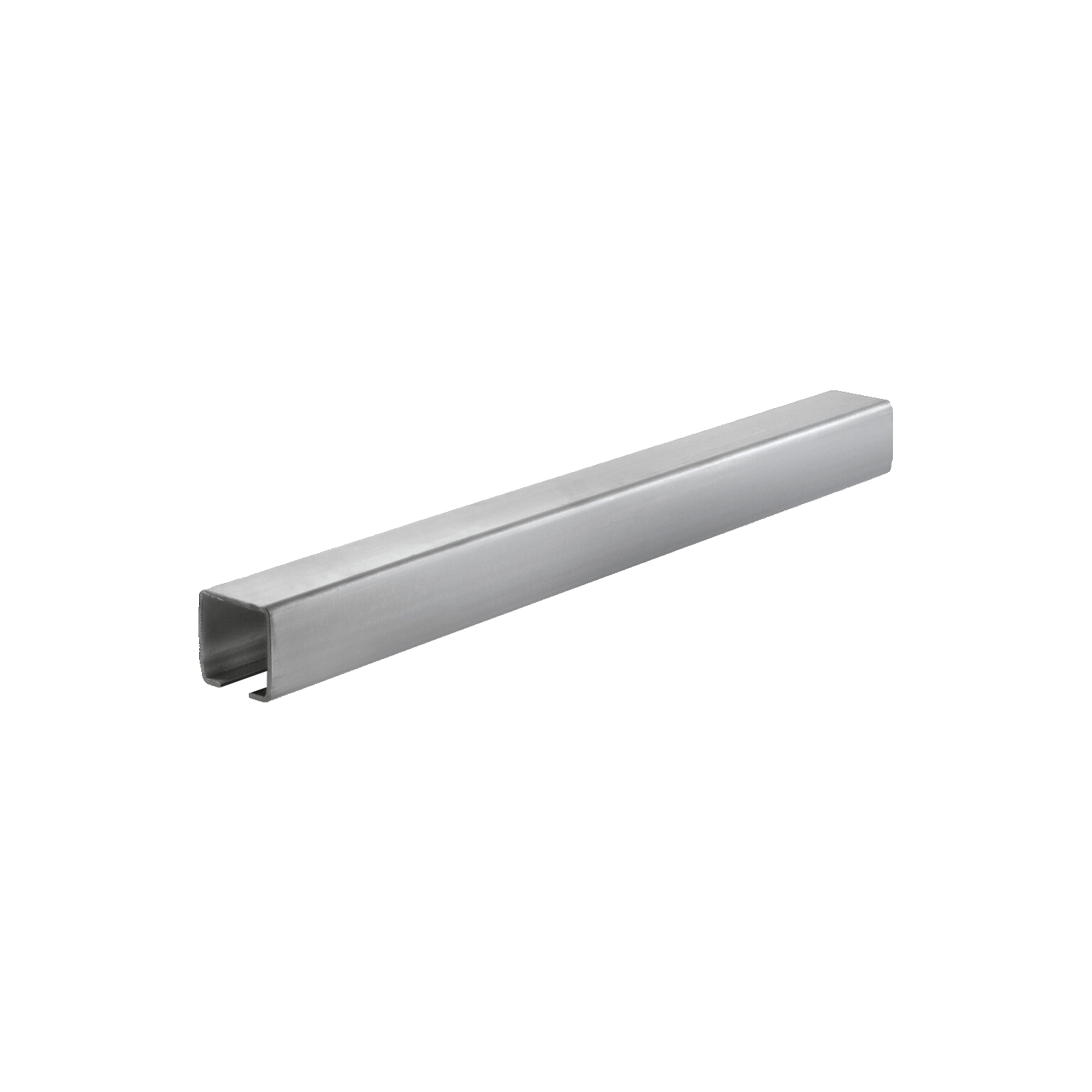

Order Roller Rails for Pallets at TORWEGGE

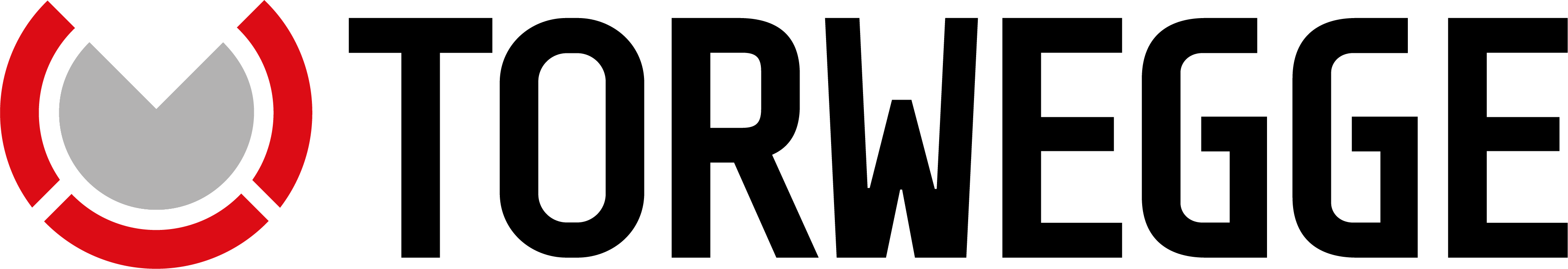

With the roller rails for pallets from TORWEGGE, you can move heavy goods seamlessly and efficiently. They offer the perfect solution for transporting heavy loads effortlessly, simplifying workflows across various applications. Especially in logistics, where heavy goods frequently need to be moved, these rails make it easier to handle (often loaded) pallets, saving you both effort and energy. See for yourself the benefits of our roller rails and purchase them in our online shop!

26 mm

2990 mm

26 mm

2990 mm

Advantages of Roller Rails for Pallets

Particularly on recurring routes in logistics, roller rails significantly simplify workflows. They can be used in flow racks, dynamic storage systems, or on floor conveyors, making them the ideal choice for cost-effective transportation of Euro pallets, industrial pallets, or mesh boxes in industrial and logistics operations.

In addition to their versatile applications, the simplified linear transport and flexible extension of the transport path are major advantages of pallet rails. You can decide how many rails to connect and thus determine the length of your conveyor route. Pallets can be transported either crosswise or lengthwise on the rails. Depending on your needs, you can either manually roll the goods to the next workstation or let gravity and the appropriate rail settings guide them to their destination. By using our products, you can link various workstations, saving both time and energy. For example, it's possible to separate storage and picking areas by integrating the rails into pallet racks. This not only reduces costs but also enhances workplace safety.

Increasing material flow and improving safety and ergonomics for employees are compelling reasons to use transport rails. Thanks to their durable and robust rollers, these transport rails are also the perfect solution for moving heavy goods. Maintenance and wear effort remain minimal as long as the load limits of the rollers are observed.

