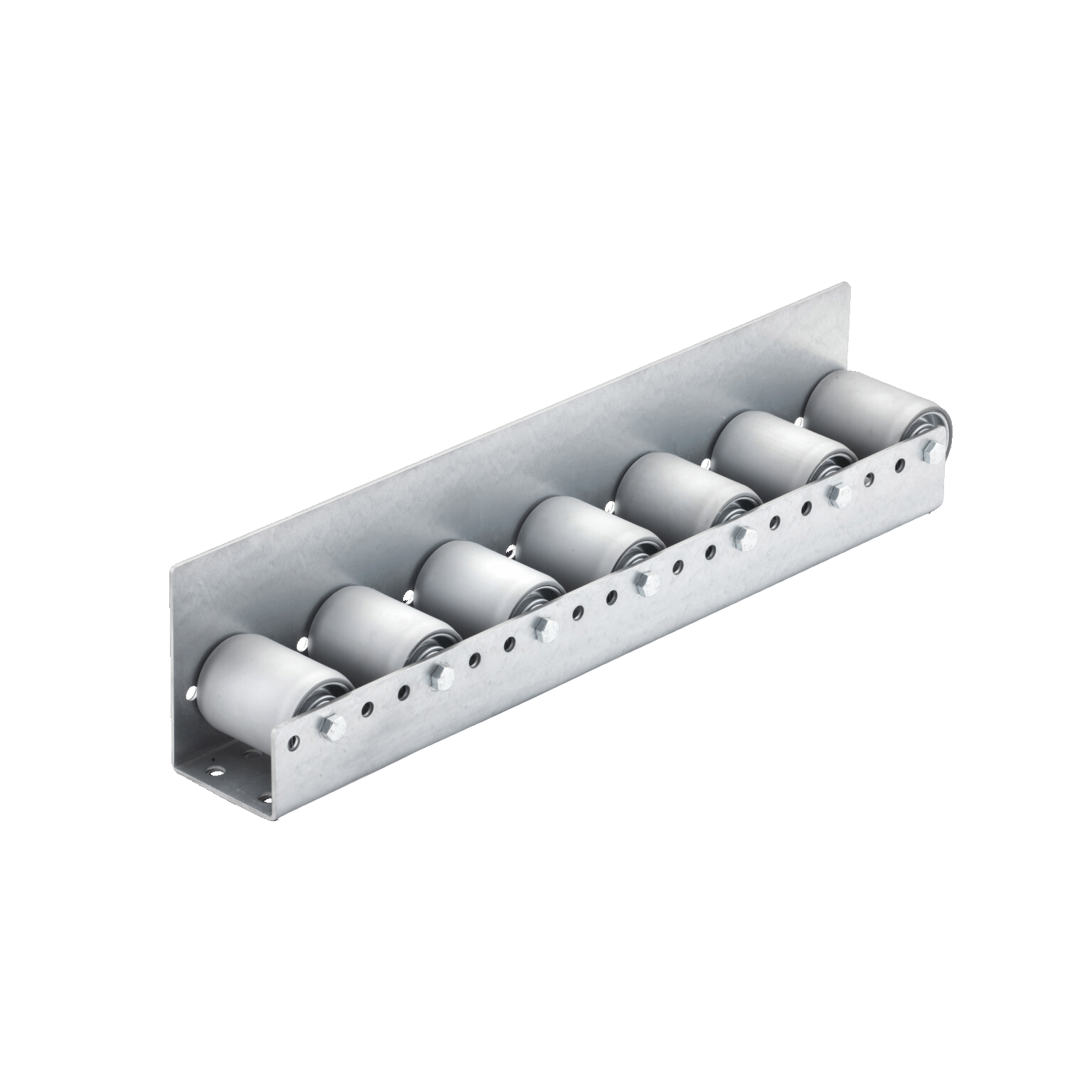

Thanks to the meticulous manufacturing of our ball transfer unit housings from solid steel material, they offer significantly higher load capacity compared to steel sheet housings. This allows you to effortlessly maneuver and rotate even larger loads without being confined to limited or straight transport paths.

For optimal use, these units can be installed into a rail or ball transfer table, which can also be fitted with caster wheels if needed, making them versatile across different applications. This setup not only reduces the physical strain on your employees but also helps prevent workplace accidents.

Even under impact loads from multiple directions, the robust solid material retains its shape with ease. However, please note that when mounted overhead, the load capacity can be reduced by up to 50%. Be sure to factor this into your calculations for safe and effective use.

Applications of Solid Ball Transfer Units

Ball transfer units made from solid material stand out for their high load capacity, making them ideal for areas where heavy loads need to be moved with maximum flexibility. In mechanical and plant engineering, for example, ball transfer units installed on worktables ensure that workpieces can be easily and precisely positioned. They are also widely used in conveyor technology, special-purpose machinery manufacturing, and the beverage industry. Their key advantage is the ability to push even heavy workpieces or goods in any horizontal direction, as well as effortlessly rotate loads.

The principle of ball transfer units is both simple and ingenious. The main rolling ball or load ball rests on several smaller support balls, which in turn roll within a support cup. A felt seal with a dirt outlet completes the design. This self-cleaning mechanism and compact construction make these units low-maintenance and durable.

The solid steel housing and balls made of steel or stainless steel are precisely engineered. This combination of high-quality materials and meticulous craftsmanship ensures that the rolling ball moves smoothly and effortlessly, even under heavy loads. This enables exceptional flexibility for moving heavy loads in any direction, a significant advantage across various industrial applications.

The robust housing prevents deformation of the support cup, reducing wear caused by increasing friction and ensuring the longevity and reliability of the units.

Choosing Between Different Rolling Balls

We offer our solid ball transfer units with rolling balls made of either steel or stainless steel. The primary advantage of stainless steel lies in its superior corrosion resistance, making it the better choice for damp or aggressive environments.

The housings for both variants are galvanized, ensuring durability and resistance to external influences, providing a reliable solution for your specific application needs.

Durable Design of Solid Ball Transfer Units at TORWEGGE

At TORWEGGE, we prioritize equipping our high-quality solid ball transfer units with comprehensive features that enhance their durability and functionality. Many of our models include an integrated self-cleaning felt seal and a dirt outlet to improve rolling performance and effectively prevent clogging.

As an alternative to this dirt management solution, we also offer ball transfer units with an extra-large dirt drainage screen, which replaces the sealing ring and supports the self-cleaning mechanism of the bearing.

Investing in cleaning mechanisms for your ball bearings pays off significantly in the medium to long term, ensuring consistent performance and extended service life for your equipment.

Buy Solid Ball Transfer Units from TORWEGGE

As a long-standing manufacturer of transport systems, TORWEGGE uses its expertise to provide you with the perfect product. Our range of ball transfer units, including universal ball transfer units and ball transfer units with threaded stems, ensures long-lasting efficiency, backed by our commitment to quality. Explore our extensive selection of conveyor and transport technology solutions to optimize your logistics and production processes.

If you have any questions or specific requests, we’re here to help. Contact us quickly and easily via our contact form—we look forward to hearing from you!