Optimize Your Overhead Conveyor System with High-Quality 90° Bends from TORWEGGE

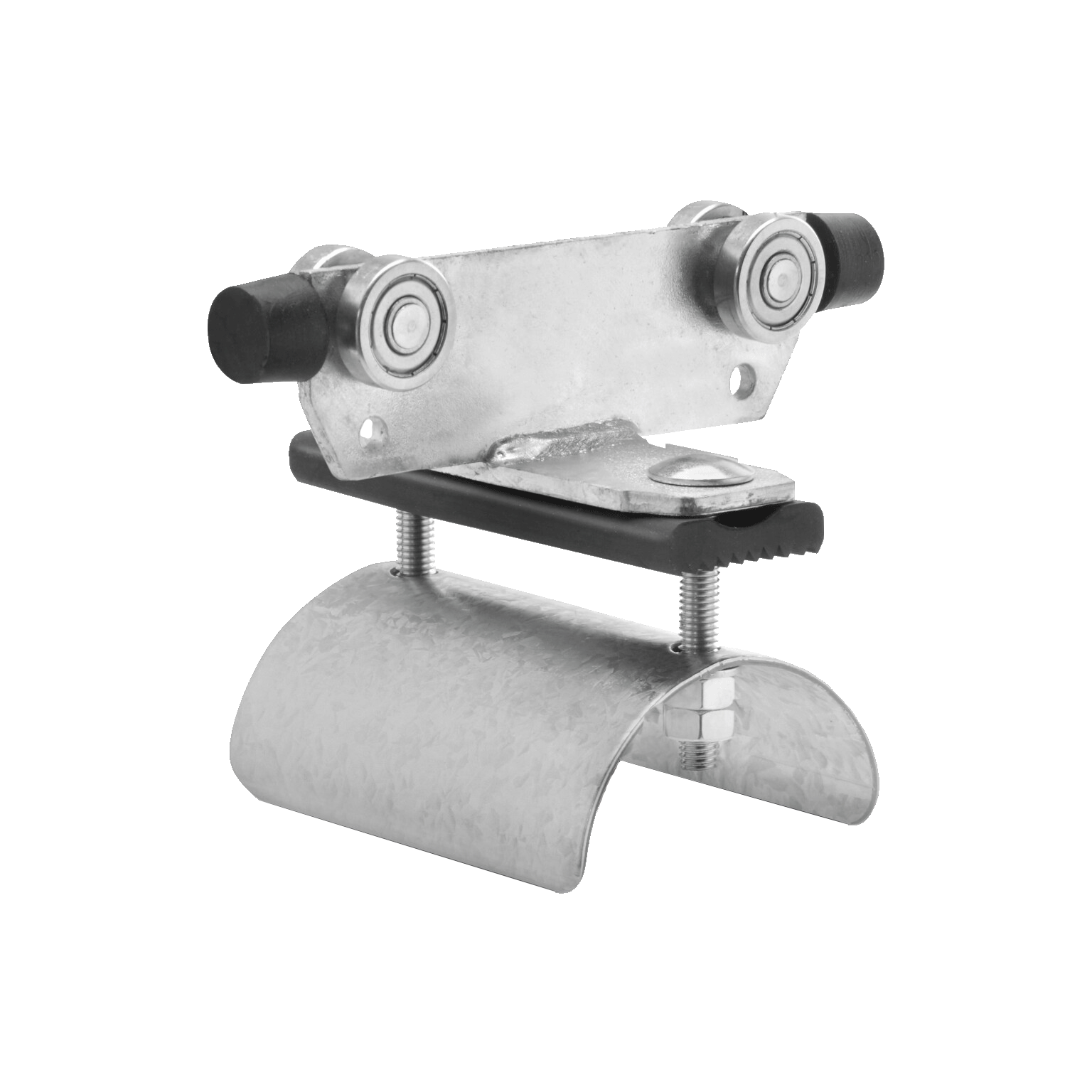

To ensure cables, hoses, and other loads are transported quickly and neatly at individual workstations, an overhead conveyor system is essential. The rail system must always be tailored to the spatial conditions of the workstations, making 90° bends just as important as classic C-rails. These bends allow the conveyor system to be routed in different directions or around corners seamlessly.