Versatile Designs for Optimal Use

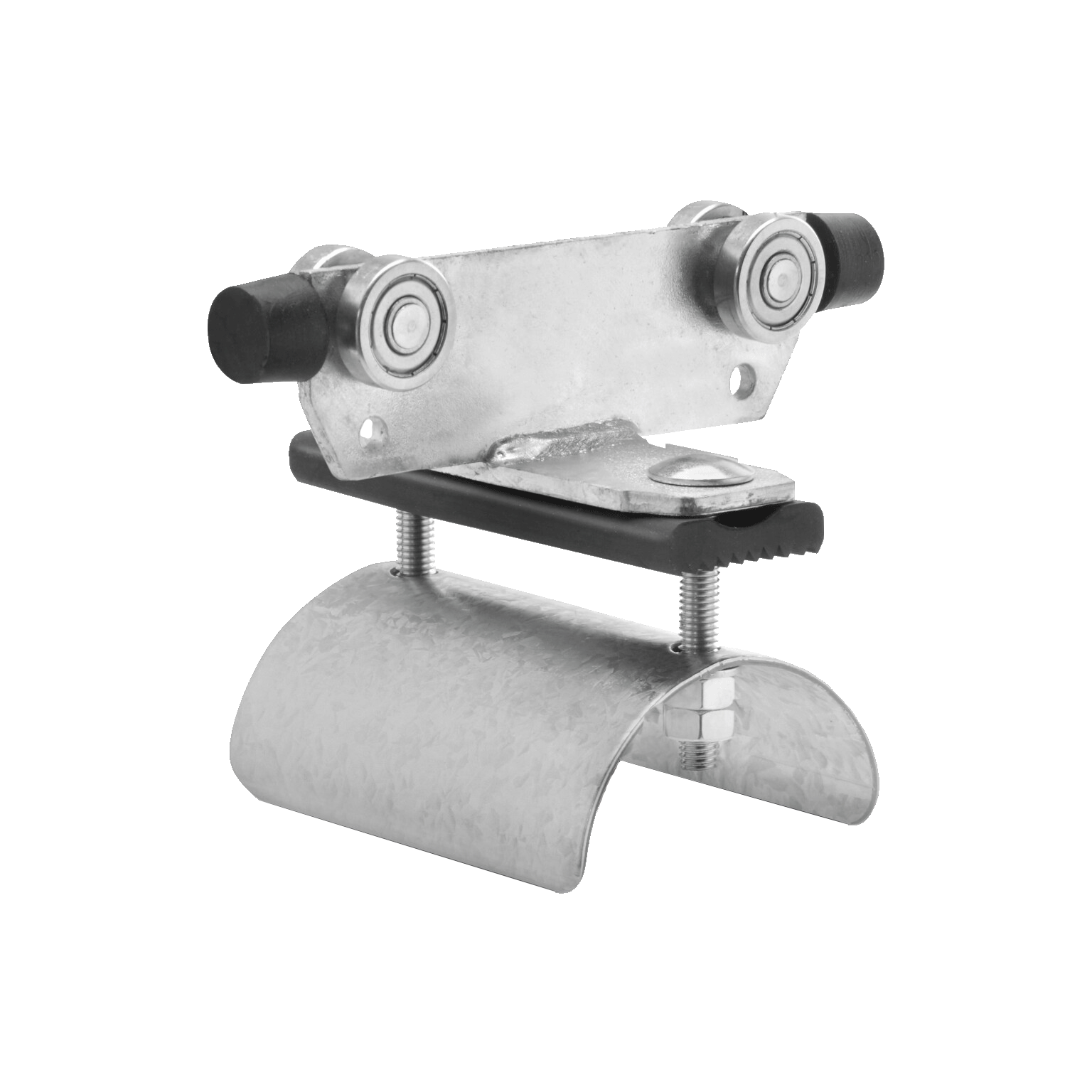

The steel rollers of our rails are robust and offer a high load capacity. Maintenance-free, durable ball bearings ensure smooth operation even under heavy loads. The profiles are made of galvanized steel sheet, providing high resistance to bending and torsion forces, while the galvanization ensures effective corrosion protection. The result is a robust and long-lasting transport solution that, combined with the necessary accessories, can be flexibly integrated into intralogistics.

To ensure the secure rolling of freight, we offer models with a raised profile on one side, providing the necessary side guidance. Additionally, you can use steel rollers with flanges to guarantee precise alignment of the freight along the rail track.

Different Roller Spacings

The spacing, or pitch, between the rollers on the rail significantly affects the product's price and performance. A larger pitch requires fewer rollers, which reduces production costs. However, with more rollers, the load is distributed more evenly, resulting in increased load capacity. For this reason, excessive roller spacing can make it difficult to move the transported goods smoothly.

It is essential to select the appropriate pitch depending on the weight of the freight being transported. Our roller rails are available in various pitches ranging from 52 mm to 208 mm, depending on the design.