Visit our TORWEGGE online shop to find high-quality 90° bends for your customized overhead conveyor system!

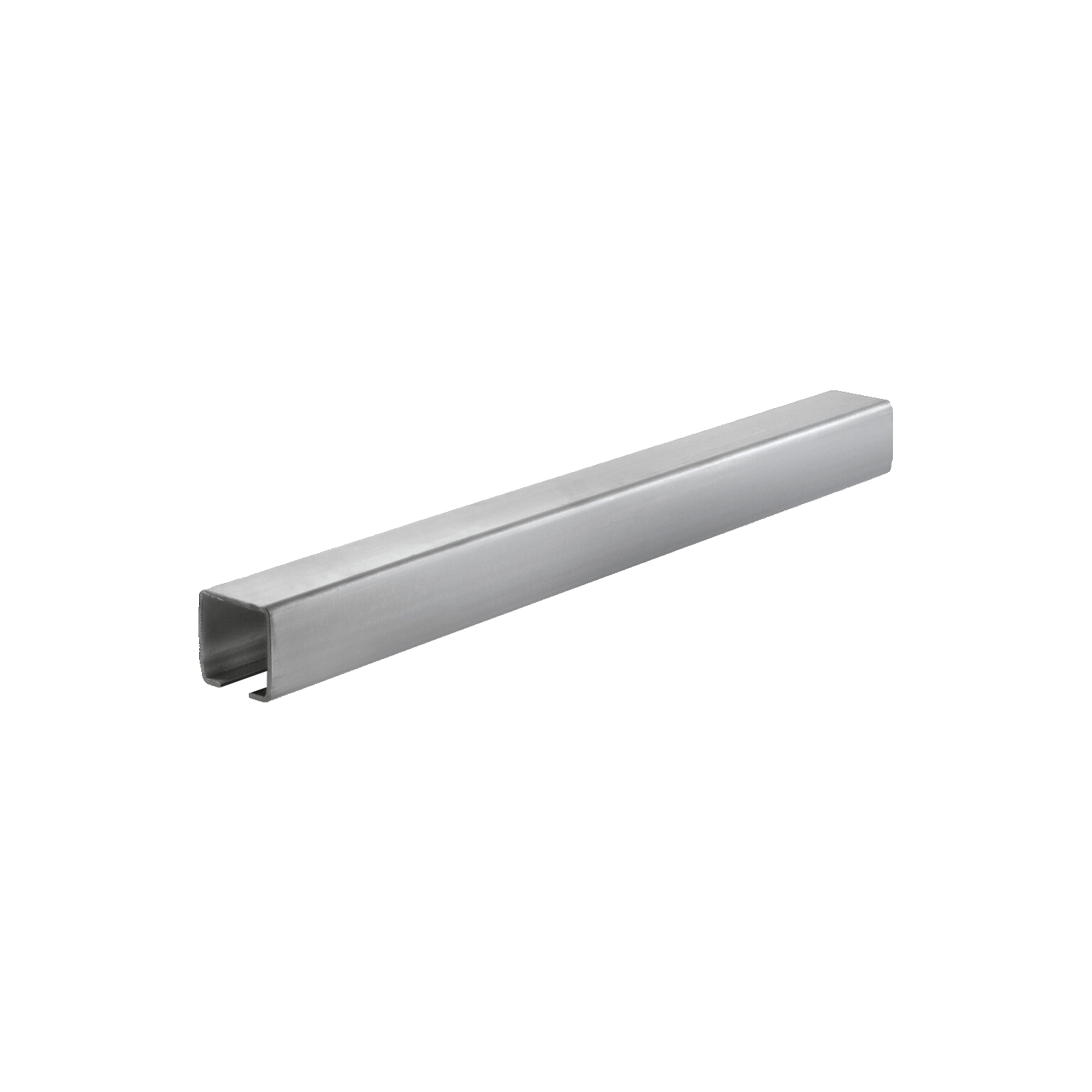

600 mm

Why You Should Use 90° Bends for Your Overhead Conveyor System

Workstations are rarely arranged in a straight line, making it difficult to achieve perfectly linear cable routing. To ensure reliable energy or material supply to your workstations, even with unique spatial configurations, your overhead system must be adapted accordingly. This is where 90° bends come into play, allowing the rails to be directed in a different direction or routed around obstacles. These bends enable smooth and precise directional changes tailored to your specific workplace requirements.

The various designs of our 90° bends provide a more precise and flexible solution for your overhead conveyor system, making them essential for more efficient energy supply. At TORWEGGE, you’ll find a diverse selection of bend variations to suit your needs.

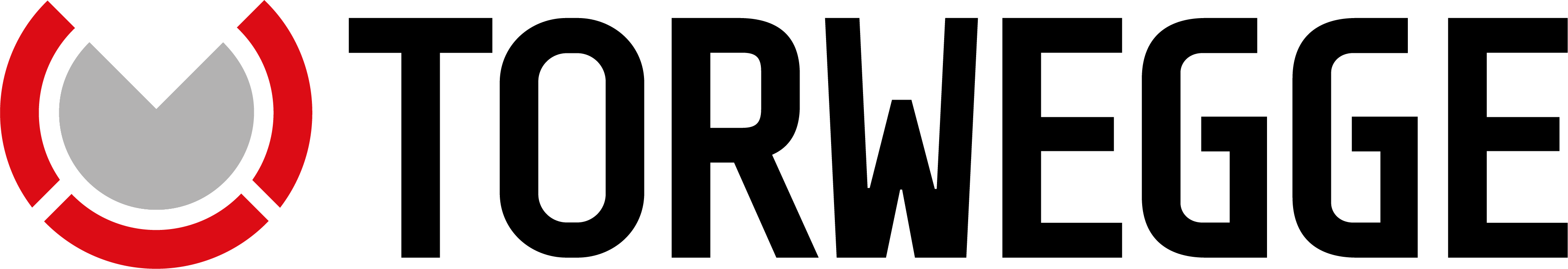

Galvanized 90° Bends for Durable and Reliable Operations

The galvanization of our overhead conveyor systems provides a protective barrier for your C-bends and rails, safeguarding them against corrosion, moisture, chemicals, and other operational wear. This means your system will have a longer lifespan and require fewer maintenance efforts or repairs, ultimately reducing your operating costs.

With various sizes and rail types available, you’ll find the perfect solution to adapt your rail system for optimal workstation support. Our 90° bends stand out as flexible, durable, and reliable components, ensuring seamless and efficient operations in your workplace.

Custom Overhead Conveyor System Solutions with 90° Bends

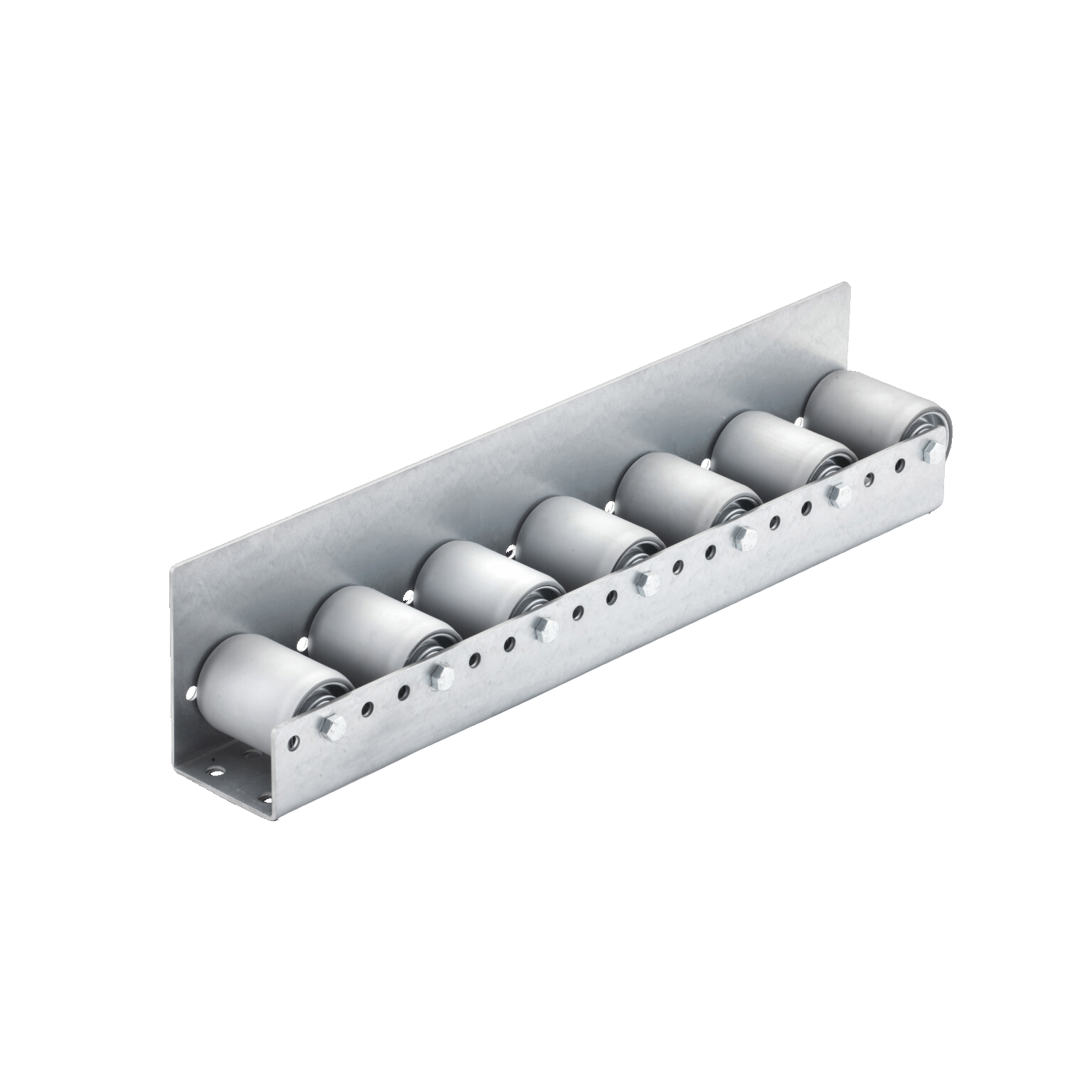

With our products, you can design your overhead conveyor system entirely according to your specific needs and requirements. This allows you to create safer and more efficient work and assembly stations, boosting your productivity. In addition to C-rails and 90° bends, we also offer the necessary accessories, enabling you to assemble the system independently. Simply browse our product range to find everything you need.

Our selection includes a variety of galvanized rail connectors, rail holders, transport hangers, track switches, and other components. When planning your overhead conveyor system, it’s important to carefully consider your requirements and spatial conditions to select only the components and models you truly need.

Our modular system makes it easy to plan and implement a customized solution tailored to your specific handling technology needs.

Buy High-Quality 90° Bends at TORWEGGE

The detailed planning of an overhead conveyor system involves numerous possible combinations of components, not all of which may suit your specific requirements. That’s why we’re here to support you throughout both the planning and implementation phases with expert advice and guidance.

Our contact center team brings years of experience and expertise in overhead conveyor systems. We can help you determine the exact number of 90° bends you’ll need and their ideal placement within your rail system. All your requirements and preferences, along with external factors like room size, wall layout, and more, are actively considered during the planning process.

Reach out to our customer service team via our contact form or service hotline for a consultation offer, and we’ll get back to you as soon as possible. Together, we’ll develop the best solution tailored to your needs!